24 TS 55 EQ Circular Saw

Troubleshooting

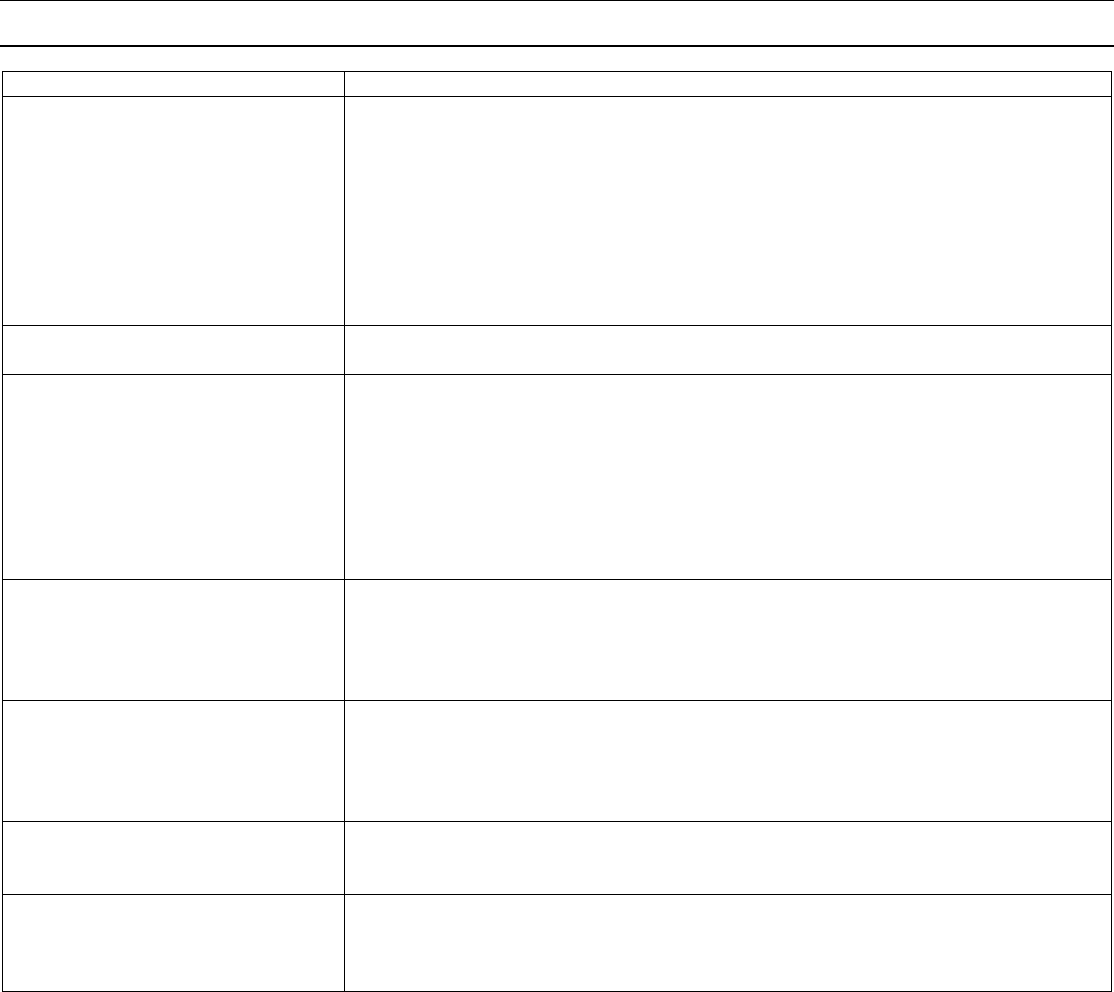

Symptom Possible Causes

Motor does not start 1. Check that the cord is properly plugged into an outlet.

2. Make sure the outlet has power. Check the circuit breaker or try another outlet.

3. If used with a Festool dust extractor, make sure the selector switch is pointing to

"Auto". The auxiliary outlet on the dust extractor has power only when the

selector is at Auto.

4. Inspect the power cord (including extension cords) for damage or missing

prongs.

5. The motor brushes may have worn and need replacement.

The guide rail gib cams won’t stay

tight

► The cams may be worn and have a flat-spot. Replace the cams.

► The friction washers may be worn or missing.

The saw makes a "Growling" sound

when it is first turned on or idling.

This sound is normal and expected. It is the result of the gears in the saw's heavy

duty drivetrain reacting to the speed control of the motor.

The electronic controller in the motor controls the motor speed by turning it On

and Off very rapidly. This form of speed control is called "Pulse-Width

Modulation" (PWM), and is common in most power tools with a variable speed

control. When there is no load on the sawblade, the pulsations of the motor cause

the gears to rapidly engage and disengage (called backlash), and this is the sound

you are hearing.

The saw makes wavy cuts ► Make sure the guide rail gib cams are properly adjusted.

► Inspect the blade for damage.

► Make sure the sole plate is not rocking on the guide rail.

► Keep the blade depth consistent during the cut; don’t raise and lower the blade.

► Forcing an ATB-type blade into the cut too fast can cause the blade to deflect.

Saw cuts are burning ► Make sure to use the correct blade for the material.

► Make sure the blade is sharp.

► Make sure the blade is installed correctly (not turning backward).

► Reduce the motor speed.

► If possible, increase the blade depth.

Excessive chipping on the lower

edge of the cut

► Make sure to use the correct blade for the type of material and type of cut.

► A very shallow blade depth can cause chipping on the underside if the teeth are

barely protruding below the surface. Increase the blade depth.

Excessive chipping on the top edge

of the cut

► Make sure to use the correct blade for the type of material and type of cut.

► Inspect the splinter guard. Make sure it is flush with the cut line for its entire

length.

► Materials prone to splintering may splinter more if the blade is set too deep.