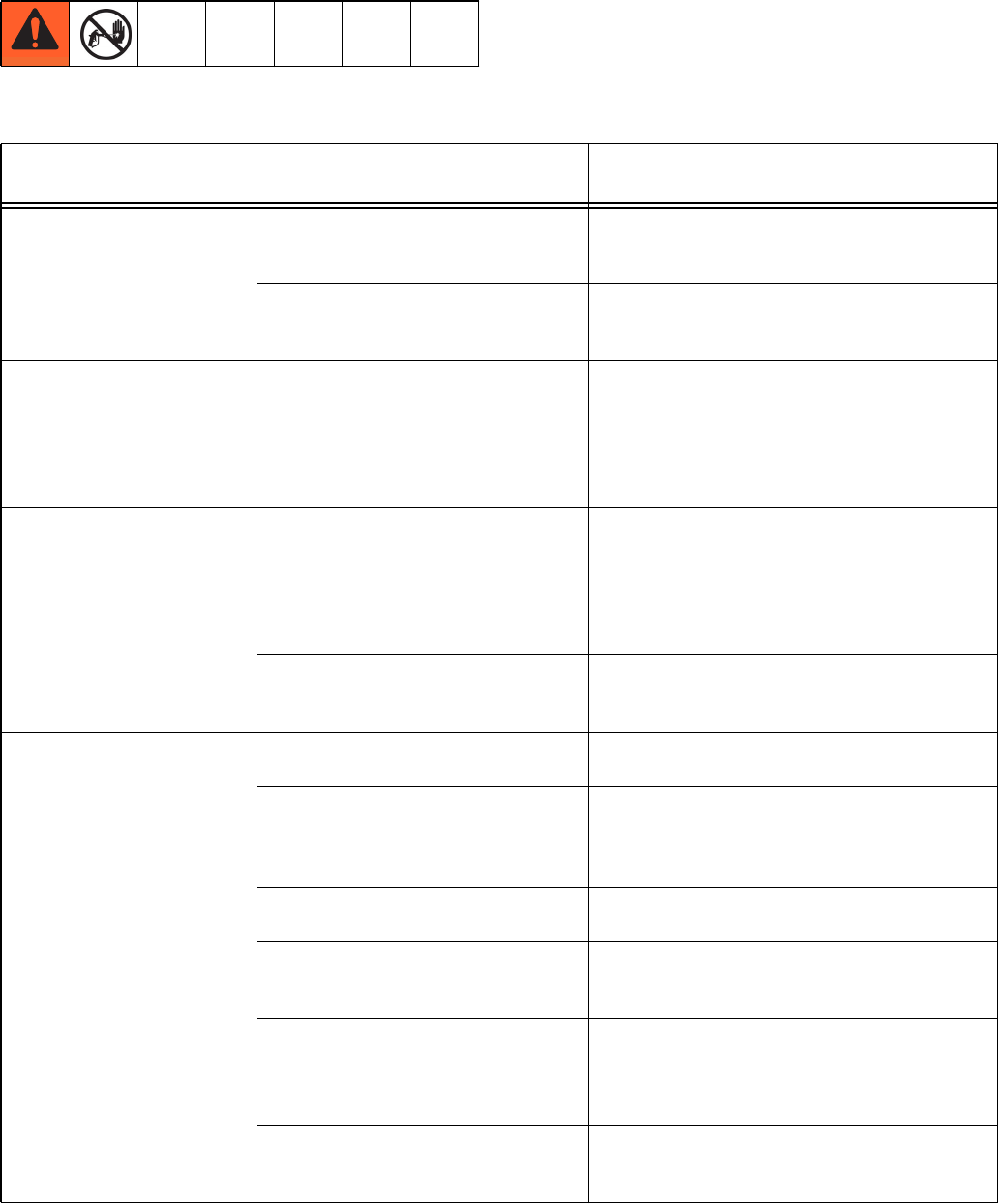

Troubleshooting

8 309977H

Troubleshooting

Relieve pressure; page 6.

MOTOR WON’T OPERATE.

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK, refer to this column

Basic Fluid Pressure Prob-

lems

1. Pressure control knob setting.

Motor will not run if at minimum

setting (fully counterclockwise).

1. Slowly increase pressure setting to see if

motor starts.

2. Spray tip or fluid filter may be

clogged.

2. Relieve pressure and clear clog or clean

filter; refer to separate gun or tip instruc-

tion manual.

Basic Mechanical Problems 1. Pump (31) for frozen or hardened

paint.

1. Thaw sprayer if water or water-based paint

has frozen in the sprayer. Place sprayer in

warm area to thaw. Do not start sprayer

until thawed completely. If paint hardened

(dried) in sprayer, replace pump packing.

See Pump Repair, page 20.

2. Displacement pump connecting

rod pin (75). Pin must be com-

pletely pushed into connecting

rod (45) and retaining spring (76)

must be firmly in groove of pump

pin. See Fig. 9.

2. Push pin into place and secure with spring

retainer.

3. Motor (33). Remove drive hous-

ing assembly (37). See page 15.

Try to rotate fan by hand.

3. Replace motor (33) if fan won’t turn. See

page 15.

Basic Electrical Problems 1. Motor control board. Board shuts

down and displays error.

1. See Motor Control Board Diagnostics,

page 17.

2. Electrical supply. Meter must

read: 210-255 Vac for 220-240

Vac models; 85-130 Vac for

100-120 Vac models.

2. Reset building circuit breaker; replace

building fuse. Try another outlet.

3. Extension cord. Check extension

cord continuity with volt meter.

3. Replace extension cord.

4. Sprayer power supply cord.

Inspect for damage such as bro-

ken insulation or wires.

4. Replace power supply cord.

5. That motor leads are securely

fastened and properly mated.

5. Replace loose terminals; crimp to leads.

Be sure terminals are firmly connected.

Clean circuit board terminals, Securely

reconnect leads.

6. For loose motor brush lead con-

nections and terminals. See

page 14.

6. Tighten terminal screws. Replace brushes

if leads are damaged. See page 15.