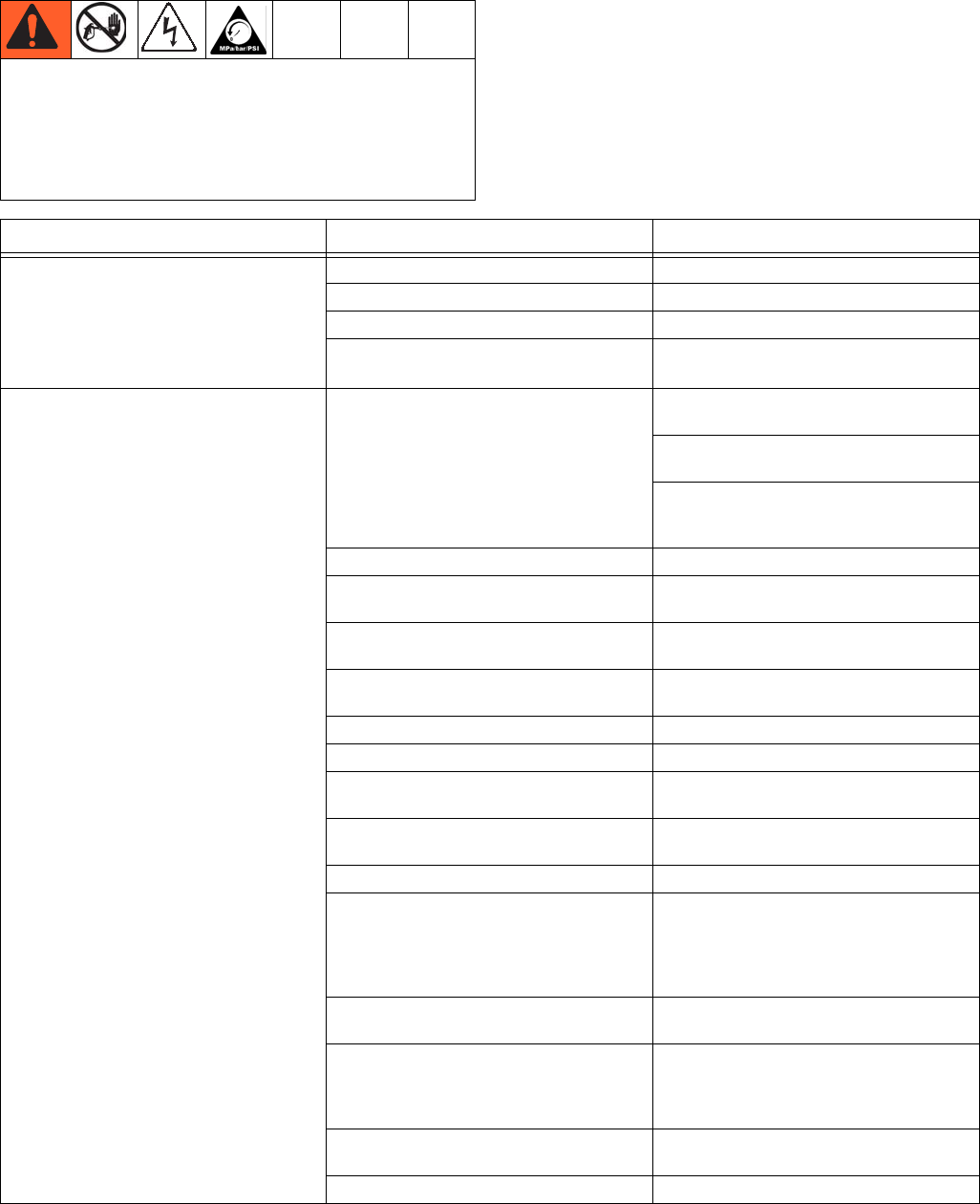

Troubleshooting

24 3A2587H

Troubleshooting

Check everything in this Troubleshooting Table before you

bring the sprayer to an authorized service center.

This equipment stays pressurized until pressure is manually

relieved. To help prevent serious injury from pressurized

fluid, such as skin injection, splashing fluid and moving

parts, follow the Pressure Relief Procedure when you stop

spraying and before cleaning, checking, or servicing the

equipment.

Problem Cause Solution

Sprayer makes no sound when

trigger is pulled

Trigger is locked. Disengage trigger lock. See page 8.

Power supply. Verify power to sprayer.

Motor has overheated. Wait 20-30 minutes for motor to cool.

Sprayer circuit breaker has interrupted power. Push and hold Circuit Reset Button (page 6)

to restore power to sprayer.

Sprayer makes sound but no material is

sprayed when trigger is pulled

Sprayer is not primed. Prime the pump. See Starting a New Job

(or Refilling the Material Cup), page 11.

Use pump access armor storage/startup tool to

clear pump of debris. See Storage, page 17.

Clean air vent holes or the air vent valve as your

model is equipped. See Shutdown and

Cleaning, page 15.

Prime/spray valve is in UP position. Put valve DOWN to spray position.

Flexible suction tube is missing or improperly

installed.

Make sure flexible suction tube is properly

installed.

Flexible suction tube strainer or vent valve or

vent holes are clogged.

See Shutdown and Cleaning, page 15.

Flexible suction tube o-rings are damaged or

missing.

Replace flexible suction tube o-rings.

Flexible suction tube damaged. Replace flexible suction tube.

Spray tip is not in SPRAY position. Turn spray tip to SPRAY position.

Spray tip is clogged. See Unclogging Spray Tip/Guard

Assembly, page 14.

Spray tip filter is clogged. Remove and clean spray tip filter. See Unclog-

ging Spray Tip/Guard Assembly, page 14.

Pressure control knob is too low. Turn pressure control knob up.

Sprayer has been tilted too far and suction tube

has lost contact with material.

Make sure material cup is filled with material.

Rotate flexible suction tube, page 9. Do not tilt

the material cup too far. Prime the pump. See

Starting a new Job (or Refilling the Material

Cup), page 11.

No or low material in material cup. Refill material cup with material and prime the

pump.

Inlet valve is stuck from material residue left in

sprayer.

Use pump access armor storage/startup tool to

clear pump of debris. If unsuccessful, see

Storage, page 17. See Inlet Valve

Removal/Service, page 21.

Pump is clogged, frozen, or has debris inside. See Outlet Valve Fitting Repair, page 22 and

Inlet Valve Removal/Service, page 21.

Material is leaking from hole in front of sprayer. Replace needle assembly.