Shutdown and Cleaning

3A2589D 15

Shutdown and Cleaning

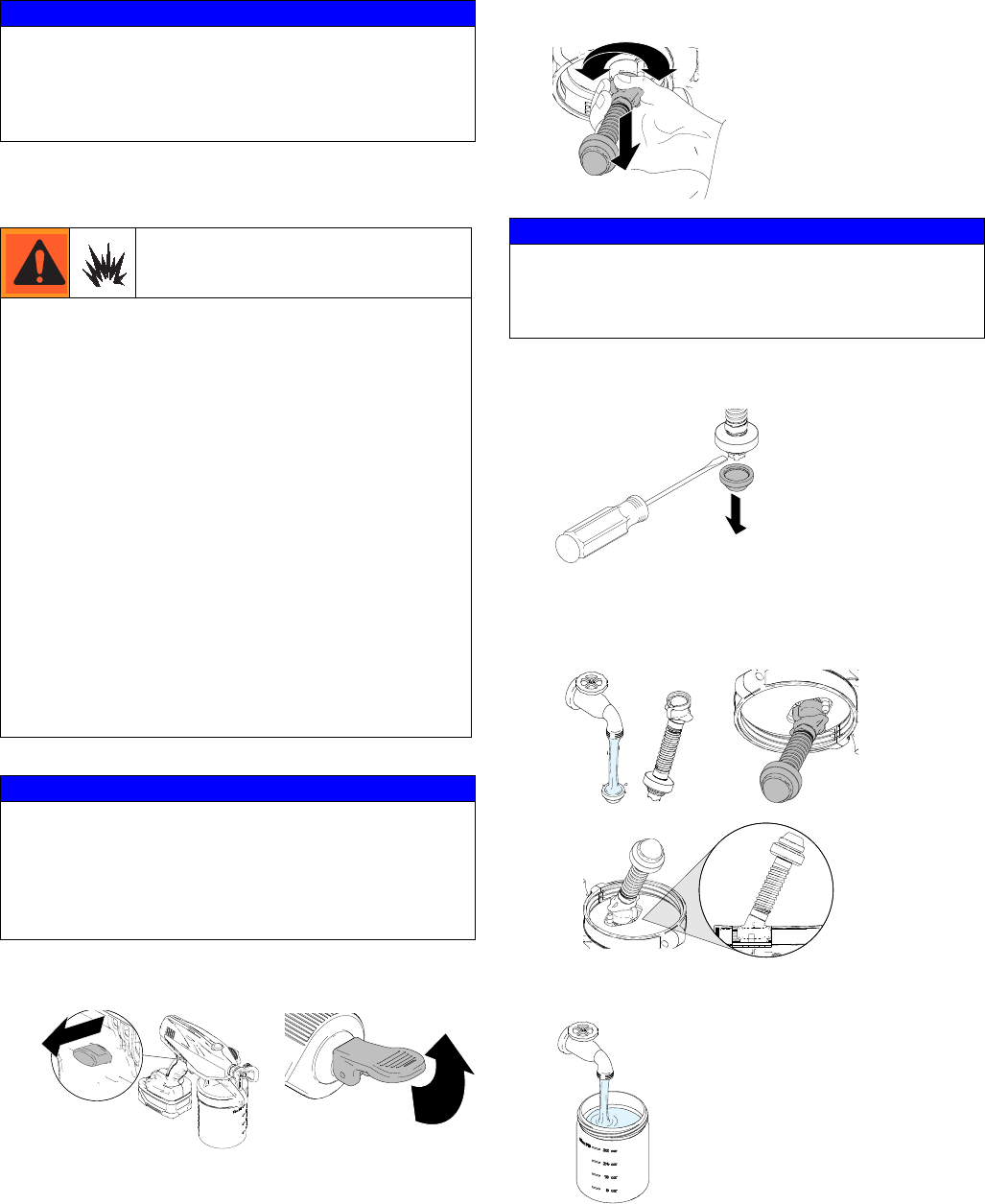

Flushing Sprayer

1. Engage trigger lock and pull prime/spray valve UP to

release pressure.

2. Remove material cup and return excess material to

proper container. If used, properly dispose the material

cup liner.

3. Remove flexible suction tube as shown below.

4. Use screwdriver to pry suction tube strainer from flexi-

ble suction tube.

5. Clean flexible suction tube and suction tube strainer

with water (or flushing fluid) and a brush every time

you flush the sprayer. Reconnect flexible suction tube

and suction tube strainer and orient as shown.

6. Clean material cup if not using a liner, and fill with

water or appropriate flushing fluid.

NOTICE

Failure to properly clean sprayer after each use will

result in hardened materials, damage to the sprayer, and

the warranty will no longer be valid. Do not store solvents

other than mineral spirits in sprayer. Always flush with

Graco Pump Armor prior to storage.

Use only water-based or mineral spirit-type materials

with flash point greater than 100° F (38° C). Do not use

materials which state “FLAMMABLE” on the packaging.

For more information about your material, request MSDS

from distributor or retailer.

Spraying certain materials may cause static build-up

in the sprayer that can result in static shock to the

user. If this occurs, first ensure the material has a flash

point greater than 100° F (38° C) and does not state that it

is FLAMMABLE anywhere on the package. If still feeling a

static shock, the material likely contains a non-mineral

spirits fluid such as, but not limited to, xylene, toluene, or

naphtha, which can build up static. Switch to an alterna-

tive material.

Use oil-based material outdoors or in a well-ventilated

indoor area with a flow of fresh air.

Keep spray area well-ventilated. Keep a good supply of

fresh air moving through the area.

NOTICE

Protect the internal parts of this sprayer from water.

Do not submerge the sprayer in cleaning fluid. Openings

in shroud allow cooling of mechanical parts and electron-

ics inside. If water or cleaning fluid gets into these open-

ings, the sprayer could malfunction or become

permanently damaged.

ti14999a

ti16700a

ti18866a

NOTICE

When removing flexible suction tube from sprayer, make

sure to pull directly on top fitting of flexible suction tube.

Flexible suction tube will become damaged if pulled from

bottom or on flexible portion.

ti19033a

ti18952a

ti15002a

ti18859a

ti19467a

ti19463a

ti15001a