Pressure Relief Procedure

20 3A0420H

Pressure Relief Procedure

Relieve A and B Fluid Pressure

1. Engage the trigger lock.

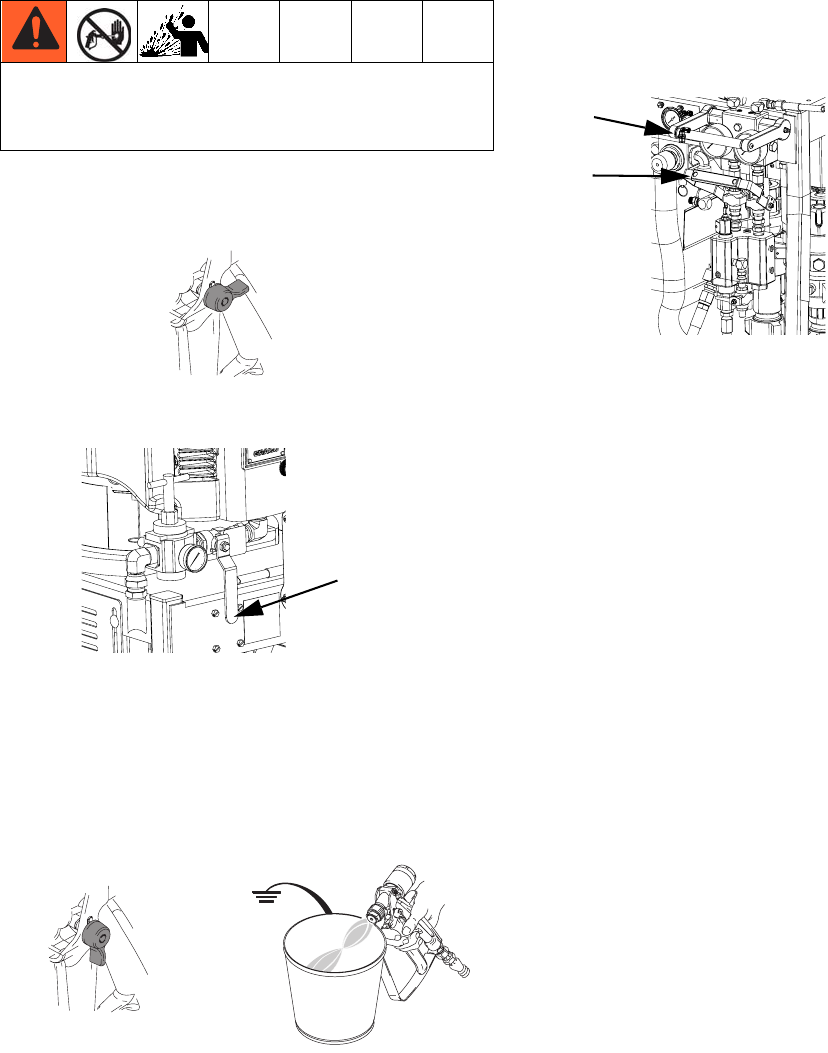

2. Close the main air shutoff valve (CA).

3. Shut off heaters, if used.

4. Shut off feed pumps, if used.

5. Remove the spray tip and clean.

6. Disengage the trigger lock.

7. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

8. Engage the trigger lock.

9. Close the dual shutoff handle (AE) and open the cir-

culation handle (AC).

10. Always flush the mix hose after relieving A and B

fluid pressure through the mix manifold. See Flush

Mixed Material, page 26.

11. Shutoff the solvent supply pump and repeat steps

6-8 to relieve solvent pressure.

If the mixed material has already been flushed, but

pressure remains on the A and B pumps, pressure

can be relieved back to the hoppers (J).

a. Close the main air shutoff valve (CA).

b. Open the circulation handle (AC).

NOTE: For longer valve life in abrasive fluids, it is

advisable to relieve high pressure out through the

gun when possible.

12. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after follow-

ing the steps above, very slowly loosen tip guard

retaining nut or hose end coupling to relieve pres-

sure gradually, then loosen completely. Clear hose

or tip obstruction.

13. If static mixer, whip hose, and gun cannot be flushed

because of mixed and cured material, very slowly

loosen static mixer tube from mix manifold outlet to

relieve pressure gradually, then loosen completely.

Replace or clean clogged components.

Follow Flush Mixed Material, page 26 when you

stop spraying or dispensing; and before cleaning,

checking, servicing, or transporting equipment.

TI1949a

CA

r_571100_3A0420A_11a-1

TI1950a

TI1953a

AC

AE

r_571101_3A0420A_9a-2