308-34117

Troubleshooting

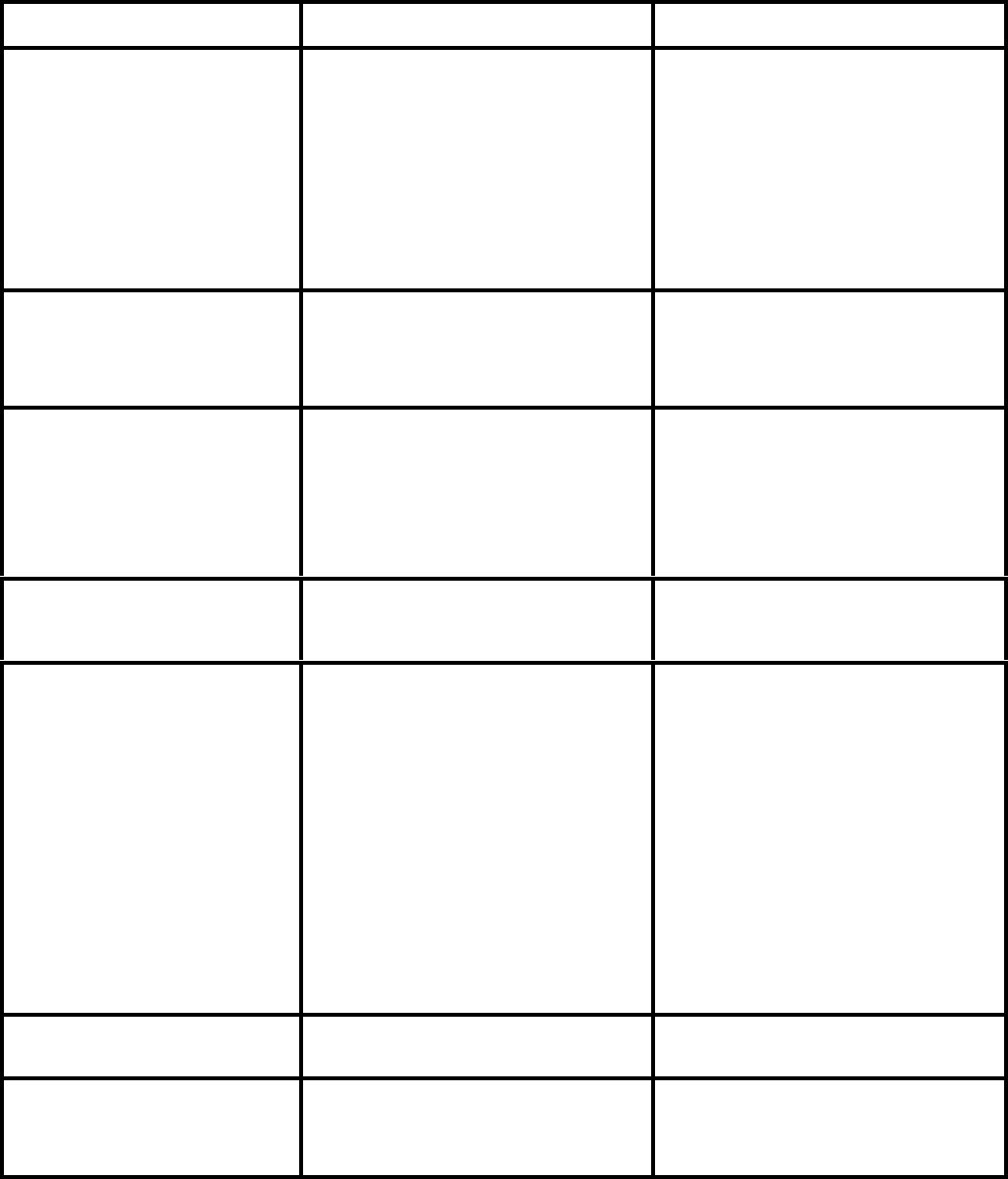

PROBLEM CAUSE SOLUTION

Fluid

flow is fluttering while

spraying

1.

Fluid nozzle is not tight enough

2.

Fluid filter is clogged

3.

Fluid adjustment knob is not

properly set

4. Baffle (item 11) is installed wrong or

damaged

1. See page 8 to install the fluid nozzle

correctly

2. Check

the fluid filter

3. Adjust the fluid adjustment knob for

less feathering or use a larger size

nozzle

4. Check

if the baf

fle protrusion is proper

-

ly

inserted into the gun insert hole,

see

page 19; replace

the

baf

fle if damaged

Fluid

flow fades while spraying

high viscosity fluids

1. Air

hose size is too

restricted for higher

air flows

2.

Fluid pressure is too low

1. Use

larger 3/8 in. ID air hose; order part

no.

185–353

2. Raise

the fluid supply pressure or

use

a

smaller fluid nozzle

Pattern becomes of

f-set or heavy

on ends

1.

Fluid nozzle is too tight

2.

Air cap is too tight

3.

Air cap horn holes are plugged

1. See page 8 to install the fluid nozzle

correctly; replace the nozzle if

damaged

2. Loosen

the air cap retaining ring

3. Clean the air cap horn holes with a

non-metallic

item, such as a toothpick

Fluid

system will not operate at low

enough fluid pressure [below

10 psi (0.7 bar)]

There is no fluid regulator

, or the air regu

-

lator on the pressure pot is not sensitive

enough at low pressures

Add a low pressure fluid regulator on the

fluid line or add a more sensitive air regu

-

lator on the pressure pot.

Adhesive residue forms on spray

nozzle

1. Activator

is dispensing

in the atomizing

air

2. Activator

valve is leaking or not seating

properly

3. Baffle

(item 1

1)

is leaking at baf

fle pro

-

trusion

4. Baffle

is leaking at nozzle seal

5. Air cap taper is not sealing to nozzle

taper

1. Do

not trigger the gun with the activator

on

and atomizing air of

f

2. Clean

the needle,

seat, and packings;

lubricate

packings and re-assemble

3. Clean

and re-assemble

the baf

fle with

a

small amount of

PTFE

r

pipe sealant

on the baffle protrusion or replace

the

baffle.

Make sure that the baf

fle protru

-

sion is properly inserted into the gun

insert

hole, see page 19

4. Clean the baffle and replace the

nozzle

seal

5.

Clean and re-tighten the air cap

Adhesive collecting in air passages

The adhesive nozzle’

s internal seal is

leaking

Clean the nozzle and seat; see page 8

to install the fluid nozzle correctly

When the gun is triggered, the

adhesive dispenses before the ac

-

tivator or the activator dispenses

before the adhesive

Activator needle hex nuts are not tight Adjust the activator needle hex nuts until

the adhesive and activator needles open

together