8308-341

Setup

and Shutdown

Removing and Installing the Fluid Nozzle

Follow

this procedure whenever you remove and install

a fluid nozzle. See page 4 to select a nozzle or

needle/nozzle/air cap kit.

1.

Follow the

Pressure Relief Procedure

on

page 7.

2.

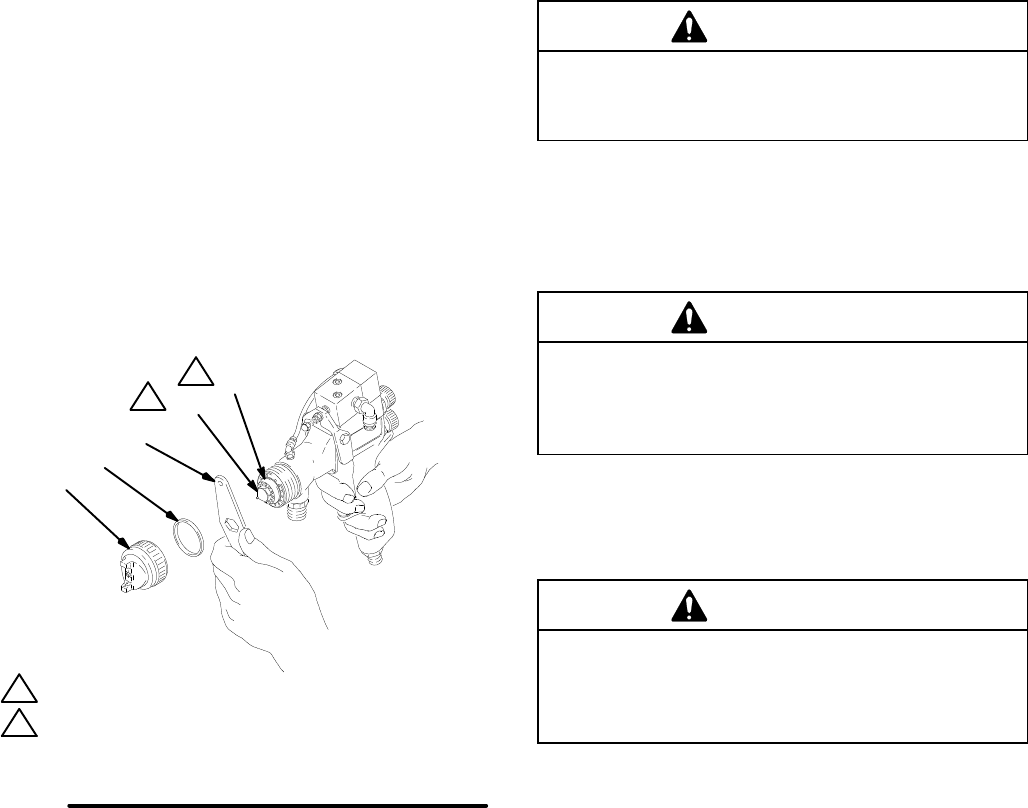

Remove the air cap ring (12), air cap (19), and air

cap seal (47). See Fig. 5.

3. T

rigger the gun while you remove the fluid nozzle

(20) with the gun wrench (35).

Fig. 5

02757A

35

20

12, 19

47

17

Lightly

lubricate baf

fle o-ring (17)

Apply

PTFE

adhesive to nozzle (20) threads. T

rigger gun and

tighten

to 125–150 in-lbs (14–17 N

Sm)

2

1

1

2

CAUTION

Trigger

the gun whenever you tighten or remove the

fluid nozzle (20) to pull the needle away from the

nozzle seating surface and avoid scratching it.

4.

Apply PTFE

r

adhesive to the threads of the fluid

nozzle (20) you are installing.

5.

Lubricate the baf

fle o-ring (17).

CAUTION

Lubricate the baf

fle o-ring (17) before installing the

fluid nozzle (20). A dry o-ring will prevent the nozzle

from tightening properly and adhesive may leak

inside the gun.

6. T

rigger the gun while you install the fluid nozzle

(20) with the gun wrench (35). T

ighten it to 125 to

150 in-lbs (14 to 17 N

Sm).

CAUTION

When tightening the fluid nozzle (20), do not

exceed

150 in-lbs (17 N

S

m) torque. Over-tightening can

damage the nozzle, af

fect the spray pattern, and is

unnecessary to guarantee a seal.

7.

Install the air cap seal (47), air cap ring (12), and

air cap (19).