Maintenance

24 313872B

Maintenance

Supplied Tool Kit

See Parts on page 42 for tool illustrations.

• Hex Nut Driver; 5/16

• Screwdriver; 1/8 blade

• Impingement Port Drill Bit; various sizes depending

on port size

• 117661 Pin Vise; dual reversible chucks,

see FIG.14

• 118665 Fusion grease

Lubrication

See Accessories on page 53 to order lubricant. Liber-

ally lubricate all o-rings, seals, and threads.

Bleed Throat Seal Liquid

Cartridge

To effectively coat the purge rod, air must be bled out of

the TSL cartridge weekly. Perform this procedure after

replacing the mix module or front end to bleed TSL from

cartridge. Before replacing the mix module or front end,

bleed all TSL to prevent spilling TSL.

1. With bleed port facing away from you and with air

supply connected, use a 5/16 in. nut driver (sup-

plied) to slowly open the bleed valve 1/4 to 1/2 turn

until air/fluid begins to slowly exit the valve. See FIG.

15.

2. When no more air comes out of the bleed valve,

close the bleed valve.

Procedure Schedule

Bleed Throat Seal Liquid Car-

tridge, page 24

Weekly

Replace Mix Chamber and Front

Seal, see page 30

Every 2-4

Weeks

Clean Clean Check Valves, page 27 Monthly

Clean Outside of Gun, page 25 As Needed

Replace Throat Seal Liquid Car-

tridge, page 31

As Needed

Clean Breather Plug, page 26 As Needed

Clean Fluid Manifold, page 26 As Needed

Clean Fluid Housing Passages,

page 28

As Needed

Clean Orifice, page 29 As Needed

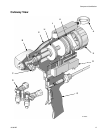

FIG. 14: Pin Vise

Reversible

Reversible

TI3684a

NOTICE

Use only Throat Seal Liquid on the o-rings, seals,

and threads of the Throat Seal Liquid cartridge.

Fusion grease or other petroleum-based or vegeta-

ble-based lubricants will cause cartridge o-rings

and seals to swell and stick.

FIG. 15: Open the Bleed Port

ti14478a