22 308741

Service

NOTE: To ensure proper alignment of the parts, follow

the next steps in the order they are given.

27. Slide the insert (4) into the spray housing (2a), and

install them onto the gun body (1). Align the hous-

ing with the slot and lip (A) on the gun body (1).

28. Tighten the hex nut (9) onto the insert (4) hand-

tight, then loosen the nut about one turn so the

insert (4) and spray housing sit loosely in the gun

body.

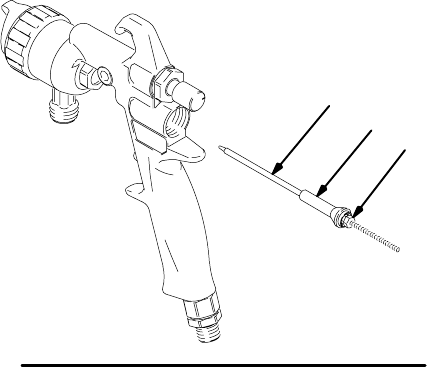

29. Check the fluid needle (13) for damage or exces-

sive wear. Replace needle tip or entire needle if

necessary.

30. Lubricate the outside of the new air valve assem-

bly (26) and place it on the fluid needle (13),

against the nut (B). See Fig. 32. This helps align

the entrance of the air valve stem into the inside

diameter of the u-cup (16) without damaging the

u-cup lip.

31. Install the fluid needle (13) and the air valve

assembly (26) into the back of the gun.

Fig. 32

13

26

B

32. Install the air valve spring (22). Point the gun down

to center the spring (22) and tighten the fluid nut

(19) to 125–135 in-lb (14–15 NSm).

33. Install the needle spring (23) and fluid adjustment

knob (21).

34. Install the trigger (10), pivot pin (17), and screw

(11). Torque the screw to 20–30 in-lb (2.3–3.4

NSm).

35. To avoid galling of the fluid nozzle seat in the insert

(4), apply a thin film of lubricant to the seat. Trigger

the gun while you install the fluid nozzle (12) with

the gun tool (28). Torque the nozzle securely to

145–155 in-lb (16–17 NSm).

36. Tighten the hex nut (9) securely to 125–135 in-lb

(14–15 NSm).

37. Install the pattern adjustment valve assembly (25).

Torque the nut (25a) to 125–135 in-lb (14–15

NSm).

38. To tighten the packing screw (8), turn the screw in

until it touches the fluid packings (5), then tighten

one full turn to pre-set the packings. Loosen the

screw, then turn it in until it touches the packings

again. Tighten the screw 1/12 turn more (equal to

half the distance between points on the hex head).

39. Trigger the gun to test the needle movement. If the

needle does not return after the trigger is released

or is slow in returning, loosen the packing screw

(8) until the needle returns freely.

40. Install the air cap (14) and air cap retaining ring

(15). Hand-tighten the ring.

41. Make sure the gun fluid packings are sealing

properly by spraying solvent at low pressure

before fully pressurizing the gun with the fluid to be

sprayed.

If the fluid packings leak, tighten the packing screw

(8) slightly and retest until the packings and fluid

needle seal completely.