34 308936

Service

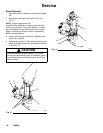

Fluid Needle Assembly Removal

1. Prepare the gun for service as instructed on page

28.

2. Remove the retaining nut (8), tip guard, (2), air cap

(1) and spray tip (9). See Fig. 7, page 29. You may

have to turn the air cap with the tip guard to

remove the air cap from the gun.

3. Trigger the gun and remove the seat housing (21)

with the 9 mm driver (64). See Fig. 8, page 29.

4. Remove the barrel as instructed on page 32.

5. Remove the trigger screws (4) and trigger (13).

6. Place the 2 mm driver (58) in the back of the fluid

needle assembly (28). See Fig. 14. Push the tool

in and turn it counterclockwise about 12 full turns

to unthread the needle.

7. Insert the 2 mm driver (58) into the front of the gun

and push the fluid needle assembly (28) out the

back of the gun body.

CAUTION

To avoid damaging the needle assembly, be sure the

needle is completely unthreaded before pushing it

out of the barrel.

8. Install the fluid needle assembly (28) into the gun

barrel. See Fig. 15. Push in on the needle with the

2 mm driver (58) and tighten the assembly clock-

wise until just snug, then 1/4 to 1/2 turn tighter.

9. Install the trigger (13) and tighten the trigger

screws (4).

10. Assemble the barrel as instructed on page 36.

11. Trigger the gun and install the seat housing (21)

with the 9 mm driver (64). Tighten the seat housing

until it’s snug and then tighten it 1/8 turn more.

CAUTION

To avoid damaging the seat housing and gun barrel,

never over-tighten the seat housing. Over-tightening

may result in improper fluid shut-off.

12. Assemble the spray tip, air cap, and tip guard.

Then install them on the gun, securing them with

the retaining nut. Tighten the retaining nut firmly.

13. Test the gun resistance as instructed on page 25.

Fig. 15

28

13

4

02016