-30-

G0492 12" X 36" Combo Lathe/Mill

Your lathe is capable of cutting inch and metric

threads.

To setup for threading:

1. DISCONNECT THE LATHE/MILL FROM

POWER!

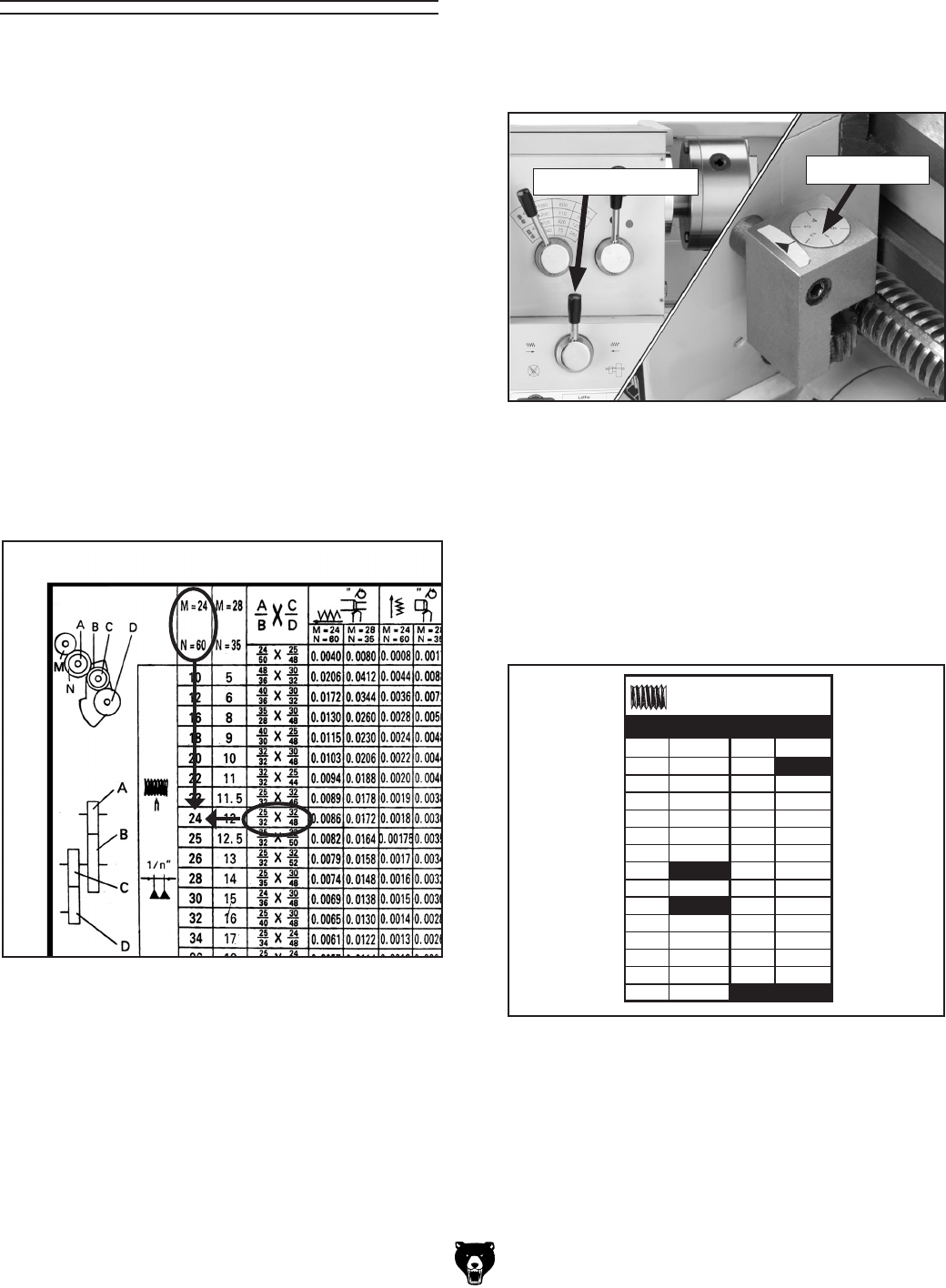

2. Refer to the Change Gear Chart on Page 31

or the chart on the inside of the change gear

door to determine the needed combination

of gears and which spindle location to install

each gear on.

See

Figure 36 for examples of how gear com-

binations can achieve your needed threading

rate. For example: The chart shows that 24

TPI is needed.

Note: All change gears are stamped with the

number of teeth they have.

Figure 36. Using the change gear chart.

Longitudinal

Feed

Cross

Feed

Inch

Threading

Setup for Threading

6. Use the leadscrew lever to select leadscrew

direction (

Figure 37).

7. Setup the cutting tool, compound rest, and

cross slide to cut your threads; and loosen the

apron lock

(Figure 35).

3. Loosen the lash adjuster (Figure 33) and

swing the assembly out of the way.

4. Remove the required E-clips, lubricate, and

swap out the appropriate change gears.

5. Move the lash adjuster so the gear backlash

is at 0.003" to 0.008", and tighten the lock

nut.

Figure 37. Threading controls.

Thread Dial

Leadscrew Lever

Figure 38. Thread dial table.

5

6

7

8

9

10

11

12

13

14

15

16

17

1-6

1 or 2

1 or

2

1 or

2

1 or 2

1 or 2

1 or

2

1 or

2

1 or 2

1 or

2

1 or

2

1 or

2

1 or

2

1 or

2

1

1

1

1

1

1

1

1-6

1-6

1-6

1-6

1-6

18

20

22

23

24

25

26

28

30

32

34

36

40

48

THREAD DIAL TABLE

LEAD SCREW PITCH 5 T.P.I.

12.5

11.5

T.P.I. DIAL T.P.I. DIAL

— If cutting inch threads, refer to the Thread

Dial Table in Figure

38 to use the thread

dial.

— If cutting metric threads, do not use the

thread dial. Instead, you must leave the

half nut engaged until the threading opera

-

tion is totally complete.

8. Loosen the apron lock bolt and use the feed

lever (

Figure 35).

9. While threading, keep your hand on the

half-nut lever, ready to disengage the apron

to avoid any potential for an apron/chuck

crash.