-42-

G0444/G0444Z 10" Table Saw

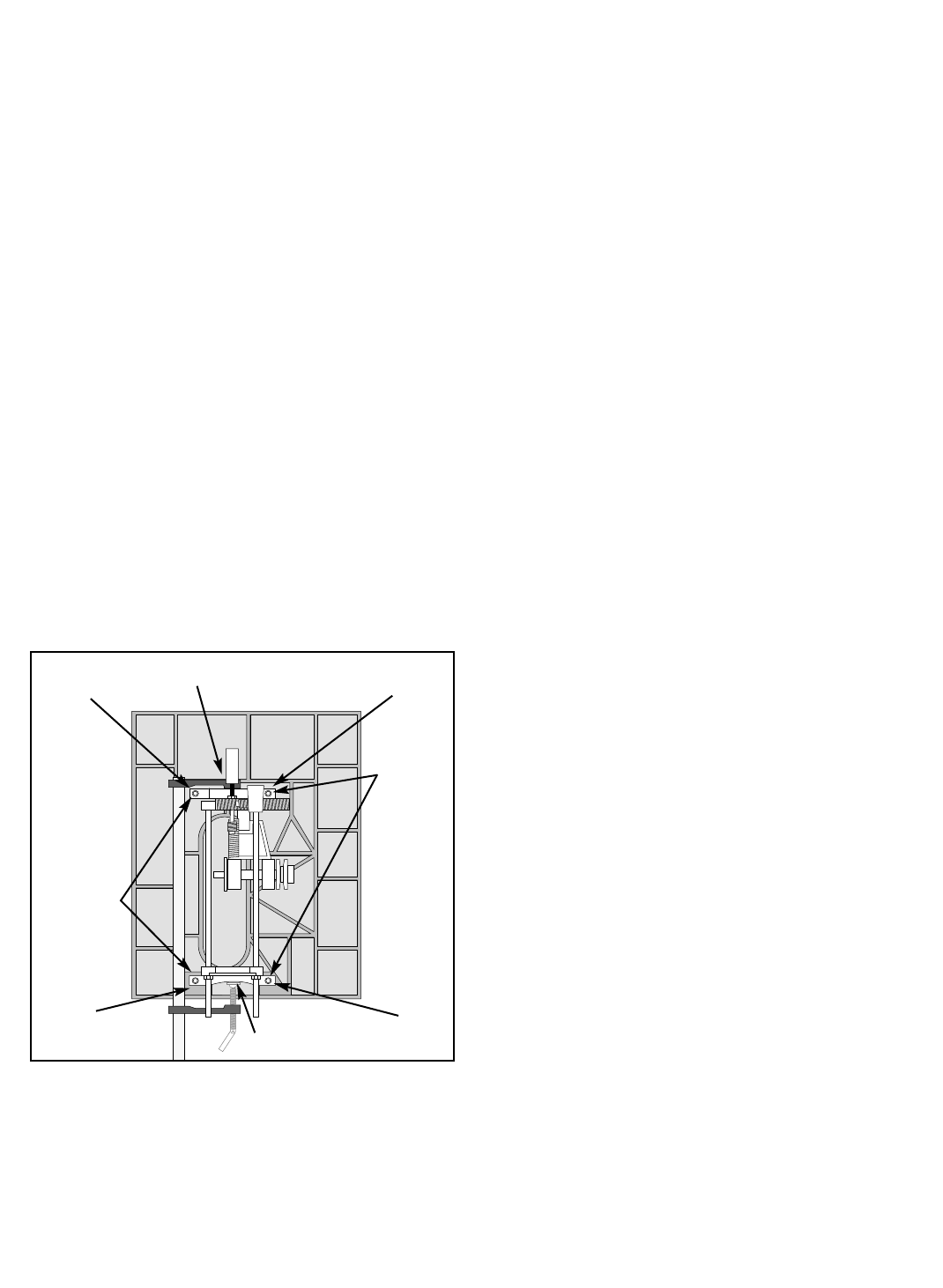

Figure 55. Underside view of

table/trunnion assembly.

6. Tilt the blade to 45° and repeat Steps 3-5.

— If the difference was less than 0.004"

when the blade was positioned at 90˚ and

45˚, then the blade parallelism is set cor-

rectly. Skip to the next sub-section.

— If the difference was greater than 0.004"

when the blade was positioned at 90˚ or

45˚, then the trunnion assembly below the

table needs to be adjusted. Continue with

the next step.

7. Remove the fence and the blade guard.

8. Lower the saw blade completely below the

table surface.

9. Flip the saw upside down on the floor.

Note—Lay clean and staple-free cardboard

or a blanket on the floor to prevent damage

to the cast iron table.

10. To maintain the trunnion assembly as one

unit, place a bar clamp across the entire

trunnion assembly as shown in Figure 55.

11. Refer back to the measurements taken in

steps 3-6.

— If the blade was not parallel in the 90˚

position, then proceed to the set of

instructions titled “To Shift The Trunnion.”

— If the blade was not parallel in the 45˚

position, then proceed to the set of

instructions titled “To Shim The Trunnion.”

To Shift The Trunnion:

1. Loosen the trunnion bolts (Figure 55).

2. Move the trunnion assembly according to the

difference measured when the blade was in

the 90˚ position.

3. Tighten the trunnion bolts.

4. Flip the saw rightside up and repeat steps 2-

6 on page 41.

5. Once the miter slot is adjusted parallel to the

blade, recheck all measurements and be

sure the table mounting bolts are secure.

6. Re-attach the blade guard and fence.

7. Verify that the blade guard is correctly

aligned with the blade.

To Shim The Trunnion:

1. Loosen the trunnion bolts (Figure 55).

2. Using Figures 56 & 57, shim the trunnion

assembly according to the difference mea-

sured when the blade was in the 45˚ posi-

tion.

— If the distance of A is shorter than B,

shim(s) will need to be placed under cor-

ners #1 and #2.

— If the distance of B is shorter than A,

shim(s) will need to be placed under cor-

ners #3 and #4.

Note—Very thin shim stock works well, just make

sure they are all the same thickness and you put

an equal number under each of the two corners.

Clamp Here

Clamp Here

Trunnion

Bolts

Trunnion

Bolts

#1 Shim

#3 Shim

#4 Shim

#2 Shim