-46-

G0460/G0461 12" Sliding Table Saw

5. Turn the handwheel until the blade and

square are flush from top to bottom.

6. Snug the 0° tilt stop nut against the leadscrew

nut and tighten the set screw.

7. Recheck the blade with the square to ensure

the nut has not been over-tightened.

8. Adjust the blade angle until you hit the 45°

positive stop. Check the bevel with an adjust

-

able square set to 45°.

9. If variations exist, loosen the set screw in the

45° tilt stop nut (

Figure 79) and adjust the

stop nut until the blade and square match.

10. Tighten the set screw and recheck the bevel

by adjusting the blade tilt to 0°, then back to

45°.

11. Check the scale for accuracy at 45° and 0°.

—If the scale reads 45° when the blade is at

45° and 0° when the blade is at 90° to the

table, it is accurate.

—If the scale reading does not match the

blade angle, move the tilt angle to 0° and

adjust the pointer on the scale to match the

reading.

Blade Tilt

The blade tilt is calibrated at the factory, but can

be adjusted if it changes during the life of the

machine.

To calibrate the blade tilt:

1. DISCONNECT SAW FROM POWER!

2. Move the blade tilt to 0° according to the

gauge, and raise the main blade as high as it

will go.

3. Place a machinist's square on the table sur-

face and between the blade teeth. Inspect for

gaps between the blade and the square.

4. If a gap exists at either the top or bottom of

the square, loosen the set screw in the 0° tilt

stop nut shown in

Figure 79.

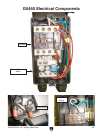

Figure 79. Blade tilt stop nuts.

0° Tilt

Stop Nut

45° Tilt Stop Nut

Leadscrew

Nut