-42-

G0500/G1018/G1018HW 8" Jointers

SYMPTOM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped cir-

cuit).

Machine slows when oper-

ating.

Loud, repetitious noise com-

ing from machine.

Snipe (gouge in the end of

the board that is uneven

with the rest of the cut)

Workpiece stops in the mid-

dle of the cut

Chipping

Fuzzy grain

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose connec-

tions.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connec-

tions.

3. Incorrect fuses or circuit breakers in

power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose connec-

tions.

2. Low voltage.

3. Incorrect fuses or circuit breakers in

power line.

4. Motor overloaded.

1. Applying too much pressure to work-

piece.

2. V-belts loose.

1. Pulley setscrews or keys are missing or

loose.

2. Motor fan is hitting the cover.

3. V-belts are defective.

1. Outfeed table is set too low

1. Outfeed table is set too high.

1. Knots or conflicting grain direction in

wood.

2. Dull knives.

3. Feeding too fast.

4. Taking too deep of a cut.

1. Wood may have high moisture content

or surface wetness.

2. Dull knives.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open connec-

tions.

1. Inspect cord or plug for damaged insulation and shorted wires.

2. Inspect all connections on motor for loose or shorted terminals

or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals or

worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

1. Feed workpiece slower.

2. Adjust V-belts. See page 38-39.

1. Inspect keys and setscrews. Replace or tighten if necessary.

2. Tighten fan or shim cover.

3. Replace V-belts. See page 39.

1. Align outfeed table with cutterhead knife at top dead center. See

page 22-23.

1. Align outfeed table with cutterhead knife at top dead center. See

page 22-23.

1. Inspect stock for knots and grain.

2. Inspect and sharpen cutterhead knives.

3. Slow down the rate that you feed the wood into the cutterhead.

4. Raise the infeed table to take a smaller depth of cut. Never

exceed

1

⁄8" per pass when edge jointing or

1

⁄32" when surface

planing. Reduce cutting depth for harder woods.

1. Check moisture content and allow to dry if moisture is too high.

2. Inspect and sharpen cutterhead knives.

TROUBLESHOOTING GUIDE

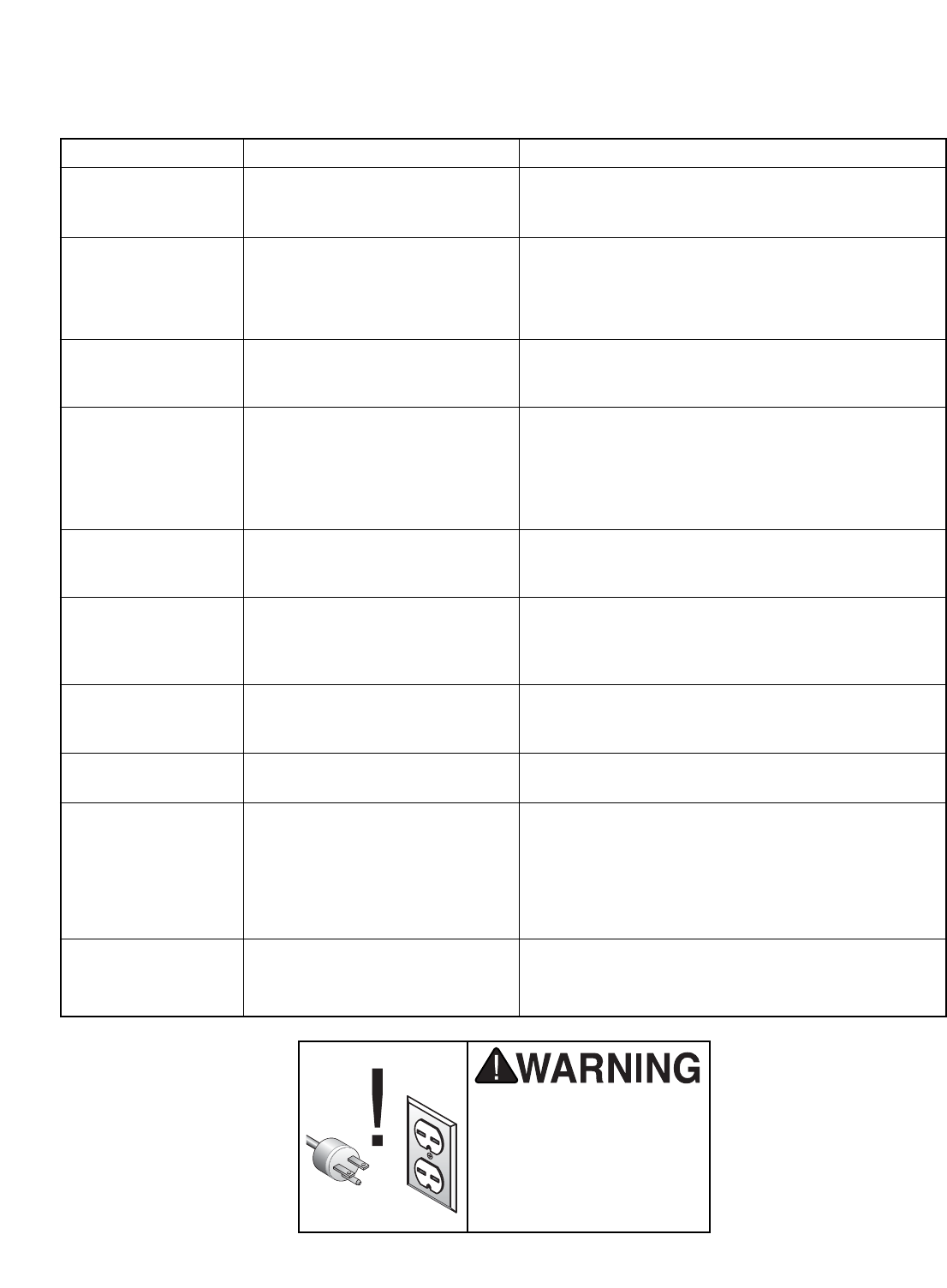

Disconnect power to the

machine when perform-

ing any maintenance or

repairs. Failure to do this

may result in serious

personal injury.