G0604 6" X 56" Jointer

-13-

Figure 4. Model G0604 overhead view

dimensions.

Machine Placement

Consider the jointer dimensions and size of mate-

rial to be processed through each machine, and

space for auxiliary stands, work tables or other

machinery when establishing a location for your

jointer. See Figure

4 for the Model G0604 over-

head view dimensions.

The unpainted cast iron surfaces are coated with

a waxy oil to protect them from corrosion during

shipment. Remove this protective coating with a

solvent cleaner or citrus-based degreaser such

as Grizzly’s G7895 Degreaser. To clean thor

-

oughly, some parts may need to be removed. For

optimum performance from your machine,

make sure you clean all moving parts or slid

-

ing contact surfaces that are coated. Avoid

chlorine-based solvents, such as acetone or

brake parts cleaner, as they may damage painted

surfaces should they come in contact.

Site Considerations

Cleanup

55

1

⁄2"

25"

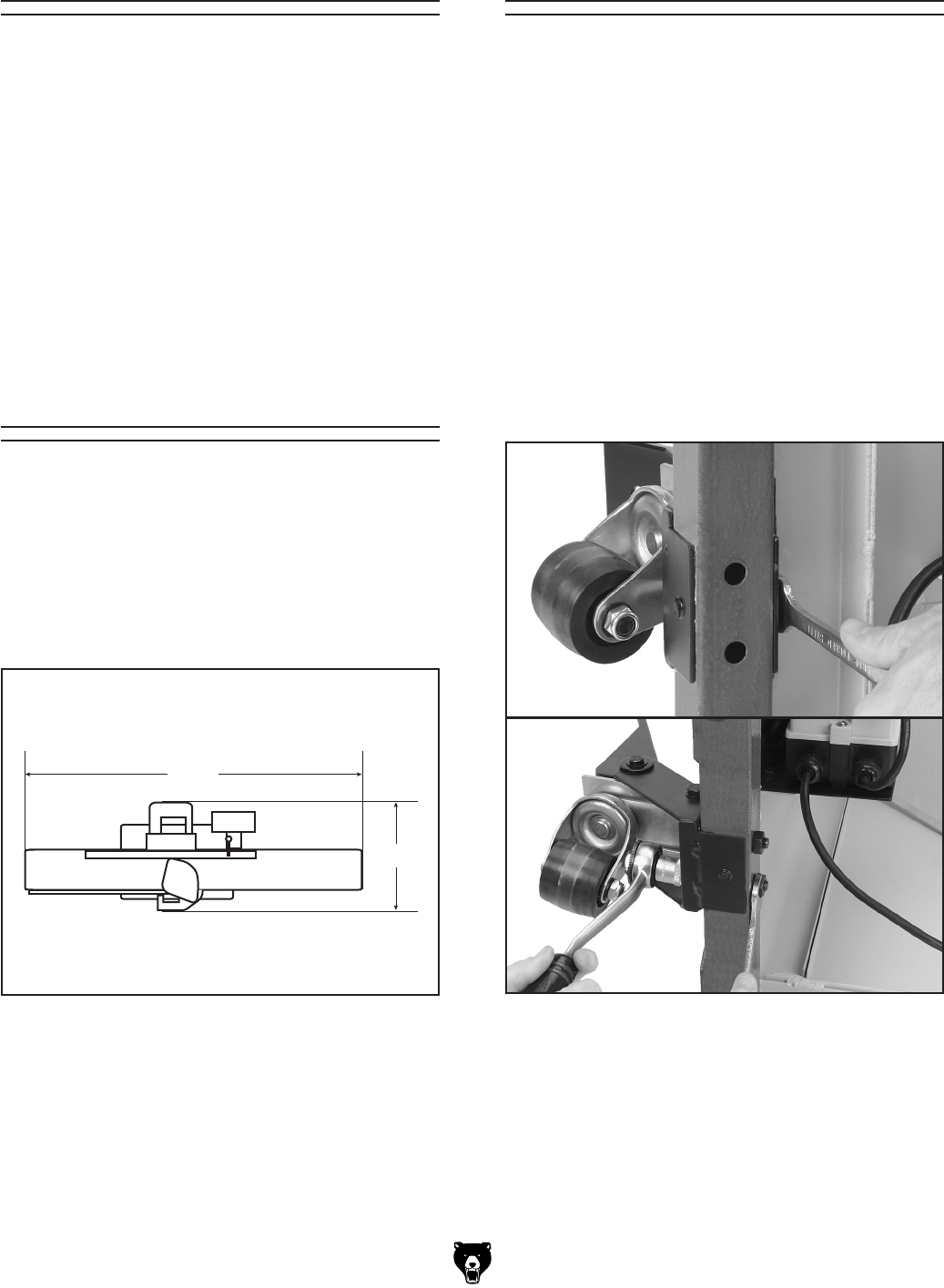

Components and Hardware Needed: Qty

Wheel Assembly ................................................

1

Stand Assembly w/Motor ...................................

1

Hex Bolt M8-1.25 x 50 .......................................

1

Flat Washer 8mm ..............................................

1

Hex Bolts M10-1.5 x 55 .....................................

2

Flat Washers 10mm ..........................................

2

Hex Nuts M10-1.5 .............................................

2

To attach

the wheel:

1. Carefully lay the stand on its side so you can

access the underside.

2. Bolt the wheel assembly to the stand with the

provided hardware as shown in Figure

5.

Wheel Assembly

Figure 5. Bolting the wheel assembly to the

stand.

3. Turn the stand rightside up.