G0604 6" X 56" Jointer

-37-

Adjusting Table Parallelism

For safe and proper cutting results, the tables

must be parallel to the cutterhead. Adjusting them

to be parallel is a task of precision and patience,

and may take up to one hour to complete. Luckily,

this is considered a permanent adjustment and

should not need to be repeated for the life of the

machine.

Due to the complex nature of this task, we rec

-

ommend that you double check the current table

positions to make sure that they really need to be

adjusted before starting. Refer to the previous two

subsections if you have not just completed them.

The tables have four eccentric bushings under

each corner that allow the tables to be adjusted

parallel. These eccentric bushings are locked in

place by piggybacked set screws (one on top of

the other) and adjust when unlocked and rotated.

The correct order for adjusting the table parallel

-

ism is to first adjust the outfeed table parallel with

the cutterhead, then adjust the infeed table paral

-

lel with the outfeed table.

When setting the outfeed table, all measurements

must be made from the cutterhead body—not the

knives—or results may get skewed the next time

you change knives.

IMPORTANT: The steps below are intended to

be performed in succession with the procedures

for checking the outfeed and infeed tables, begin

-

ning on

Page 36. DO NOT CONTINUE UNTIL

YOU HAVE FOLLOW

ED THOSE PROCEDURES

FIRST!

To adjust the table parallelism:

1. Place the straightedge on the outfeed table

so it hangs over the cutterhead, and lower

the outfeed table until the straightedge just

touches the cutterhead body, as shown in

Figure 52 (rotate the cutterhead if neces-

sary).

2. Remove the set screw from each of the four

eccentric bushings (

Figure 56) under the

outfeed table, and loosen the set screws

underneath those removed set screws.

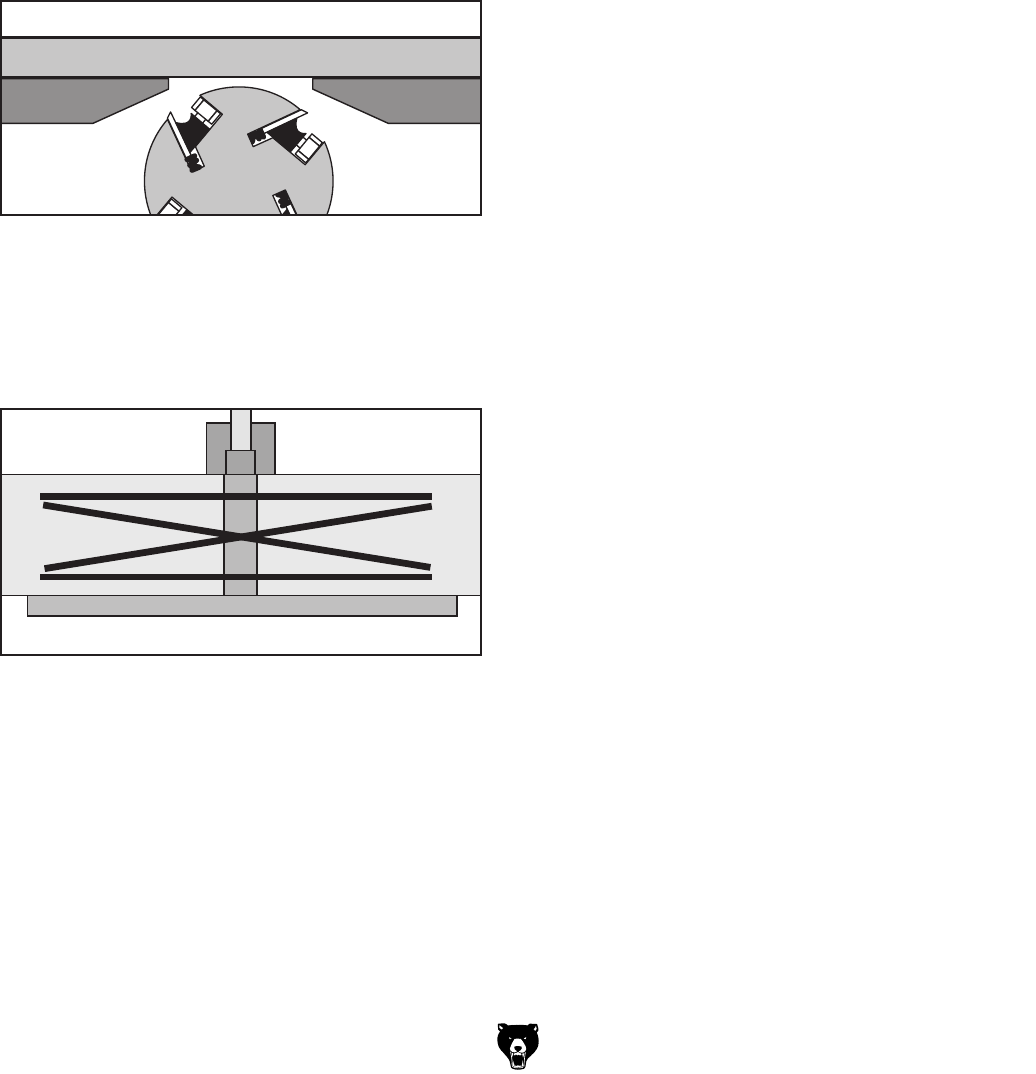

Checking Infeed Table

To check the infeed table parallelism:

1. Follow all the steps for checking the outfeed

table parallelism to first make sure that the

outfeed table is parallel with the cutterhead.

2. Raise the outfeed table higher than the

cutterhead.

3. Place the straightedge halfway across the

infeed table and halfway over the outfeed

table, and adjust the infeed table even with

the outfeed table, as shown in

Figure 54.

Figure 54. Infeed and outfeed tables set evenly.

4. Place the straightedge in the positions shown

in Figure 55. In each position, the straight-

edge should sit flat against both the outfeed

table and the infeed table.

—If the straightedge sits flat against both the

infeed and outfeed table, then the tables are

parallel. Set both table heights (

Pages 38

& 39) and replace the cutterhead guard.

—If the straightedge does not sit flat against

both the infeed and outfeed table in any

of the positions, then follow the

Adjusting

Table Parallelism instructions.

Figure 55. Straightedge positions for checking

infeed/outfeed table parallelism.