-1 0 -

-10-

B. POWER FEED

X. OPERATION

The bench-mounted Model G1126 Gear-Head Mill / Drill is a fundamental metalworking machine

capable of most standard milling and drilling operations. In order to effectively use the machine, it’s

necessary to understand the various adjustments the Model G1126 features. This section deals with

the specific adjustments required to operate the Model G1126.

A. TABLE

The Model G1126’s table rides on precision dovetail ways. Adjustment from side to side is accom-

plished by turning the handwheel at the end of the table, or by using the power feed. Movement from

front to back is controlled by the handwheel at the front of the machine’s base. The mill / drill’s tables

can be locked to eliminate unwanted movement in either direction by using the locking levers locat-

ed just below the table. The side-to-side locks are located on either side of the power feed

microswitch. The locks restricting movement from front to back are located on the drill / mill’s base,

just below the table. See Figure 6.

Figure 6

The table on your G1126 Gear-Head Mill / Drill is equipped with

1

/2" T-slots, which allow you to

mount fixtures, such as vises, rotary tables and dividing heads to your machine. The T-slots are

designed to accept

1

/2" T-bolts to anchor the optional equipment mentioned above. Keep in mind that

T-bolts are measured at the thread, not at the head, so you’ll want to use care when sizing T-bolts

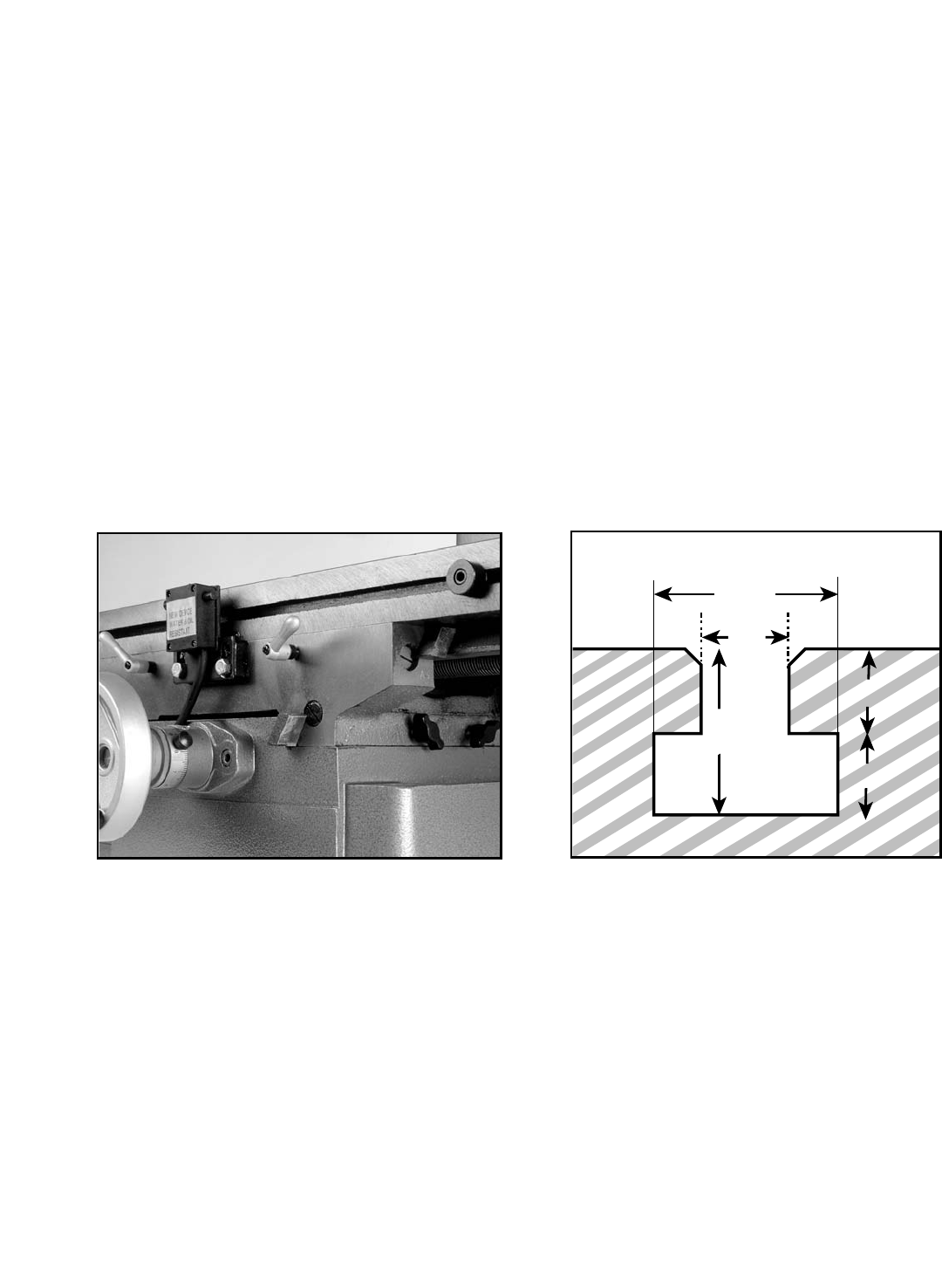

for use with the Model G1126. See Figure 7 for specific measurements.

Figure 7

1

1

/

16"

5

/8

"

7

/

16"

7

/

16"

7

/

8"

The power feed supplied with your Model G1126 features a variable speed control, which allows

you to adjust feed speed to fit specific materials you choose to mill. The power feed is activated by

a switch mounted on the outboard end of the power feed gearbox.

A microswitch mounted on the front of the table casting allows you to limit table travel and also func-

tions as an “auto pilot” for hands-free multiple passes.