-13-

Figure 11. Adjusting disc table stops.

G1183/1276 Combination Sander

6. Repeat this procedure with the 45° stop.

You’ll need a known 45° angle, such as a

speed square or the head of a combination

square to check accuracy.

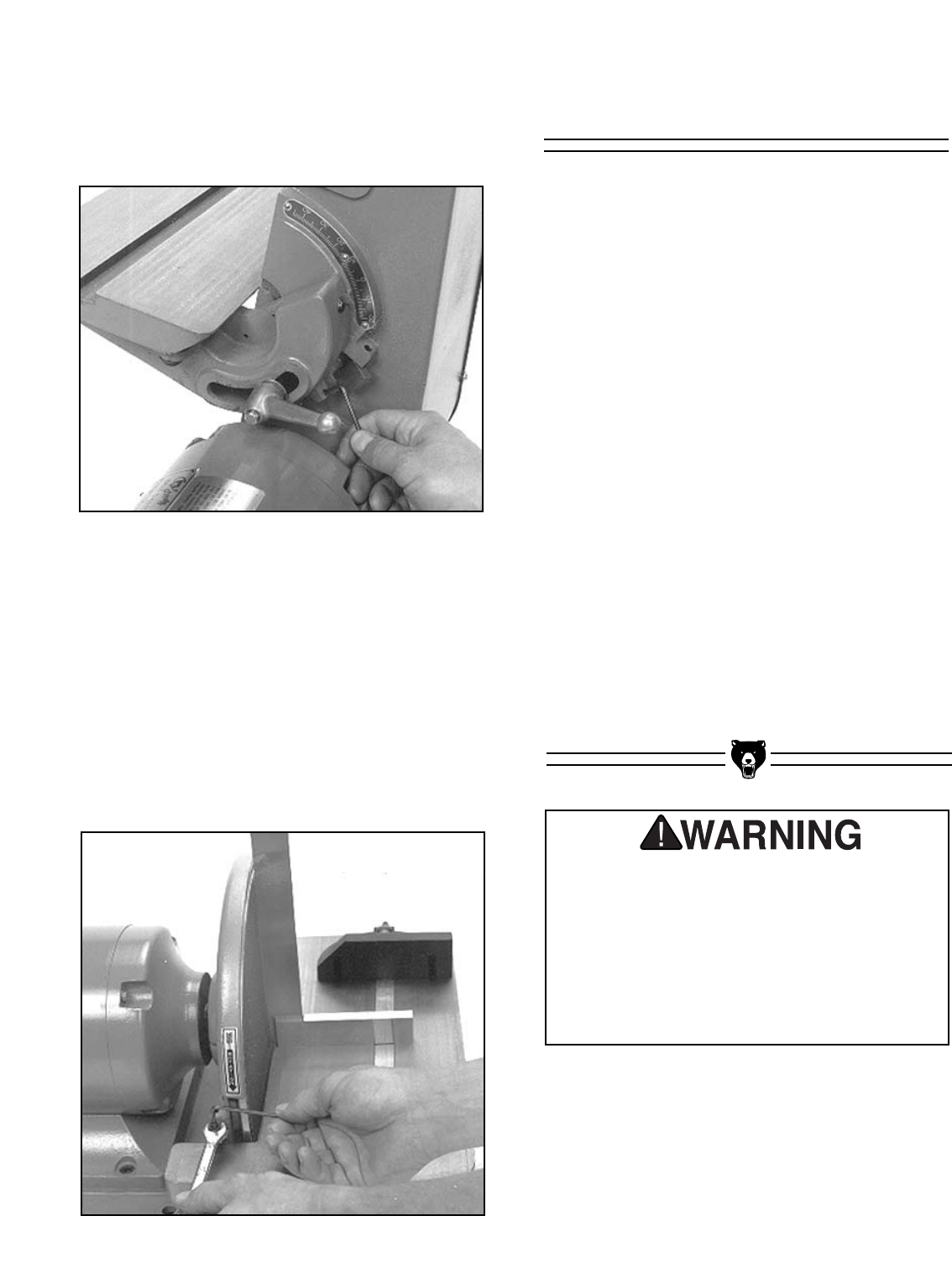

Figure 10. Adjusting belt table stops.

To Adjust the Disc Table Positive Stops:

1. Loosen both star knobs.

2. Flip block over table.

3. Loosen check nut.

4. Place accurate square on table and against

disc as shown in Figure 11.

5. Make fine adjustments by turning the

setscrew in or out. Secure the checknut.

Belt Platen

DO NOT attempt to operate this machine

before completing the assembly and adjust-

ment instructions. Be sure that the switch is

off and the cord is disconnected from the

power source at all times until assembly

and adjustment are complete and you have

reviewed all safety guidelines. Serious

injury could occur.

The belt platen should be adjusted out far enough

so it is flush with, or slightly higher than the upper

roller. The rollers are slightly crowned, that is they

are higher in the center than at the edges. This

crowning helps the belt to stay centralized on the

rollers. The adjustment of the platen to the roller

should be done at the high point, or center, of the

roller.

1. Loosen the cap screw on the side of the

belt housing with a 6mm Allen

®

wrench.

This frees the in and out movement of the

belt platen

2. Use a straightedge positioned in the center

of the platen which extends over the upper

roller. Adjust the belt platen in and out until

the straightedge is just barely lifted off of

the idler roller.

3. Tighten cap screw.

See the section on Belt Installation/Tracking for

more information on adjusting the rollers for prop-

er tracking.