-10- G4002/3 Gear Head Lathes

To remove a chuck:

1. Place a piece of plywood across the lathe

bed and position it just under the chuck.

The board should be at least 8" wide and

10" long.

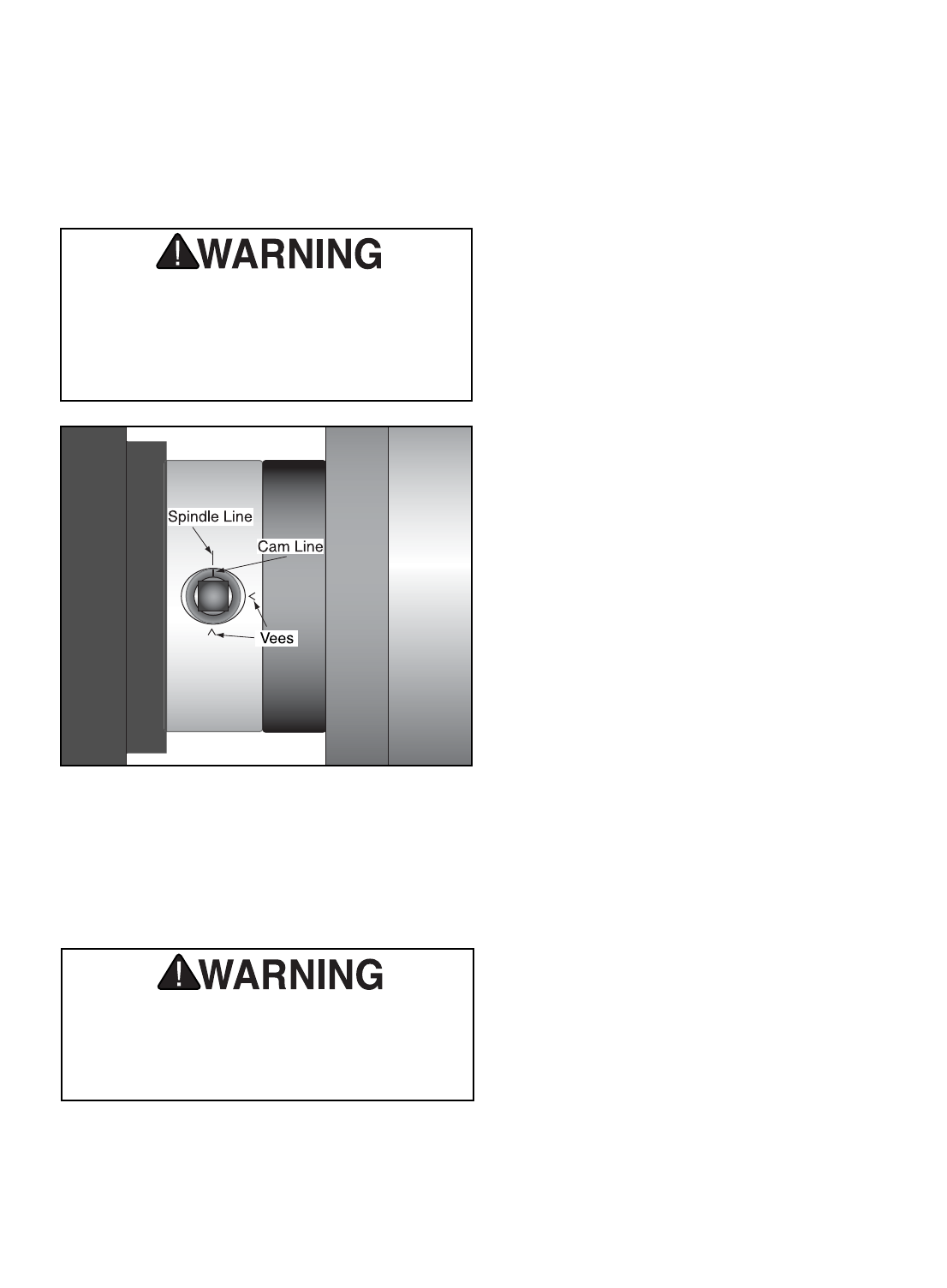

2. Turn a cam, with the chuck key, in the lathe

spindle in a counter-clockwise rotation until

the line on the cam is aligned with the line

going across the spindle housing as in

Figure 3.

Figure 3. Cam lines aligned to spindle line.

Never leave a chuck key in the chuck when

it is not in use. If the machine is acciden-

tally started with this in place, it can

become a projectile and cause serious

injury.

The chuck is heavy and can be awkward to

handle. Be aware that when removing or

installing a chuck a finger pinch situation

exists.

3. Turn the other cams in the same way. Make

sure to support the chuck with one hand as

you align the last cam. The chuck may

come off at this point so it is important you

are ready to support its weight.

4. Remove the chuck key.

If the chuck is still tight on the spindle:

Tap the back of the chuck with a rubber or wood-

en mallet while supporting the bottom of the

chuck with your free hand. If the chuck does not

immediately come off, rotate the spindle approxi-

mately 60˚ and tap again. Make sure all the

marks on the cams and spindle are in proper

alignment.

To install a chuck:

1. Place a piece of plywood across the lathe

bed and position it just under the spindle.

2. Lift the chuck up to the spindle and align

the pins in the back with the holes on the

spindle’s face and insert the pins.

3. While supporting the weight of the chuck,

turn one cam with the chuck key until the

cam line is between the two vees on the

spindle. Do not tighten at this time.

4. Rotate the spindle and repeat step 3 on the

last two cams.

5. Return to the first cam and snug it up.

Repeat with the rest of the cams.

6. Finally, tighten all three cams.