G4002/3 Gear Head Lathes -23-

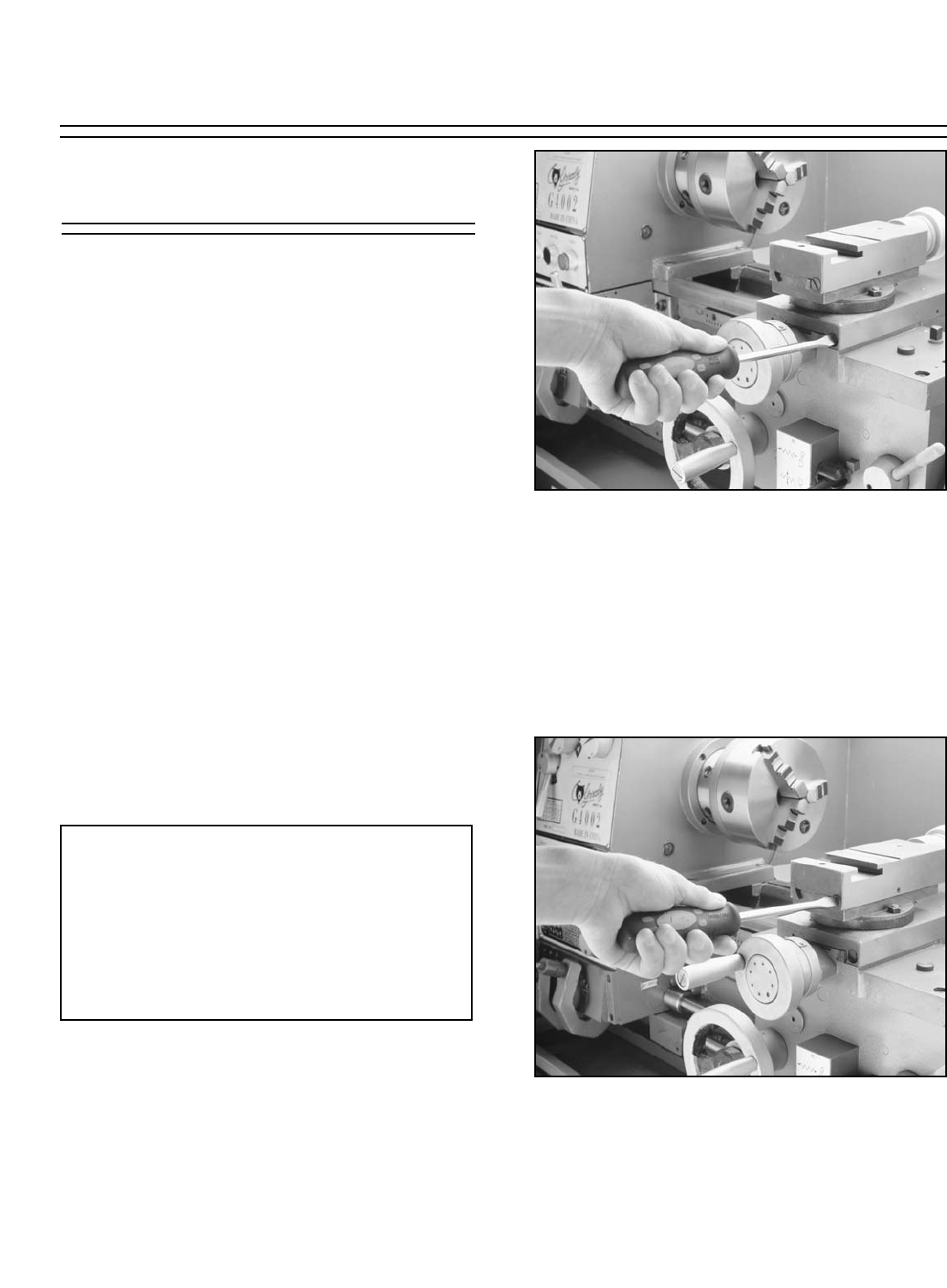

Compound Gib - The gib on the compound is

adjusted by the same method as the gibs on the

cross-slide, except the screw closest to the oper-

ator (when the compound slide is aligned with the

cross slide) must be loosened and the screw fur-

thest from the operator tightened to make the gib

tighter. See Figure 26.

Figure 26. Tightening this screw tightens gib.

NOTICE

When adjusting gibs, keep in mind that the

goal of gib adjustment is to remove unneces-

sary sloppiness from the slide’s movement

without causing them to bind. Loose gibs may

cause poor finishes on the workpiece. Over

tightening may cause premature wear.

SECTION 6: ADJUSTMENTS

Figure 25.Adjusting the cross-slide gib.

There are three main gib adjustments for the

Model G4002/3. They are: the cross-slide gib, the

compound slide gib and the saddle gib.

Cross-slide Gib - The gib on the cross-slide is

adjusted by the two screws located at each end.

See Figure 25. To adjust, loosen the setscrew

located along the edge of the cross-slide.

This setscrew is provided for locking the slide for

certain operations. After making the adjustments

detailed below, tighten the setscrew until it just

touches the gib.

The gib is wedge shaped and by loosening the

screw closest to the operator and then tightening

the opposite screw, the slide will become looser.

Conversely, loosening the screw furthest away

from the operator and tightening the closer screw

will tighten the gib. Do not over tighten. Adjust the

gib so that it creates a slight drag when the slide

is in motion. Test the ease of motion with the gib

slightly loose. Begin tightening the gib and test

after making small adjustments. When a slight

drag is detected the gib is properly adjusted.

Gibs