Quick Change Selection

The two levers at the bottom of the headstock

change the feed rate, or the number of threads-

per-inch. This section of the machine is com-

monly known as the Quick Change Gear Box.

See Figure 11. The left-hand lever can be

engaged in any of five different positions and are

listed on the charts as A, B, C, D, and E. The

right-hand lever has 8 positions and are listed on

the charts as 1 through 8.

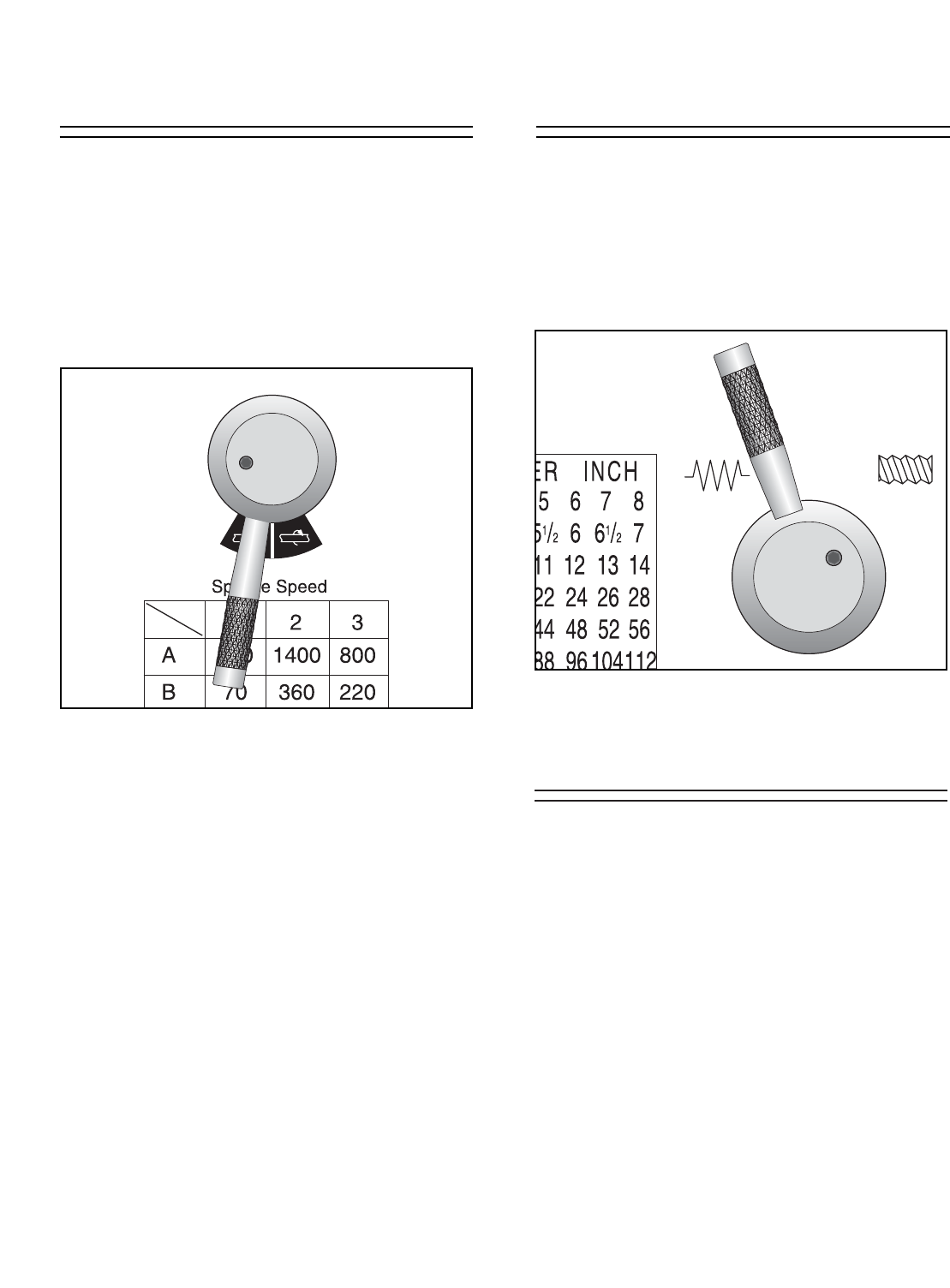

The machine label describes some of the more

typical settings which might be used. Figure 12

shows the feed rate chart located on the gear

cover of the lathe. The chart is divided into met-

ric feed rates and inch feed rates.

-14- G4002/3 Gear Head Lathes

Figure 9. Directional control lever.

Feed Direction

Selecting the Feed Rod

Never move selection levers while machine is

running.

The G4002/3 Metal Lathe can cut left or right while

feeding or threading and across both ways for fac-

ing operations. This feed direction is controlled by

the selection knob as shown in Figure 9.

When the selection knob is positioned as depict-

ed in Figure 9, the apron will move to the right

along the bed or the cross feed will travel away

from the operator. The cross feed and longitudi-

nal feed selection is controlled on the apron and

will be discussed later.

To reverse the direction of the feeding or thread-

ing operation, rotate the selection knob to the

right. It should be noted that when the lever is

positioned in the middle, no direction is selected

and all of the drive mechanisms after this point

are in neutral.

Important:

Do not force any selection lever on the machine.

If the lever will not engage, rotate the chuck by

hand while keeping light pressure on the selec-

tor. As the chuck rotates it aligns the gears and

the selector will engage.

Figure 10. Feed rod selected.

The feed rod can be selected by rotating the han-

dle to the left as in Figure 10. Use this position for

all feeding operations. When the lever is posi-

tioned straight up, no drive device is selected and

the gear train is in neutral after this point.