-20- G4002/3 Gear Head Lathes

Figure 21. Spindle rotation control lever.

Spindle rotation control - The spindle rotation is

controlled from the lever on the right hand side of

the carriage. Moving the lever down causes the

spindle to rotate counter clockwise. Moving the

lever up causes the spindle to turn clockwise. The

middle position stops the motor and the lever is

considered to be in a neutral position. See Figure

21.

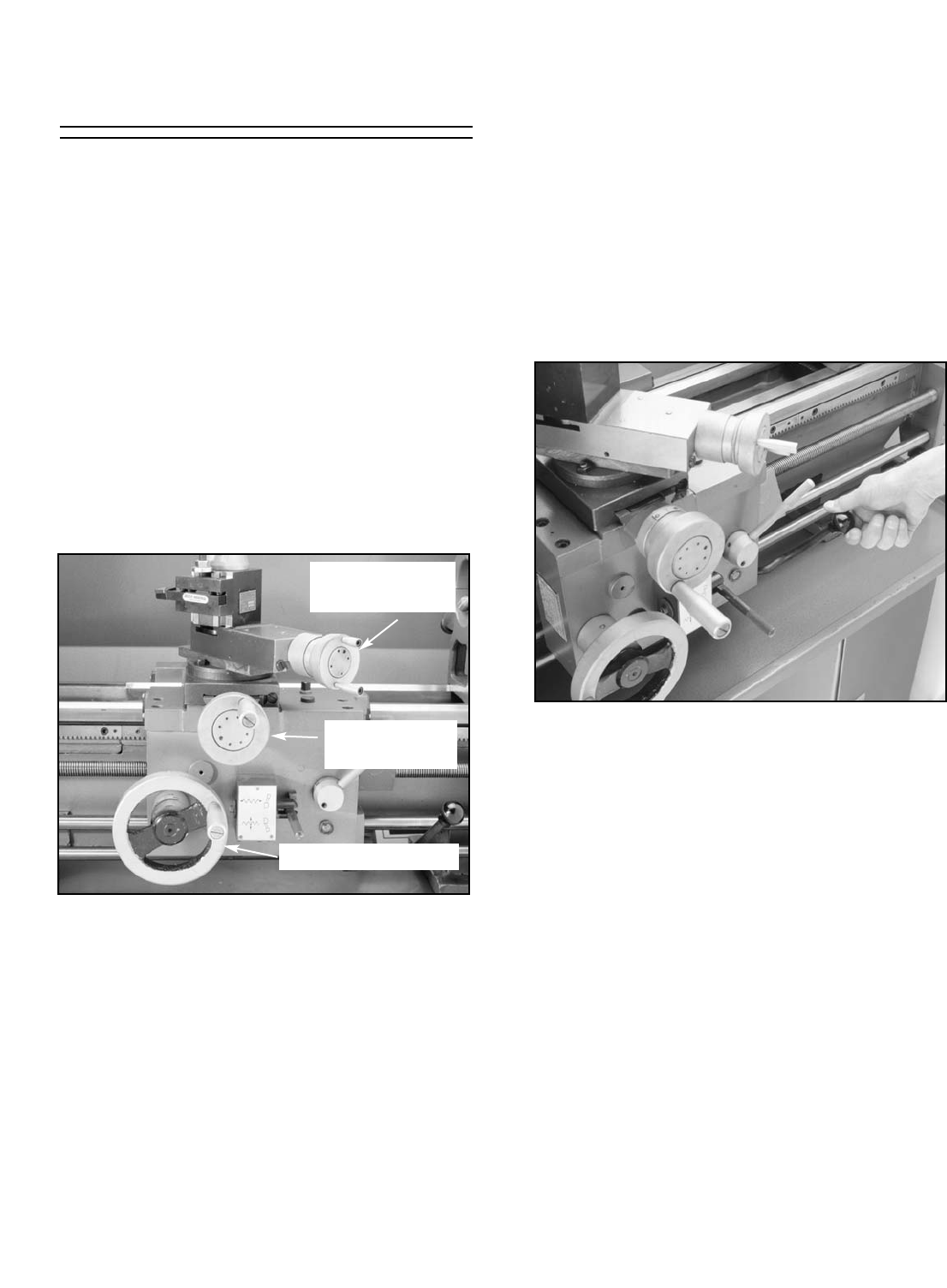

Figure 20. Handwheel locations.

Carriage Controls

The carriage handwheel allows the cutting tool to

move along the length of the lathe bed. The

cross slide allows the cutting tool to travel per-

pendicular to the bed. The carriage features a top

slide which allows linear movement of the cutting

tool at any preset angle. This section will review

the individual controls on the carriage and pro-

vide descriptions of their uses. See Figure 20.

Compound Slide Handwheel - The Top Slide

Handwheel controls the position of the cutting

tool relative to the workpiece. The top slide is

adjustable for any angle. The graduated dial is

adjustable using the same method as the dial on

the cross slide. Angle adjustment is controlled by

hex nuts on the base of the top slide.

Cross Slide Handwheel - The Cross Slide

Handwheel moves the top slide toward and away

from the work. Turning the dial clockwise moves

the slide toward the workpiece. The graduated

dial can be adjusted by holding the handwheel

with one hand and turning the dial with the other.

Carriage Handwheel - The Longitudinal

Handwheel moves the carriage left or right along

the bed. The control is helpful when setting up the

machine for turning or when manual movement is

desired during turning operations.

Carriage Handwheel

Cross Slide

Handwheel

Compound Slide

Handwheel