-20- G8622 Tilting Spindle Sliding Table Shaper

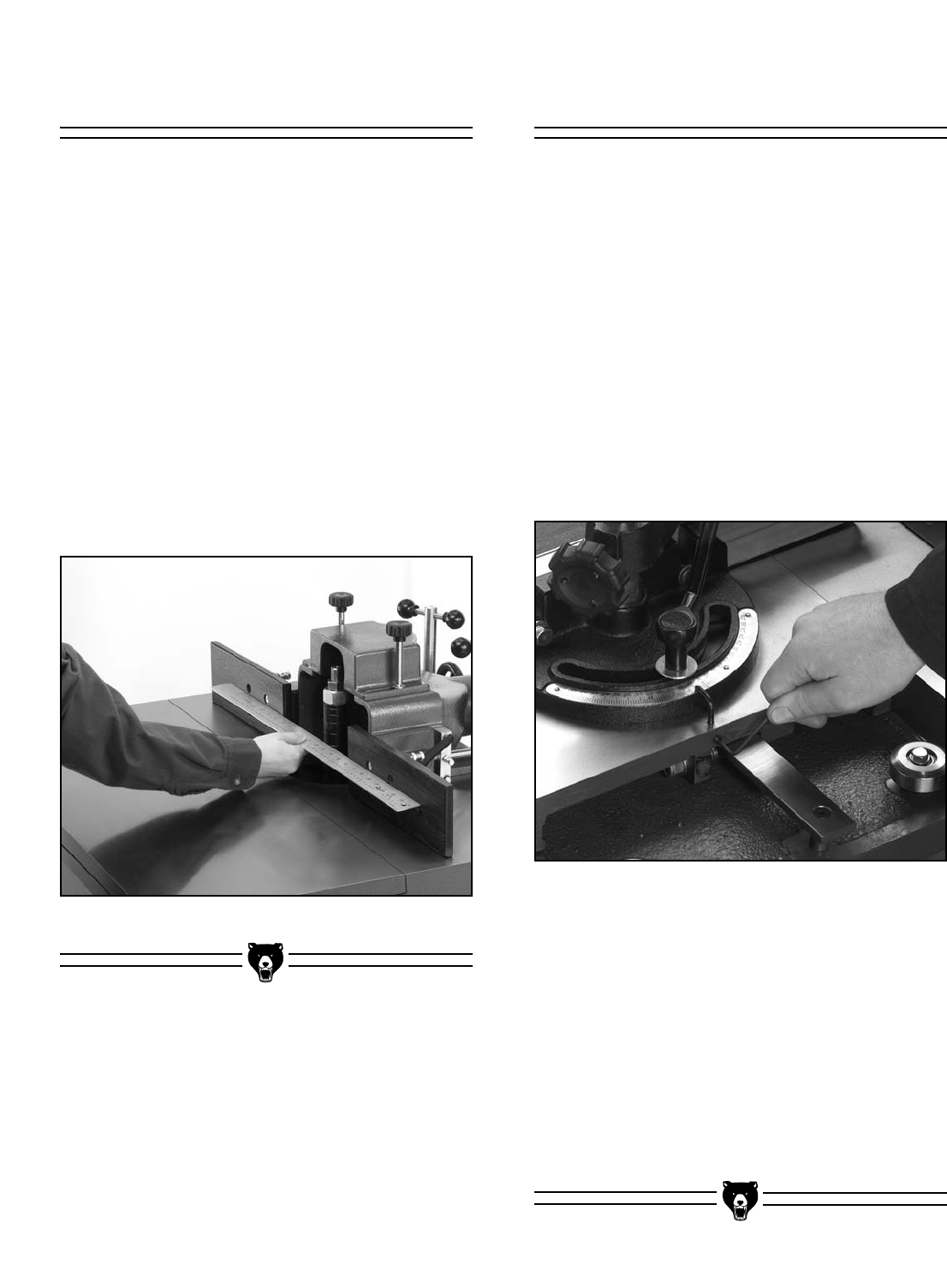

Figure 29. Setting the miter gauge pointer.

Setting Miter Gauge

You will need to square the miter gauge each

time it is removed from the table. To do this:

1. Ensure that the fence halves are aligned and

that the miter assembly is correctly assem-

bled.

2. Place one end of a framing or try square

flush with the infeed shaper fence.

3. Rotate the miter gauge/fence so that it lines

up flush with the other end of the square.

4. Set the miter gauge pointer to 0° and tighten

the setscrew as shown in Figure 29.

5. Keeping the square flush with the infeed

fence and the miter fence, clamp it to the

table, and slide the table across the shaper.

The square should stay flush with both

infeed and outfeed fences during this move-

ment. If this is the case, proceed to the next

section. If they do not stay flush or are not

square to the miter fence, repeat steps 1-4

until they are true. During operation, move

the infeed and outfeed fences away from the

workpiece before cutting.

Figure 28. Aligning fences with straightedge.

Aligning The Fences

The following procedure ensures that the fence is

parallel with itself and square to the table.

1. Check that the bolts through the wood facing

are tight on each side and are adequately

countersunk.

2. To align the wood facing, adjust one or both

fence halves so they are in close alignment.

Micro-adjust and check the alignment with a

straightedge as shown in Figure 28.

3. If the wood fences cannot be made parallel

by adjusting the fence controls, shim the

incorrect fence with electrical washers.

Normal washers may work, but electrical

washers allow for fine adjustments.