G8622 Tilting Spindle Sliding Table Shaper -27-

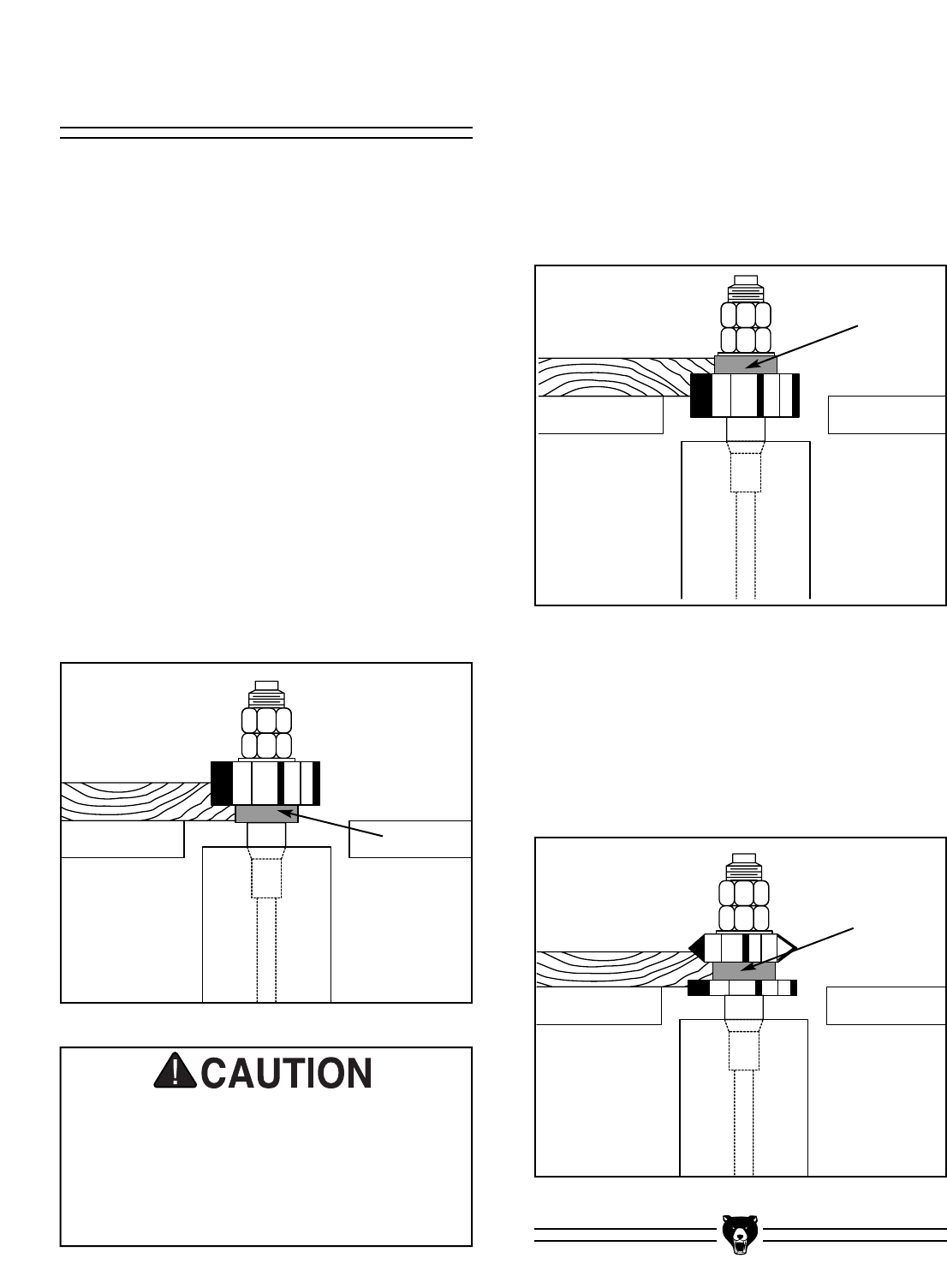

Figure 41. Rub collar installed above cutter.

Figure 42. Rub collar between two cutters.

3. Between two cutters: Using a rub collar

between two cutters, as in Figure 42, has

the distinct advantage of performing two cuts

at once or eliminating the need to change

cutters for two different operations. Notice

that part of the edge is left uncut. The uncut

portion rides on the rub collar.

2. Above the cutter: When the rub collar is

used above the cutter as seen in Figure 41,

the cut cannot be seen. This offers some

advantage: the stock is not affected by slight

variations in thickness and accidental lifting

will not damage the workpiece. If lifting

occurs, simply correct the mistake by repeat-

ing the operation.

Figure 40. Rub collar installed below cutter.

Rub Collars

Rub collars are used when shaping curved or

irregular workpieces, such as arched doors or

round table tops. Rub collars also limit the depth

of your cut.

There are two types of rub collars—solid and ball-

bearing. We recommend against the use of solid

rub collars. Grizzly carries an extensive line of

ball bearing rub collars designed for use with

Grizzly shapers. See the current catalog for list-

ings.

Rub collars may be used in any of the following

positions:

1. Rub collar below the cutter: When the rub

collar is used below the cutter as shown in

Figure 40, the progress of the cut can be

observed. However, any unintentional move-

ment may lift the workpiece into the cutter,

damaging your work and creating a potential

kickback situation.

Whenever the cutterhead is above the

workpiece, or you can see it spinning dur-

ing use, you must take extreme caution to

keep your hands away from the cutterhead.

Failure to do so may cause serious per-

sonal injury.