G9744Z Metal Cutting Bandsaw

-31-

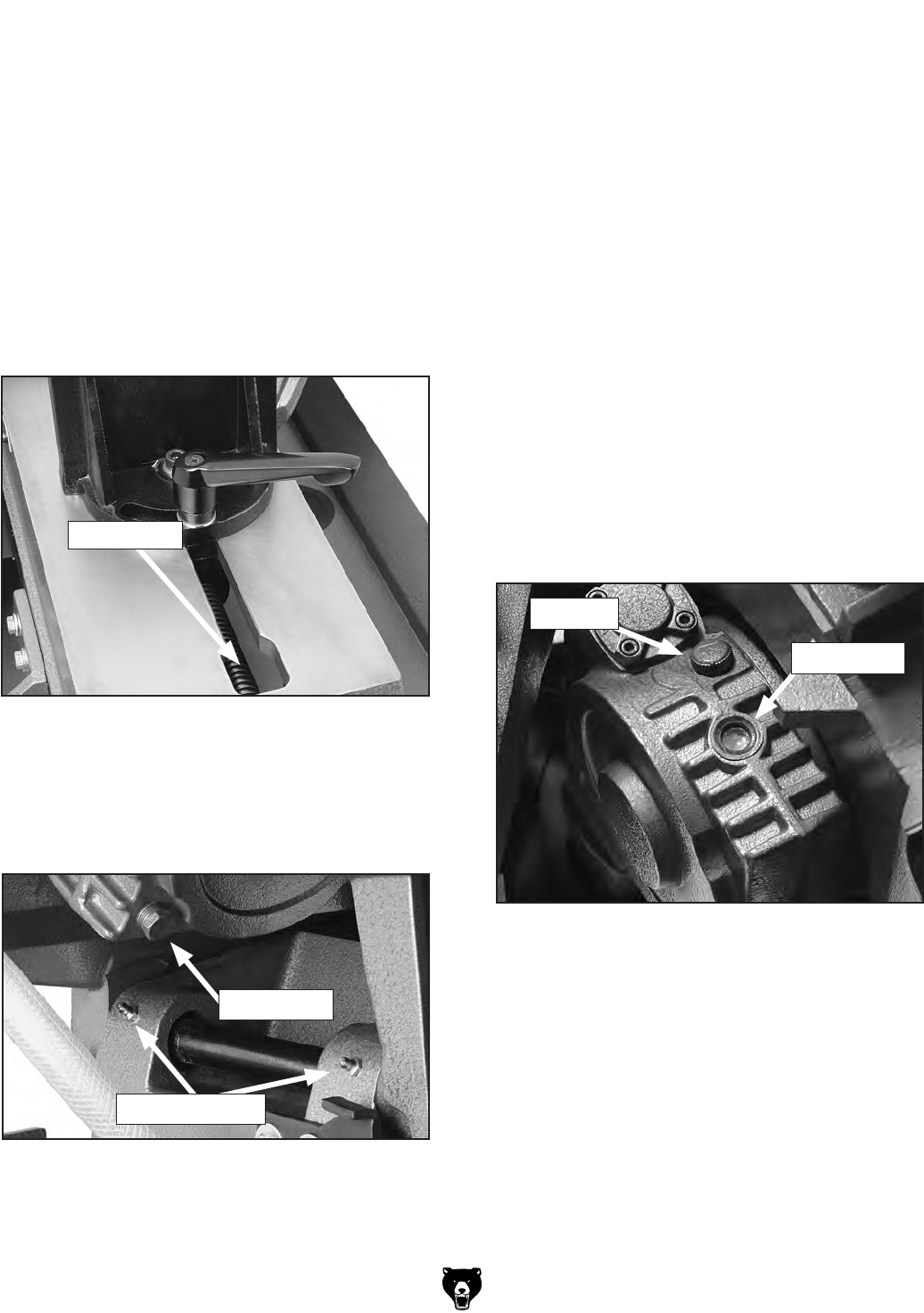

• Blade and Guides: Drop a few drops of

light machine oil on the blade and the blade

guides daily, especially when cutting cast

iron,

as no cutting fluid is recommended (see

Figure 33).

• Table

and Machined Surfaces: Tables can

be kept rust-free with regular applications of

products like SLIPIT®. For long term stor-

age

you may want to consider products like

Boeshield T-9™.

• Vise

Leadscrew: Place a few drops of light

machine oil on the vise leadscrew weekly

(see Figure 34).

Figure 36. Gear box.

Figure 35. Lubrication points.

Grease Fittings

Fill Cap

Sight Glass

Figure 34. Vise leadscrew lubrication area.

Leadscrew

• Grease Fittings on Pivot Point: Grease

these with general purpose grease as needed

to keep the pivot moving freely (see Figure

35).

T

he gearbox should be drained and refilled after

the first 50 hours of use and then once every year.

Use a high quality, ISO 68 or SAE 90 gear oil.

To change the gear oil:

1. Run

the bandsaw for a couple of minutes to

warm up the oil in the gearbox.

2. UNPLUG THE BANDSAW!

3. Raise

the bow to the highest angle and close

the feed control knob to lock the bow in posi-

tion.

4. Drain the gearbox by removing the drain plug

shown

in Figure 35.

5. Replace

the drain plug, then lower the bow to

its lowest position.

6. Open

the fill cap and fill the gearbox with oil

until you see the oil level reach the halfway

point in the sight glass (see Figure 36).

7. Tighten

the fill plug, connect the machine to

power and run the saw for a minute or two,

then check the oil level. Add more oil if need-

ed

to maintain the level at the halfway mark

in the sight glass.

Drain Plug