G9744Z Metal Cutting Bandsaw

-35-

Note: It is sometimes possible to flip the

blade inside out, in which case the blade will

be installed in the wrong direction. Check to

make sure the blade teeth are facing toward

the workpiece, as shown in Figure 40, after

mounting

on the bandsaw. Some blades will

have a directional arrow as a guide.

8. Apply a light amount of tension to hold the

blade

in place. Work your way around the

blade to adjust the position so the back of the

blade is against the flange of the wheels.

9. Complete

the blade change by following the

steps in Blade Tension & Tracking.

Figure 40. Blade cutting direction.

Blade Tension &

Tracking

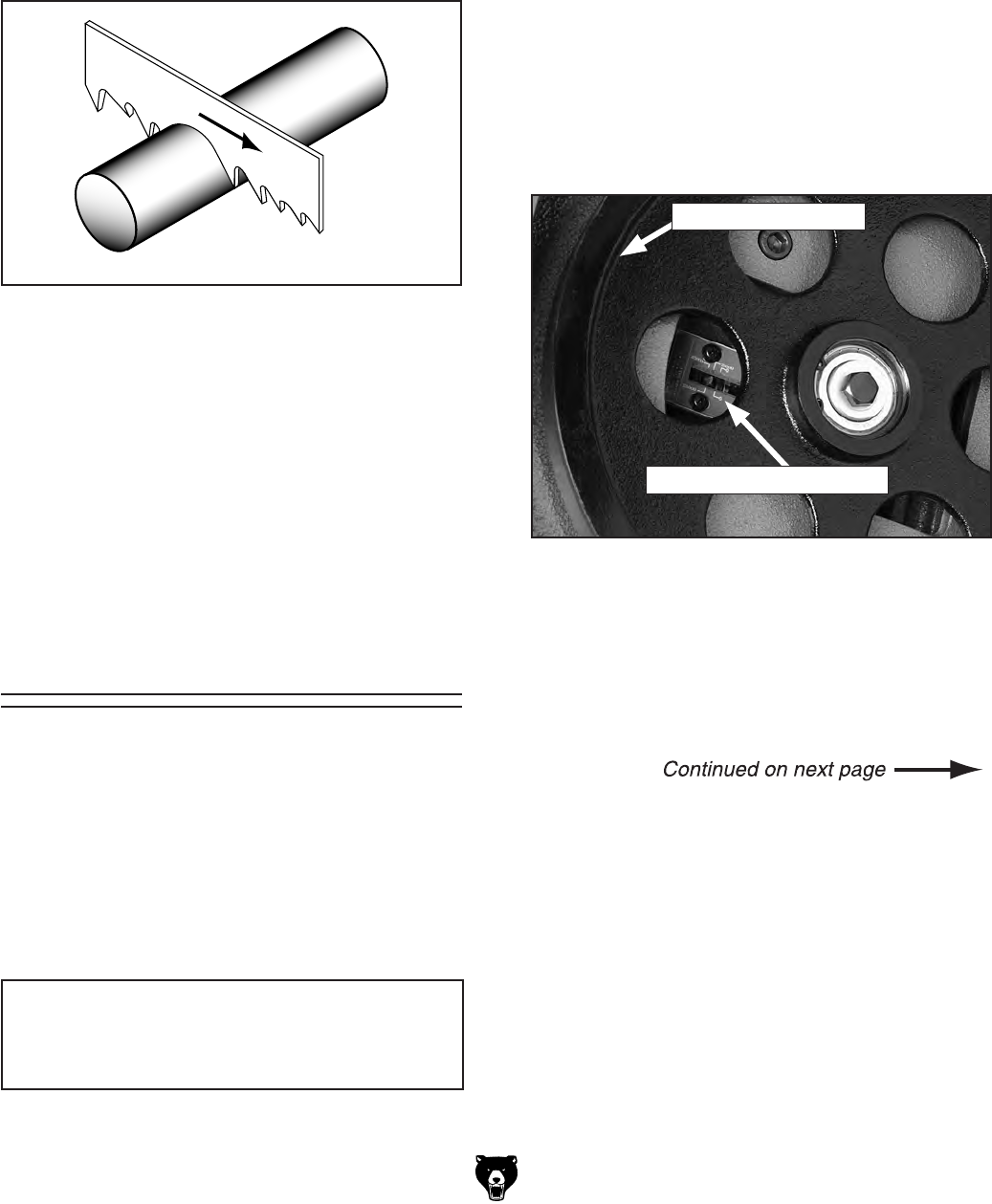

Figure 41. Blade tension indicator.

Blade Tension Indicator

NOTICE

Loosen blade tension at the end of each day

to prolong blade life.

To tension the blade on the bandsaw:

1. Turn

the blade tension handle clockwise to

tension the blade.

2.

Use the graduated

scale on the blade tension

indicator (Figure 41) to

determine blade ten-

sion in PSI.

—For carbon blades,

the blade tension should

be 20,000

PSI.

—For bi-metal blades, like the one supplied

with your machine, the blade should be

tensioned from 30,000 to 35,000 PSI.

Proper blade tension is essential to long blade

l

ife, straight cuts, and efficient cutting. The Model

G9744Z features a blade tension indicator to

assist you with blade tensioning.

Two major signs that you do not have proper

blade tension are: 1) the blade stalls in the cut and

slips on the wheels, and 2) the blade frequently

breaks from being too tight.

Tracking Set Screw

3. To fine tune blade tension, use a blade

tensioning gauge, like the one found in

SECTION 5: ACCESSORIES on Page 28.

Please

follow the instructions included with

your gauge and the blade manufacturer's

recommendations

on blade tension.