G9744Z Metal Cutting Bandsaw

-33-

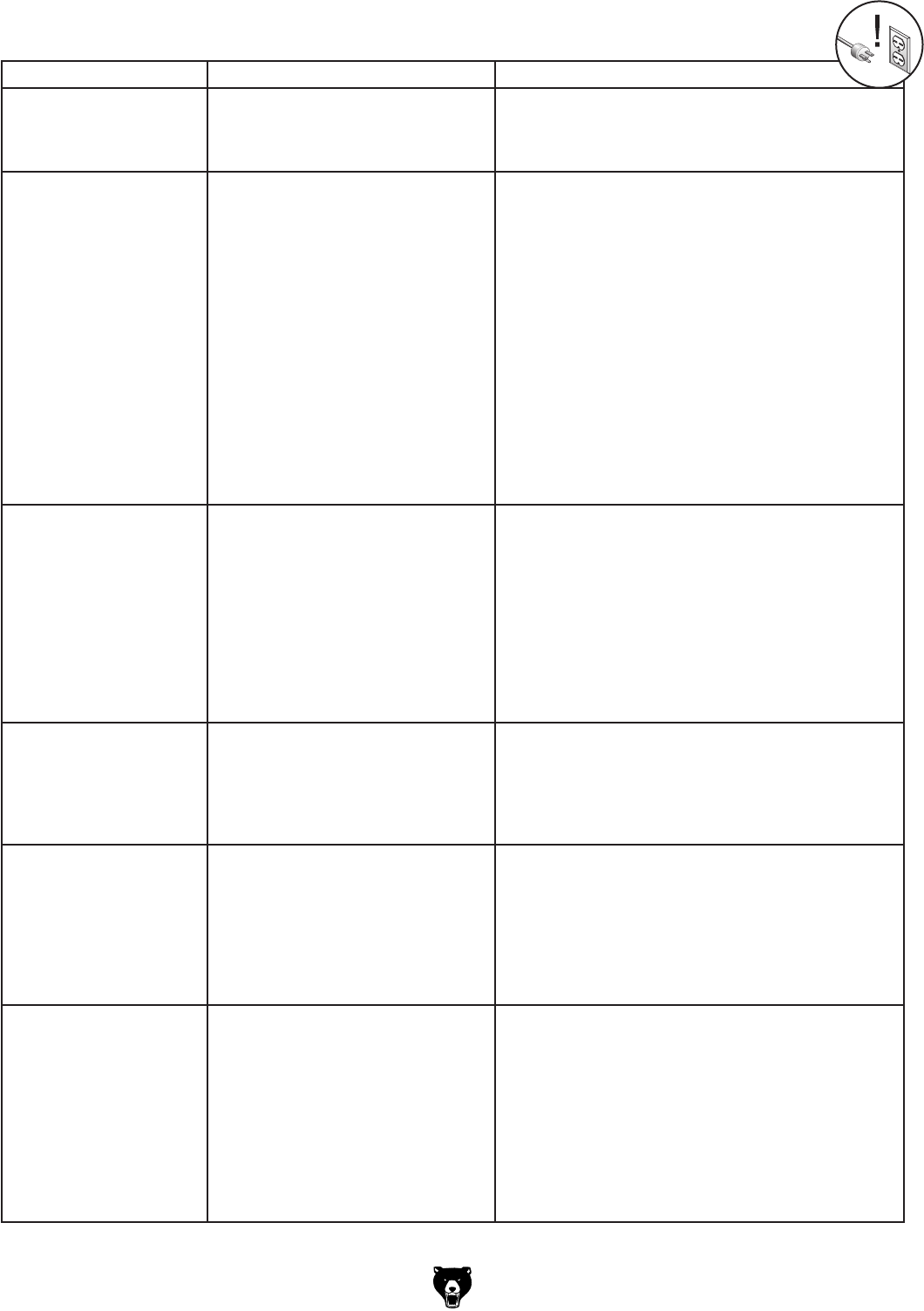

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Machine is loud when

cutting or bogs down in

the cut.

1. Excessive feed rate.

2. T

he blade TPI is too great, or the

material is too coarse.

1. Refer to Feed Rate on Page 24, or Blade Speed

o

n Page 24 and adjust as required.

2. Re

fer to Blade Selection on Page 23 and adjust as

required.

Blades break often. 1. Blade is not tensioned correctly.

2. T

he workpiece is loose in the vise.

3. T

he feed or cut speed is wrong.

4. T

he blade TPI is too great, or the

material is too coarse.

5. T

he blade is rubbing on the wheel

flange.

6. T

he bandsaw is being started with

the blade resting on the workpiece.

7. T

he guide bearings are

misaligned, too tight, or the blade

is rubbing on the wheel flange.

8. T

he blade is too thick, or the

blades are of low quality.

1. Check to see that blade is not excessively tight or

too loose.

2. C

lamp the workpiece tighter, or use a jig to hold the

workpiece.

3. Re

fer to Feed Rate on Page 24, or Blade Speed

on Page 24 and adjust as required.

4. Re

fer to Blade Selection on Page 23, and adjust

as required.

5. Re

fer to Blade Tracking on Page 36, and adjust as

required.

6. S

tart bandsaw and then slowly lower the headstock

by setting the feed rate.

7. Re

fer to Blade Tracking on Page 36, or Blade

Guide Arms on Page 22, and adjust as required.

8. U

se a higher quality blade.

Blade dulls prematurely. 1. T

he cutting speed is too fast.

2. T

he blade TPI is too coarse.

3. T

he blade feed pressure is too

light.

4. T

he workpiece has hard spots,

welds, or scale is on the material.

5. T

he blade is twisted.

6. T

he blade is slipping on the

wheels.

1. Re

fer to Blade Speed on Page 24 and adjust as

required.

2. Re

fer to Blade Selection on Page 23, and adjust

as required.

3. Re

fer to Feed Rate on Page 24, and adjust as

required.

4. I

ncrease the feed pressure, and reduce the cutting

speed.

5. Re

place the blade.

6. Re

fer to Blade Tension on Page 35, and adjust as

required.

Blade wears on one side. 1. T

he blade guides are worn or mis-

adjusted.

2. T

he blade guide slide bracket is

loose.

3. T

he wheels are out of alignment.

1. Re

fer to Blade Guides on Page 22 and replace or

adjust.

2. T

ighten the blade guide bracket.

3. Re

fer to Blade Tracking on Page 36, and adjust as

required.

Teeth are ripping from the

blade.

1. The

feed pressure is too heavy

and the blade speed is too slow; or

the blade TPI is too coarse for the

workpiece.

2. The

workpiece is vibrating in the

vise.

3. The

blade gullets are loading up

with chips.

1. Re

fer to Blade Selection on Page 23 and decrease

the feed pressure. Refer to Feed Rate on Page 24,

a

nd adjust as required.

2. Re

-clamp the workpiece in the vise, and use a jig if

required.

3. U

se a coarser-tooth blade.

The cuts are crooked. 1. T

he feed pressure is too high.

2. T

he guide bearings are out of

adjustment, or too far away from

the workpiece.

3. T

he blade tension is low.

4. T

he blade is dull.

5. T

he blade speed is wrong.

1. Re

fer to Feed Rate on Page 24, and adjust as

required.

2. Re

fer to Blade Guides on Page 22 and replace or

adjust.

3. Re

fer to Blade Tension on Page 35, and adjust as

required.

4. Re

fer to Blade Change on Page 34 and replace

the blade.

5. Re

fer to Blade Speed on Page 24 and adjust as

required.

Bandsaw Operations