-36-

G9744Z Metal Cutting Bandsaw

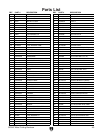

Blade Guide

Bearings

The blade tracking has been properly set at

the factory. The tracking will rarely need to be

adjusted if the bandsaw is used properly.

To adjust the blade tracking on the bandsaw:

1. Loosen or tighten the tracking set screw in

Figure 42 until the blade is tracking properly.

The blade

is tracking properly when the back

of the blade is lightly touching the flange of

both wheels.

Figure 42. Tracking set screw.

Tracking Set Screw

2. Remove the V-belt from the motor pulley and

spin either wheel by hand to observe how the

blade is tracking. Make sure the blade teeth

are not cutting into any part of the saw. Adjust

as needed.

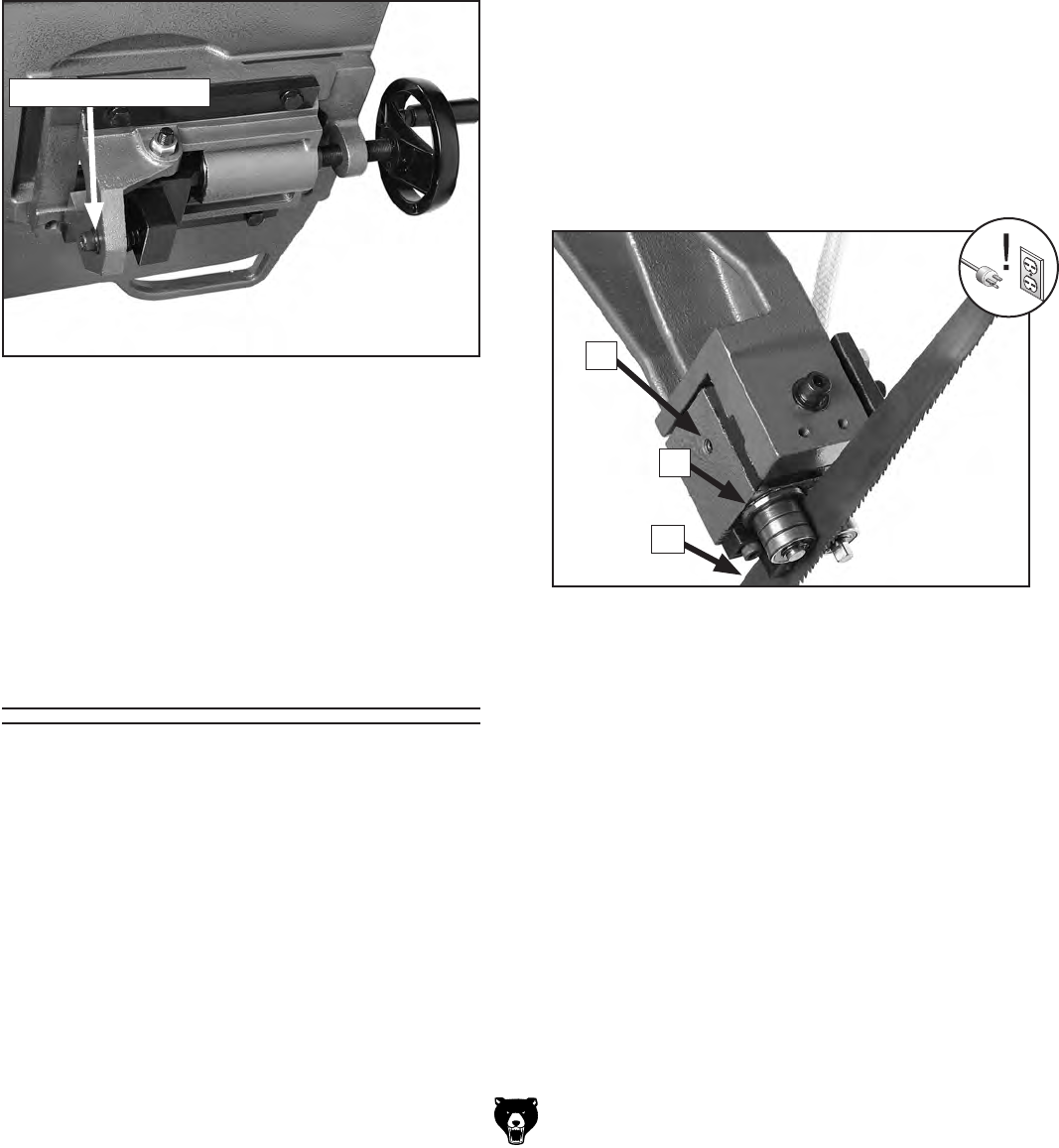

Figure 43. Blade guide adjustments.

A

B

C

The blade guide bearings are adjusted at the fac-

tory but due to shipping and storage may need

adjustment. Use Figures 43 & 44 t

o guide you

through the following steps.

To adjust the blade guide bearings:

1. Before

making adjustments, make sure the

blade is tensioned and tracking correctly.

2. UNPLUG THE BANDSAW!

3. Raise the bow high enough to give you room

to

work, then lock in place.

4. Remove both blade guards.

5. The back

of the blade (A) in Figure 43 should

make light contact with the backing bearing

(C).

—If

it does not, loosen the set screw (B)

shown in Figure 43, and move the bearing

(C)

up or down until it lightly touches the

back of the blade.

The blade guide roller bearings also need to be

adjusted. The front bearing is mounted on an

eccentric and can be easily adjusted to suit the

blade thickness.

To adjust the blade guide roller bearings:

1. Loosen

the set screw shown in Figure 44 to

allow the eccentric bushing to turn.