-16-

H7583 Tenoning Jig

MAKE SURE the blade clearance is adjusted

correctly! DO NOT adjust the work support

plate any closer than

1

⁄8" from the saw blade.

If the blade contacts the work support plate,

severe injury may occur. If the blade must

be closer than

1

⁄8" for special circumstances,

fasten a block of wood through the holes in

the work support plate to prevent the saw

blade from contacting the jig.

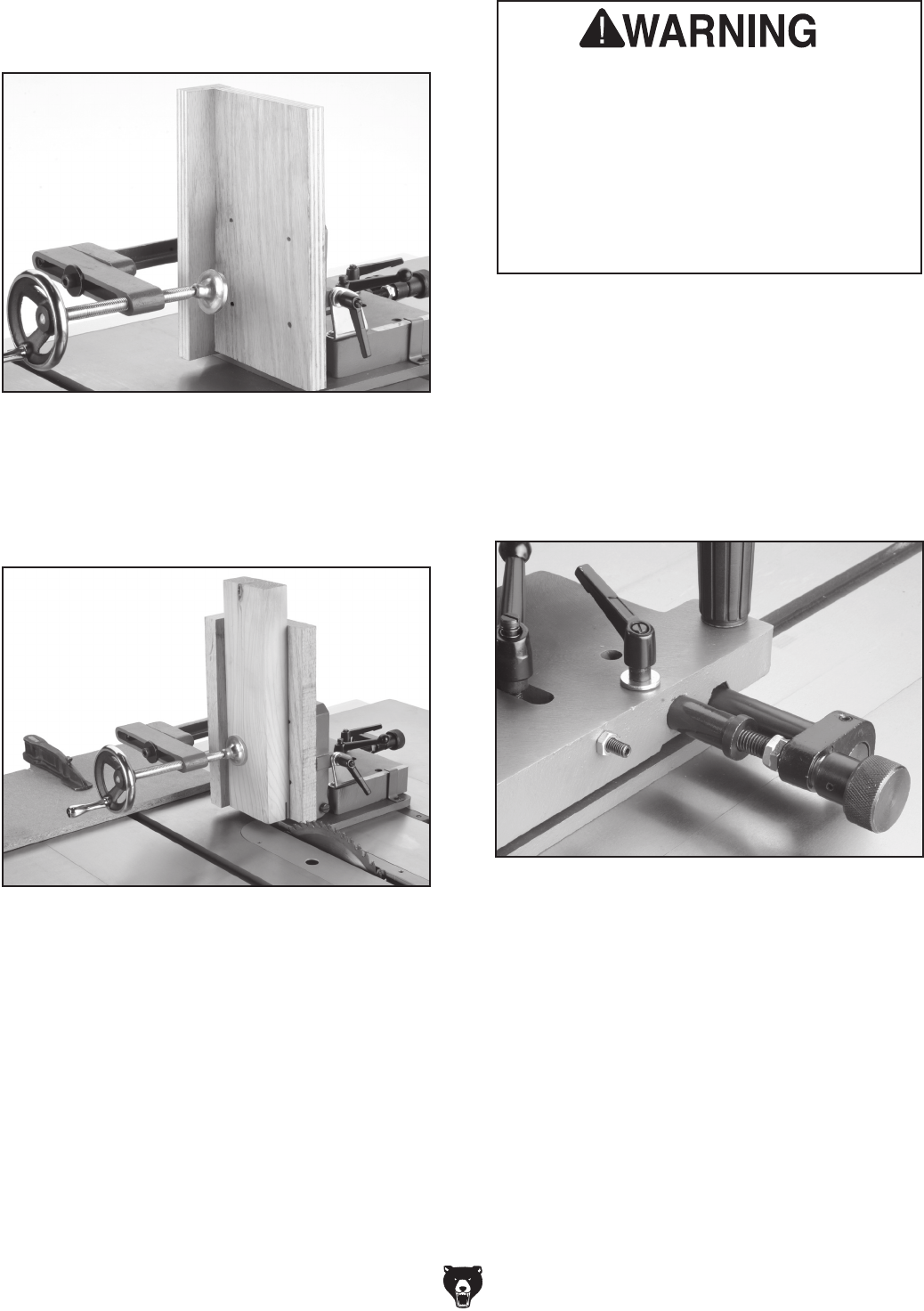

5. Slide the jig back to the base stop, place the

workpiece on the base stop, and clamp the

workpiece against spacer block and back

stop as shown in

Figure 20.

4. Cut a back stop backup board and screw it to

the back stop as shown in

Figure 19.

Figure 19. Back stop backup board.

6. Slide the jig up next to the saw blade, and use

the major and micro adjustments (

Figure 21)

to line up the layout lines on the workpiece

with the saw blade.

Note: The major adjustment sleeve allows

for quick adjustment of the jig positioning,

and the micro adjustment knob fine tunes the

quick adjustment that was made.

Figure 20. Clamping the workpiece.

Figure 21. Major adjustment sleeve and micro

adjustment knob.