-26- G5959/G9957 12" Table Saw

4. If anything appears abnormal, immediately

turn off the saw and fix the problem. If a

problem exists that is beyond the scope of

this manual, call our service department.

5. If the saw is behaving normally, turn it off and

prepare to make a cut according to the

instructions outlined in the following sec-

tions.

Blade Selection

Choosing the correct blade for the job is essential

for the safe and efficient use of your table saw.

Ignoring this important step could result in dam-

age to the saw and serious injury to the operator.

Documented below are the most common saw

blades and their uses.

1. Rip Blade: Used for cutting with the grain.

Typically, 14" rip blades have between 30-40

teeth, flat-top ground tooth profile and large

gullets to allow for large chip removal. See

Figure 31.

Figure 31. Ripping blade.

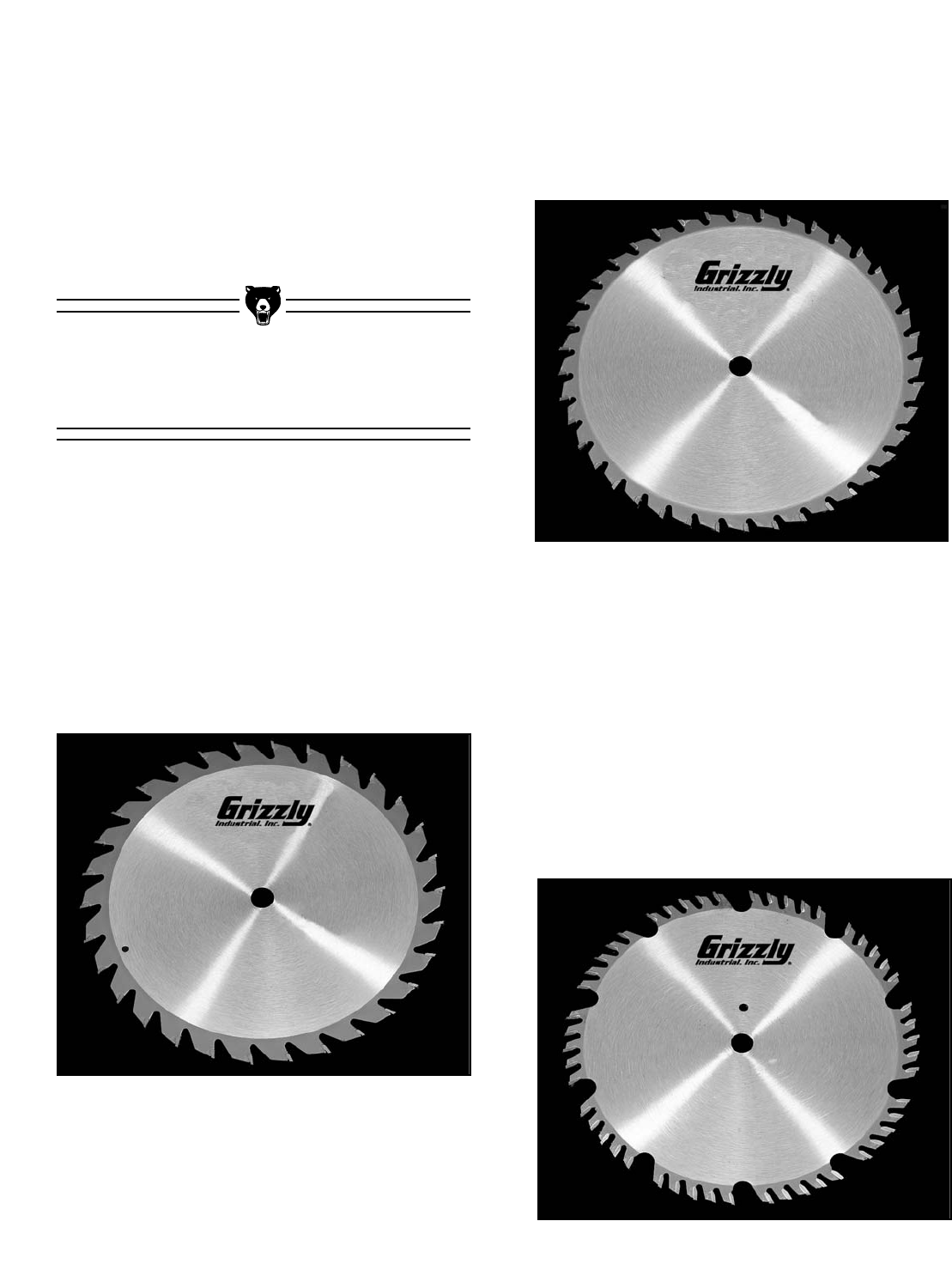

3. Combination Blade: Used for cutting with

and across the grain. A compromise

between a rip blade and a cross-cut blade, a

12" combination blade will typically have

between 50-60 teeth, an alternate top bevel

and flat or alternate top bevel and raker tooth

profile. The teeth are arranged in groups of

five. The gullets are small and shallow within

the groups of five teeth, similar to a cross-cut

blade; then large and deep between the

groups, like a ripping blade. See Figure 33.

Figure 33. Combination blade.

2. Cross-cut Blade: Used for cutting across

the grain. 12" cross-cut blades have

between 60-80 teeth, alternate top bevel or

steep alternate top bevel tooth profiles, small

hook angle and a shallow gullet. See Figure

32.

Figure 32. Cross-cutting blade.