-32- G5959/G9957 12" Table Saw

SECTION 7: MAINTENANCE

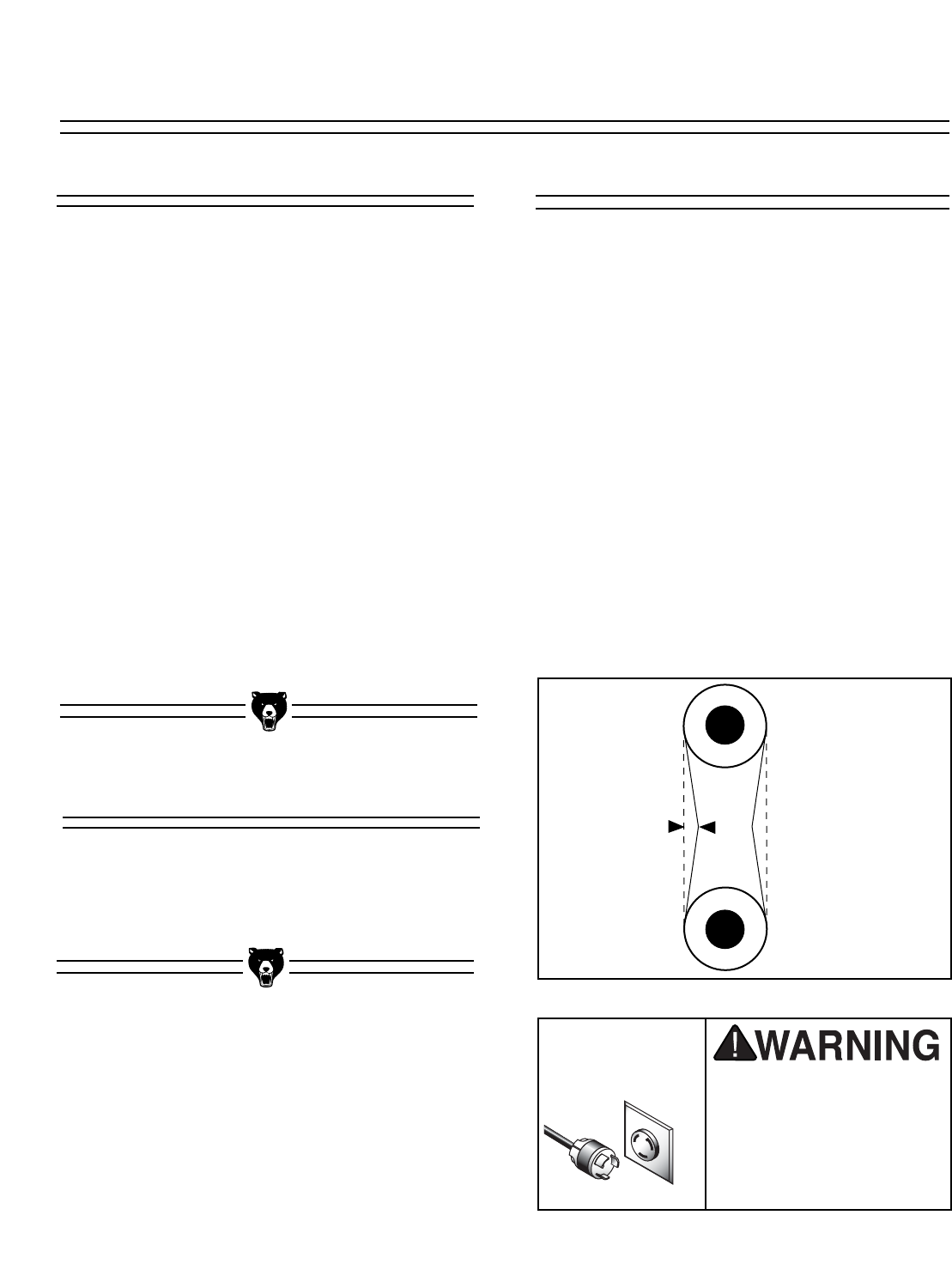

V-Belt

To ensure optimum power transmission from the

motor to the blade, the V-belts must be in good

condition and operate under proper tension.

When replacing V-belts, it is important to replace

all four at the same time - even if they do not all

appear worn.

Belt tension should be checked at least every 3

months; more often if using the table saw inten-

sively.

The V-belts are accessed through the cavity on

the right side of the saw. They link the arbor and

motor pulleys. To check V-belt tension:

1. Squeeze the center of each V-belt.

2. Note the amount of deflection. Deflection

should be approximately

3

⁄4

" as shown in

Figure 42.

Figure 42. Proper amount of V-belt deflection.

Table

Regular periodic maintenance on your Model

G5959/9957 will ensure its optimum performance.

Make a habit of inspecting your machine each

time you use it. Check for the following conditions

and repair or replace when necessary:

1. Loose mounting bolts.

2. Worn switch.

3. Worn or damaged cords and plugs.

4. Damaged V-belt.

5. Any other condition that could hamper the

safe operation of this machine.

6. Inspect blades for damage.

7. Guard alignment and operation.

General

Disconnect power to the

machine when perform-

ing any maintenance or

repairs. Failure to do this

may result in serious

personal injury.

!

3

⁄4"

Table can be kept rust-free with regular applica-

tions of products like Boeshield

®

T-9. For long

term storage you may want to consider products

like Kleen Bore's Rust Guardit™.