SKU 93257 For technical questions, please call 1-800-444-3353 PAGE 11

INSPECTION, MAINTENANCE, AND CLEANING

1. Inspect the Nailer frequently and lubricate periodically with pneumatic Tool Oil

(93). Then, wipe dry. Do not use detergent oil or additives as these lubricants will

cause accelerated wear to the internal seals. Use the included Hex Wrench (94)

to ensure bolts are properly tightened; only a qualified technician should open the

Nailer to repair internal parts.

2. Inspect the Filter Unit (80) before each use and clean or replace as necessary.

Dirt and water in the Filter Unit are major causes of pneumatic tool wear. Use an

oiler/filter in the compressed air system for better performance and longer tool life.

The filter must have adequate flow capacity for the specific application.

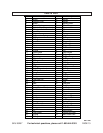

(See Assy. Diagram.)

3. Clean the external parts of the Nailer with a clean cloth and mild detergent or

nonflammable solvent. Then, dry.

4. Store the tool in a clean, dry, safe location out of reach of children.

5. WARNING: All maintenance, service, or repairs not listed in this manual

are only to be attempted by a qualified service technician.

Anytime any maintenance or repairs are done, FIRST:

1. Disconnect the Nailer from its air supply.

2. Empty the Magazine (85) completely.

3. Attempt to fire the Nailer into a piece of scrap wood to ensure that it is disconnected

and is incapable of firing any Nails.