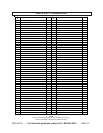

TROUBLESHOOTING

Problem Possible Cause Possible Solution

Gouging at ends of board. 1. Dull Knives.

2. Inadequate support of long boards.

3. Rollercase not level with base.

4. Uneven force on cutterhead.

5. Boards not butted properly.

1. Replace Knives.

2. Support long boards (over 24”) with

support stands (not included).

3. Adjust rollercase.

4. Gently push board when board is

in contact with only one feed roller.

5. Butt end to end each piece of stock

as boards pass through Planer.

Torn grain. 1. Too deep a cut.

2. Dull knives.

3. Knives cutting against grain.

1. Reduce depth of cut.

2. Replace knives.

3. Cut with the grain.

Rough, raised grain. 1. Too deep a cut.

2. Dull knives.

3. Moisture content too high.

1. Reduce depth of cut.

2. Replace knives.

3. Use dried wood.

Fuzzy grain. 1. Moisture content too high. 1. Use dried wood.

Uneven depth of cut. (side to side) 1. Rollercase not level with Planer

base.

1. Adjust table level.

Rollercase elevation adjusts with

difficulty.

1. Elevation screws/columns dirty.

2. Elevation screws worn.

3. Rollercase not parallel with Planer base.

1. Clean and lubricate elevation

screws/columns.

2. Replace elevation screws.

3. Adjust rollercase.

Board thickness does not match

depth of cut scale.

1. Indicator not set correctly. 1. Adjust indicator and tighten securely.

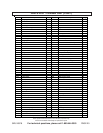

Board feeds inside Planer, but stops

Moving past the outfeed roller.

1. Outfeed rollers cannot rotate due to

clogging of chips.

2. Too much pressure on the cutterhead

from long workpiece.

1. Clear the clogging. Clean the dust

collector system.

2. Support long boards (over 24”) with

support stands (not included).

V-belt slipping. 1. Loose V-belt. 1. Have a qualified service technician

replace V-belt.

Rollercase cannot be lowered. 1. Workpiece thickness gauge setting

restricts rollercase movements.

1. Reset thickness gauge setting.

Excessive fan noise. 1. Large piece of wood in fan housing.

2. Loose fan.

1. Remove blade guard and clear

housing chamber.

2. Open blade cover and tighten fan bolt.

Motor overheats. 1. Improper motor cooling.

2. Motor overload.

1. Clean sawdust from motor.

2. Reduce depth of cut.

Circuit breaker/fuse trips. 1. Dull knives.

2. Motor overload.

3. Improper capacity of circuit

breaker/fuse.

1. Replace knives.

2. Reduce depth of cut.

3. Use proper capacity circuit breaker/fuse.

Planer will not operate. 1. No power to Planer.

2. Motor overload protection tripped.

3. Defective switch or wiring.

1. Make sure Planer is plugged into a

working, 120 VAC, grounded, electrical

outlet.

2. Reset motor circuit breaker.

3. Have a qualified service technician

repair Planer.

SKU 95518 For technical questions, please call 1-800-444-3353 PAGE 18