SKU 98733 For technical questions, please call 1-800-444-3353. Page 7

FUNCTIONAL DESCRIPTION

Specications

Working Air

Pressure Range

70-120 PSI* (Depending on

nail length and wood density)

Air Inlet 1/4” -18 NPT

Nail Type

.113”-.131” diameter, 2-3/16” to

3-1/2” L, 21° Nails

Fastener Type Plastic Collated Full Head Nails

Magazine

Capacity

60 Nails

Air Consumption

3 CFM @ 90 PSI

(Intermittent use)

12 CFM at 90 PSI

(Required for continuous use)

Safety Trigger Single Sequential Actuation

* The pressure setting must not exceed the job

site regulations/restrictions.

INITIAL TOOL SET UP/

ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Unpacking

When unpacking, check to make sure

item is intact and undamaged. If any parts

are missing or broken, call Harbor Freight

Tools at the number shown throughout the

manual as soon as possible.

This air tool may be shipped with a •

protective plug covering the air inlet.

Remove this plug before set up.

Air Supply

TO PREVENT

EXPLOSION:

Use only clean, dry, regulated,

compressed air to power this

tool. Do not use oxygen,

carbon dioxide, combustible

gases, or any other bottled

gas as a power source for this

tool.

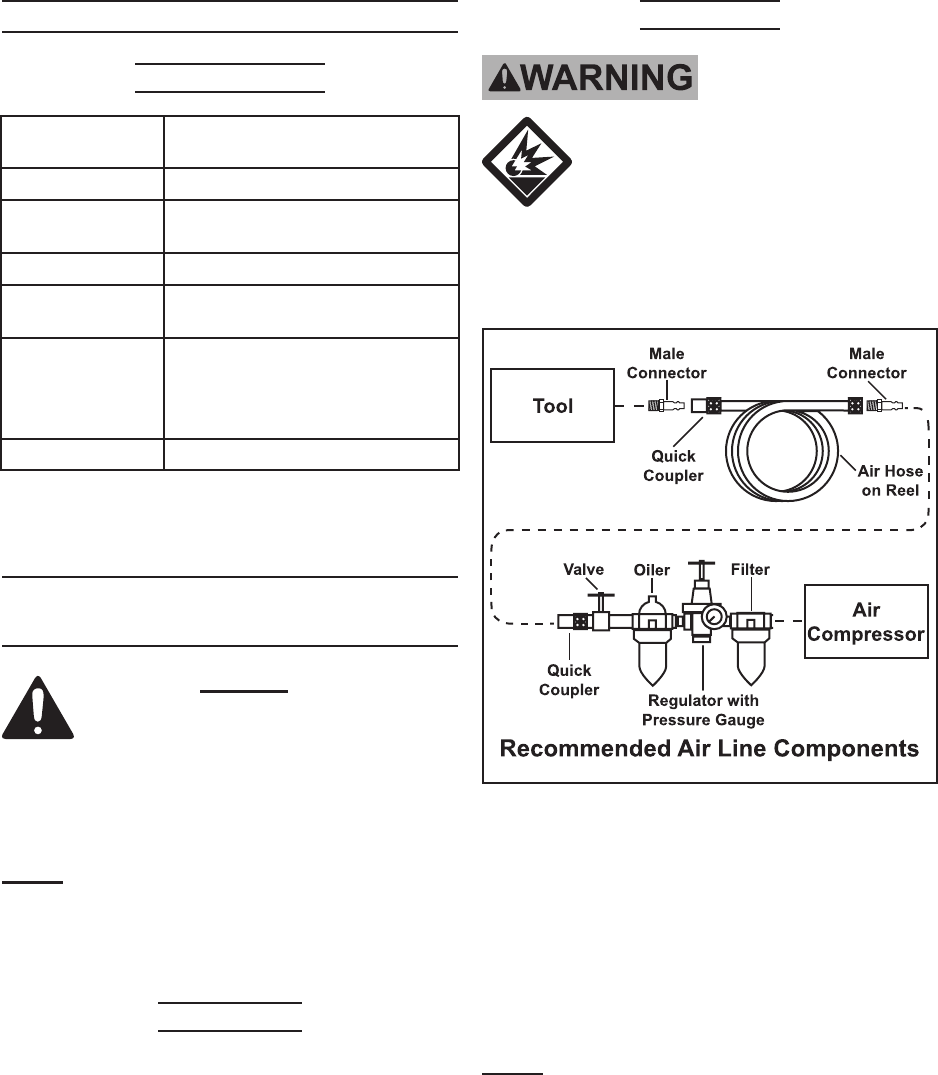

1. Incorporate an in-line oiler, shut-off

valve, regulator with pressure gauge,

and lter for best service, as shown in

the diagram above. An in-line shut-

off valve is an important safety

device because it controls the air

supply even if the air hose is rup-

tured.

Note: If an automatic oiler system is not

used, add a few drops of Pneumatic

Tool Oil to the airline connection be-

fore operation. Add a few more drops

after each hour of continual use.

Attach an air hose to the compres-2.

sor’s air outlet. Connect the air hose

to the air inlet of the tool. Other com-

Revised 09i; 09l