SKU 99640 For technical questions, please call 1-800-444-3353. Page 11

hardwood ooring. To change the

Spacer:

a. Empty the Magazine (52) complete-

ly.

b. Attempt to re the Floor Nailer into a

piece of scrap wood to ensure that it

is disconnected and is incapable of

ring any nails/staples.

c. Set the tool on its side to expose the

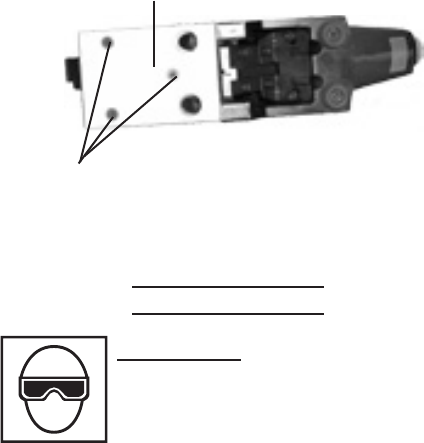

three Screws (37).

d. Remove the three Screws (37).

Then, remove the Spacer.

e. Align the three mounting holes in the

replacement Spacer with the three

threaded mounting holes.

f.

Screws (37)

Spacer (36)

Secure the Spacer to the tool, using

the three Screws (37).

Clearing Jams

WARNING! Anytime any

maintenance or repairs are

done (including clearing

jams), wear ANSI-approved

impact safety goggles and appro-

priate hearing protection. THEN:

1. Disconnect the Floor Nailer from

its air supply.

2. Empty the Magazine and Slide

Load Magazine completely.

3. Try to re the Nailer into a piece of

scrap wood or ooring to ensure

that it is disconnected and inca-

pable of ring any nails/staples.

4. Occasionally, a cleat nail/staple may

become jammed in the ring mecha-

nism of the Floor Nailer, making the

tool inoperable.

5. To remove a jammed cleat nail/

staple, disconnect the tool from its air

supply, push in the Lock and slide the

Magazine back until it locks in place.

Then, lean the Floor Nailer back.

6. Remove all cleat nails/staples from

the Magazine. Then press the Lock

and slide the Moveable Magazine

forward all the way.

7. Attempt to re the Floor Nailer into a

piece of scrap wood to ensure it is

disconnected and is incapable of r-

ing any nails/staples.

8. With the Driver Guide (49) facing

away from you, remove the two Bolts

(42, 43). Then remove the Driver

Guide to expose the jammed cleat

nail/staple.

9. Remove jammed cleat nail/staple.

Replace the Driver Guide and Bolts.

10. Reload the tool with cleat nails/sta-

ples. Then, reconnect the air supply

hose to the tool.

11. Press the Driver Guide against a

piece of scrap wood, and test re the

Nailer several times while checking

for proper operation. If the tool is

properly ring, you may continue us-

ing the tool. If the tool fails to perform

properly, immediately discontinue use

and have the tool repaired by a quali-

ed service technician.

12. When nished working, disconnect

the air supply. Remove nails/staples.

Discharge any trapped air. Then,

Rev 09i