–

13

–

English

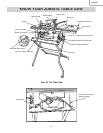

Impro

per splitter alignment can cause “kickback”

and serious injury

Fig.

I

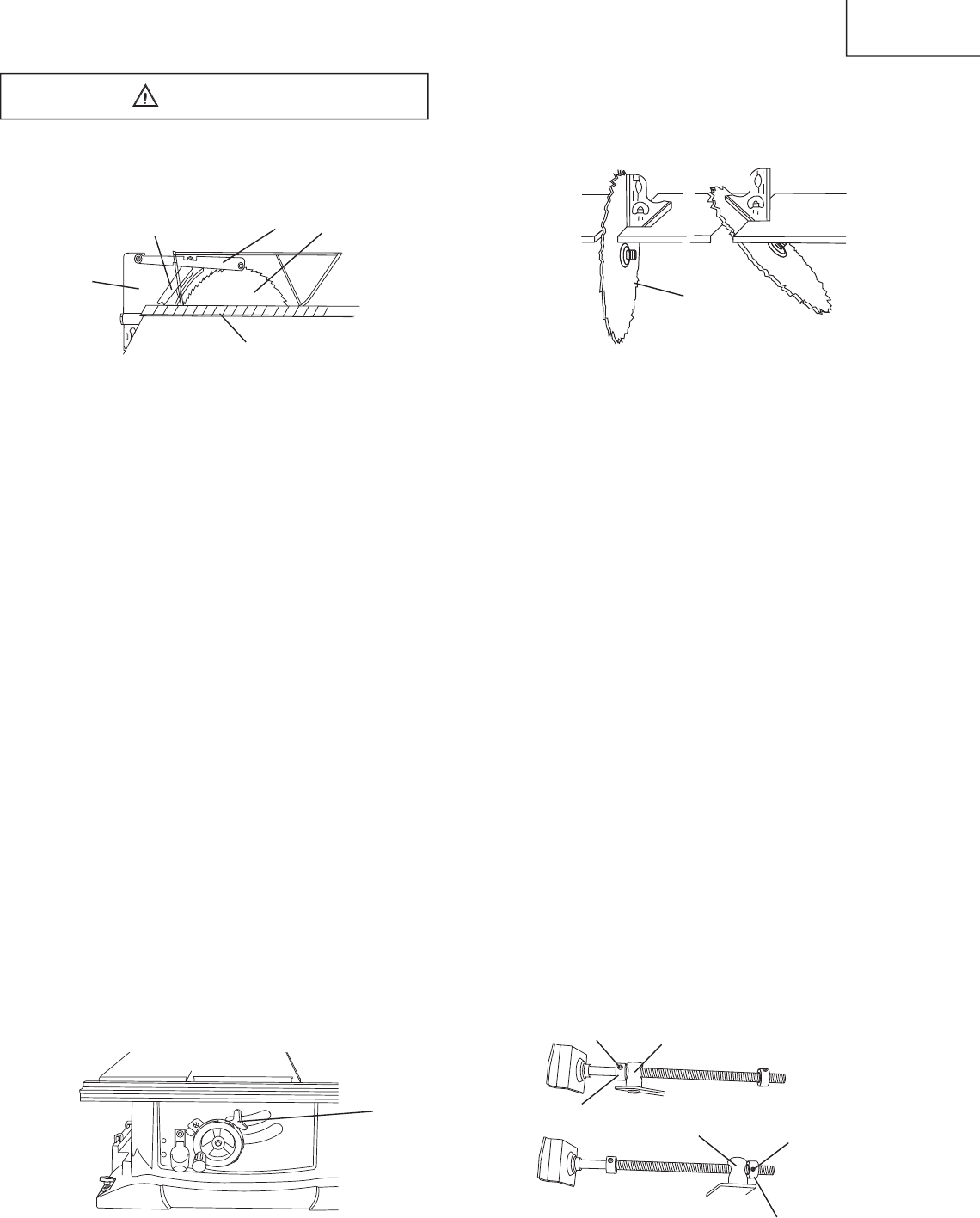

ADJUSTING THE 90°(0

0

) AND 45° POSITIVE STOPS

(FIG. J, K, L)

Your saw has positive stops that will quickly position

the saw blade at 90°

(0

0

)

and 45

0

to the table. Make

adjustments only if necessary.

90°(0

0

) Stop

1. Disconnect the saw from the power source.

2. Turn the blade elevation handwheel and raise the

blade to the maximum elevation.

3. Loosen the blade bevel lock knob (1) and move the

blade to the maximum vertical position, then tighten

the lock knob (1).

4. Place a combination square on the table and against

the blade (2) to determine if the blade is 90°(0

0

) to

the table. (Fig. K)

5. If the blade is not 90°(0

0

) to the table, loosen the two

set screws (4), located on the collar (5) underneath

the table saw (Fig. L) with the hex key, and back off

the collar.

6. Loosen the bevel lock knob, turn the blade tilting

handwheel to move the blade until it is 90°(0

0

) to the

table and tighten the bevel lock knob.

7. Adjust the collar (5) so it contacts the bracket (3)

when the blade is 90°(0

0

) to the table. Tighten the

two set screws (4). (Fig.L)

Fig.

J

Fig. K

45° Stop

1. With the blade in the upright 90°(0

0

) position, loosen

the bevel lock knob and move the blade to the

maximum bevel angle.

2. Place the combination square on the table as shown

in Fig. K to check if the blade is 45° to the table.

3. If the blade is not 45° to the table, loosen the two set

screws (4), located on the collar (5) nuderneath the

table saw, with the hex key, and back off the collar.

(Fig. L)

4. Loosen the bevel lock knob, turn the blade tilting

handwheel to move the blade until it is 45° to th

e

table

and tighten the blade bevel lock knob.

5. Adjust the collar (5) so it contacts the bracket (3)

when the blade is 45° to the table. Tighten the two

set screws

.

BLADE TILT POINTER

1. When the blade is positioned at 90°(0

0

), adjust the

blade tilt pointer to read 0° on the scale.

2. Loosen the mounting screw, position pointer over

0° and tighten the screw.

NOTE:

Make a trial cut on scrap wood before making

critical cuts. Measure for exactness.

Fig.

L

WARNING

1

90

0

(0

0

)

45

0

2

Anti-kickback Pawl

8

10

9

Straight edge

45

0

90

0

(0

0

)

3

3

4

5

3

4

5