counterclockwise, then adjust the right side screw(3)

clockwise.

2. Remeasure, as described in steps 4 to 9 in the prior

section

3. When alignment is achieved, turn the left screw (2)

nutil it touches the pivot rod (4) then tighten both

nuts (1).

If the blade is partial to left side:

4.

Loosen the two nuts (1) and tighten the

left

screw

(3)

counterclockwise, then adjust the left side screw (2)

clockwise.

5. Remeasure, as described in steps 4 to 9 in the prior

section.

6.

W

hen alignment is achievde, turn the right screw (3)

nutil it touches the pivot rod (4) then tighten both

nuts (1).

Fig.

N

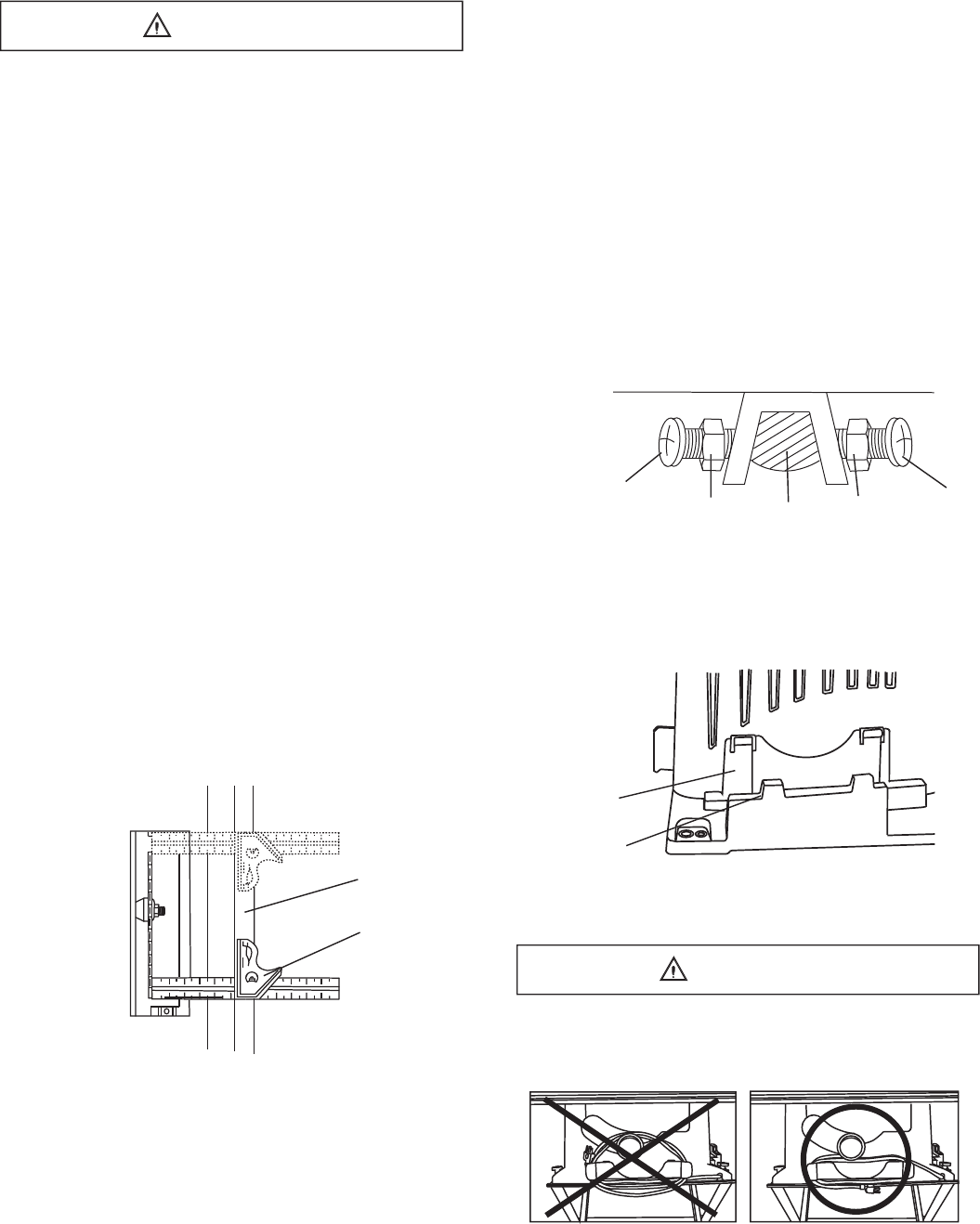

STORAGE (FIG. O, P)

Rip fence and miter gauge (Fig. O)

Storage brackets for the rip fence (2) and miter gauge

(3) are located on the left side of the saw housing.

Fig.

O

Cord wrap

(Fig. O-1)

Do not wrap the cord around the dust port.

Fig. O-1

BLADE PARALLEL TO THE MITER GAUGE GROOVE

(FIG. M, N)

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

This adjustment was made at the factory, but it

should be rechecked and adjusted if necessary.

This adjustment must be correct or kickback could

result in a serious injury and accurate cuts can not

be made.

1. Remove the safety switch key and unplug the saw.

2. Remove the blade guard for this procedure but

reinstall and realign after adjustment.

3. Raise the blade to the heighest position and set at

the 0° angle (90

0

straight up)

4. Select and mark with a felt tip marker, a blade tooth

having a “right set” and

rotate the blade so the

marked tooth is 1/2

in

. Above th

e table.

5. Place the combination square base (1) into the right

side miter gauge groove (2). (Fig.M)

6. Adjust the ruler so it touches the front marked tooth

and lock ruler so it holds its position in the square

assembly.

7. Rotate the blade to the rear of the saw bringing the

marked tooth approximately ½” above the blade.

8

. Carefully slide the combination square to the rear

until the ruler touches the marked tooth.

9. If the ruler touches the marked tooth at the front and

rear position, no adjustment is needed at this time. If

not or the base of the miter gauge groove, perform

adjustment procedure described in next section.

Fig.

M

Additional Blade Adjustments (Fig. N)

NOTE:

The adju

sting nuts are 8 mm.

The adjusting mechanism is located above the blade

height adjusting hand wheel nuder the tabletop. If the

front and rear measurments are not the same.

If the blade is partial to right side:

1. Loosen the two nuts (1) and turn the left screw (2)

2

3

1

1

4

2

3

WARNING

2

1

- 14 -

WARNING