OM-249 498 Page 30

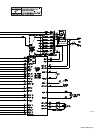

7-4. Changing Drive Roll Or Wire Inlet Guide

! Turn off welding power

source.

1 Inlet Wire Guide Securing

Screw

2 Inlet Wire Guide

Loosen screw. Slide tip as close to

drive rolls as possible without

touching. Tighten screw.

3 Retaining Pin

To remove drive roll, push drive roll

in and rotate it (1/4 turn) to the open

slot and slide it out over the

retaining pin.

To secure drive roll, locate open slot

and push drive roll completely over

retaining pin, then rotate drive roll

(1/4 turn) to closed slot.

4 Drive Roll

The drive roll consists of two

different sized grooves. The

stamped markings on the end

surface of the drive roll refers to the

groove on the opposite side of the

drive roll. The groove closest to the

motor shaft is the proper groove to

thread (see Section 5-16).

Tools Needed:

250 763-A

3

1

2

4

.030/.035

Smooth

Groove

Stamped

.030..035 VK

.030/.035

Knurled

Groove

Stamped

.030..035

.030/.035

V Groove

Stamped

.024

.023/.025

V Groove

Stamped

.030..035