OM-487 Page 29

7-7. Adjusting Engine Speed

If the engine does not start and stop properly, verify the fuel solenoid is installed

properly before adjusting engine speed (see Section A following).

If the engine does not stay at idle speed, verify the throttle solenoid is installed and

adjusted properly before adjusting engine speed (see Section B following).

If the engine runs properly but the speeds are incorrect, do not adjust the

solenoids. Adjust the engine speed according to the instructions in Section C.

NOTE

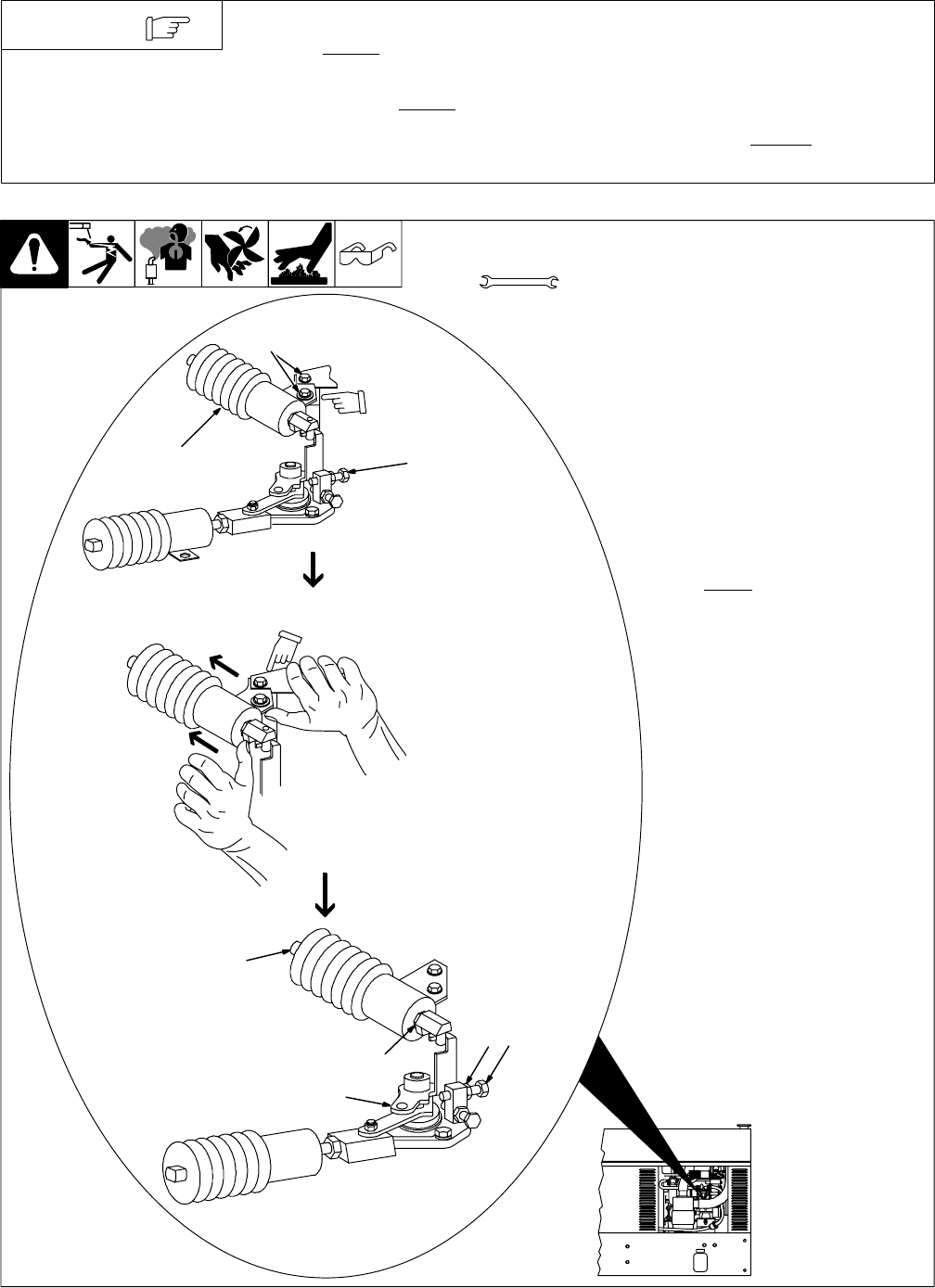

A. Checking Fuel Solenoid

Ref. ST-801 961 / ST-802 649

Y Stop engine.

If the engine does not start and stop when

using the Engine Control switch, check

the position of the fuel solenoid.

Adjusting Fuel Solenoid Position

1 Fuel Solenoid

2 Stop Screw

3 Fuel Solenoid Mounting Screws

. Stop screw is factory-set and should

not be adjusted.

When properly adjusted, the solenoid

bracket is slightly recessed from the edge

of the engine block and the solenoid link-

age easily travels between the stop screw

and the fuel solenoid internal stop.

If adjustment is necessary, loosen the so-

lenoid mounting screws and push the so-

lenoid bracket back toward engine as far

as possible.

Continue pushing on solenoid bracket in

a clockwise direction while tightening

mounting screws.

4 Shutdown Lever

5 Stop screw

6 Stop Screw Jam Nut

7 Fuel Solenoid Jam Nut

8 Plunger

. Stop screw is factory-set and should

not be adjusted.

Hold throttle solenoid in idle (energized)

position. If shutdown lever is touching or

within 1/16 in of stop screw, fuel solenoid

is properly adjusted.

If lever is more than 1/16 in. from stop

screw, check for clearance between jam

nut and fuel solenoid. If there is clearance

between jam nut and solenoid, loosen nut

and turn plunger clockwise until lever

touches stop screw. Retighten nut.

If there is no clearance between jam nut

and solenoid, loosen the solenoid mount-

ing screws and reposition the solenoid as

described at the beginning of this section.

Tools Needed:

Verify mounting

bracket is recessed

from edge of engine.

2

1

3

Tighten mounting screws when

solenoid is in correct position.

65

7

8

4

7/16 in

10, 14 mm