OM-487 Page 31

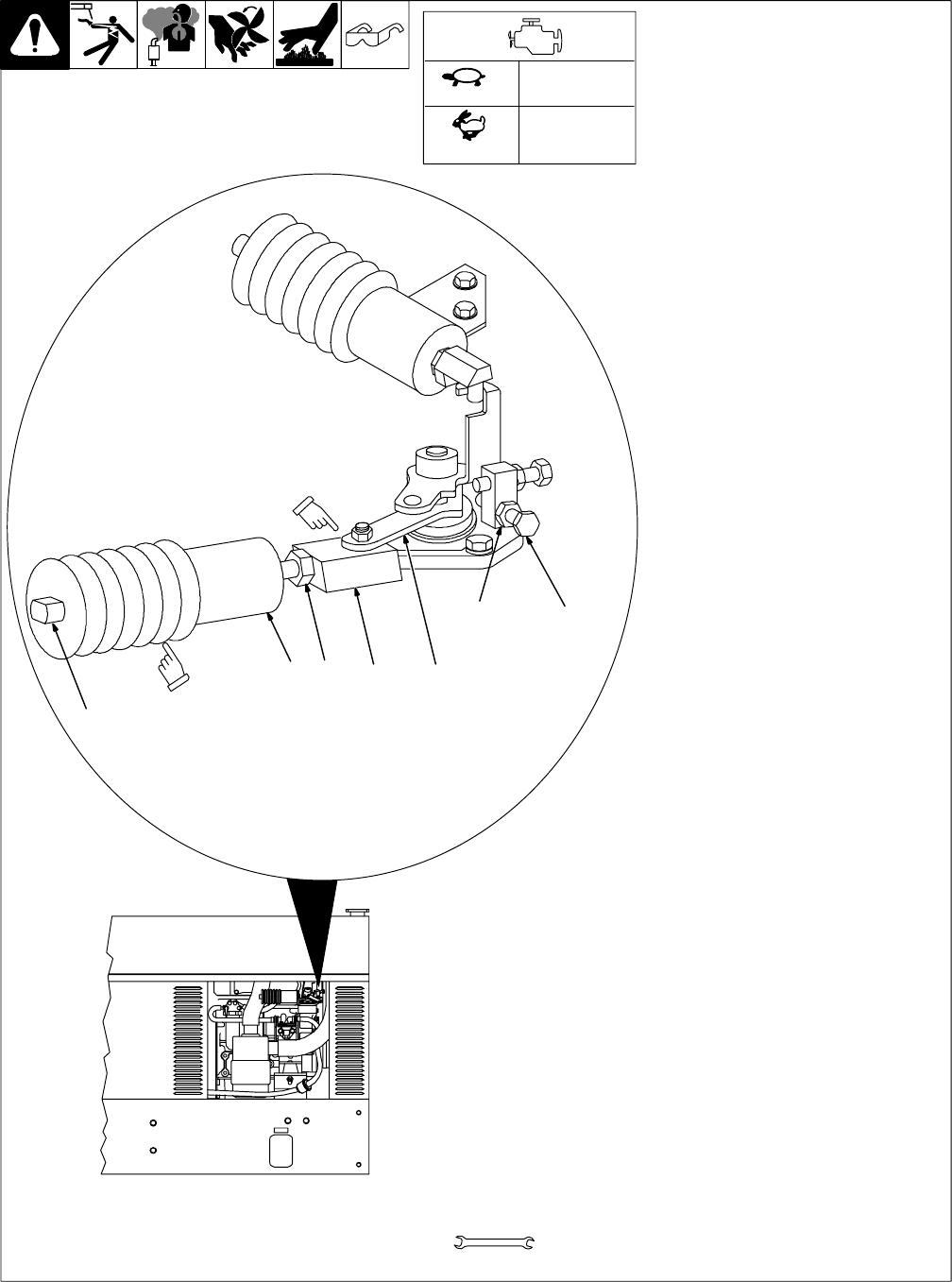

C. Making Engine Speed Adjustments

Ref. ST-801 961 / ST-801 963

. Before adjusting engine speed, verify

throttle solenoid is installed properly

(see Section B on previous page).

Check engine speeds with a tachometer

(see table). If necessary, adjust speeds as

follows:

Start engine and run until warm. Turn A/V

control to max.

Adjusting Idle Speed

Turn Engine Control switch to Run/Idle

position.

1 Throttle Solenoid

2 Idle Speed Jam Nut

3 Plunger

4 Throttle Link

5 Throttle Lever

Loosen jam nut. While holding throttle link

with a 3/8 in wrench, turn plunger clock-

wise to increase idle speed or counter-

clockwise to decrease idle speed.

. After adjusting idle speed, verify the

throttle link is parallel with the throttle

lever. If necessary, loosen the idle

speed jam nut and reposition the

throttle link.

. Do not twist solenoid boot while ad-

justing engine speed.

Tighten jam nut.

Adjusting Weld/Power Speed

Start engine and run until warm. Turn A/V

control to max.

6 Weld Speed Jam Nut

7 Adjustment Screw

Turn Engine Control switch to Run posi-

tion. Loosen nut and turn screw counter-

clockwise to increase speed. Turn screw

clockwise to decrease speed. Tighten nut.

2450 ± 100 rpm

3750 Max

3/8, 7/16 in

10, 14 mm

Tools Needed:

2

3

67

1

Be sure throttle link

is parallel with

throttle lever.

Do not twist

solenoid boot

while adjusting

engine speed.

45

Idle

Weld/Power