16

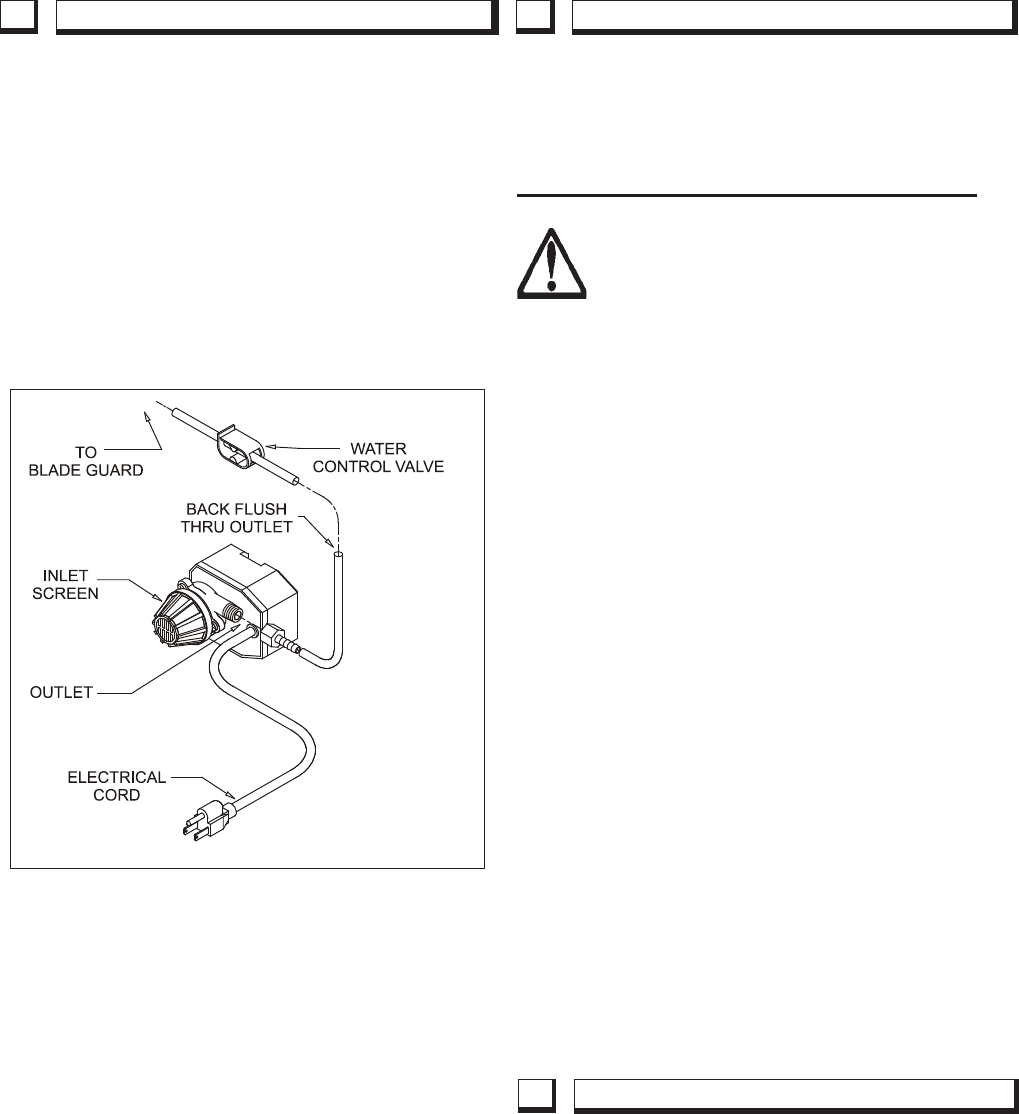

If Water Stops Flowing,

1. Stop Sawing, then

2. Disconnect Electrical Plug from Outlet, then

3. Remove the Pump, then

4. Back Flush.

Back ushing is done by forcing water into the pump

discharge and out through the screen. Most of the time

this procedure works, and the pump can be put back into

service. (See Figure below)

If the back ushing does not work, remove the screen and

turn the impeller manually, looking for and rinsing out the

impeller cavity of any dirt or foreign matter.

12 WATER PUMP TROUBLE-SHOOTING PROCEDURE

For quick supply of spare parts and to avoid any lost time,

it is essential to quote the data on the manufacturers plate

xed to the machine and the part number(s) and description

to be replaced with every order.

We carry out all repairs in the shortest possible time

and at the most economical prices. (See front page for

address and phone numbers) Contact your authorized

Husqvarna® dealer concerning maintenance and re-

13 REPAIRS

14 SPARE PARTS

V-Belt Tensioning with Cam Adjustment:

Always set the Motor Switch to OFF and un-

plug power cord before making any repairs

or adjustments to your saw.

This tile saw is belt driven. The standard unit uses a 6

groove Poly-V Belt. The tension is factory set, but on oc-

casion it may be necessary to adjust the belt especially

if it is being replaced. Again, adjust only with the saw

turned off and unplugged.

Tools needed: One 3/8” wrench, two 1/2” wrenches, one

3/8” Drive Extension x 8” or longer, and a 12” Straight

Edge.

1. Remove the Belt Guard to get access to the V-Belt.

a. Remove two 1/4”-20 Flange Bolts (3/8” wrench)

on top of Belt Guard.

b. Remove 5/16”-18 Bolt and Locknut (two 1/2”

wrenches) on side ange of Belt Guard.

2. Loosen the four 5/16”-18 Flange Bolts (1/2” wrench)

that hold the Motor to the platform.

3. Remove the Belt Guard for full access to belt and

pulleys.

a. Remove the two 1/4”-20 Flange Bolts (3/8”

wrench)

from top of Guard.

b. Remove the 5/16”-18 fasteners (two 1/2” wrench-

es) from the side of Belt Guard.

4. Rotate the belt tensioning Cam (1/2” Drive Extension)

to tighten the belt(s) to proper tension.

d. WIth belt tensioned, use the 12” Straight Edge to

check for correct pulley alignment and tighten the

engine mounting screws.

e. Replace the Belt Guard before operating the

tile saw. Always replace any guarding before start-