IRN37 - 160K - CC & IRN50 - 200H -CC & IRN75 - 160K - 2S & IRN100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

84

10.0 MAINTENANCE

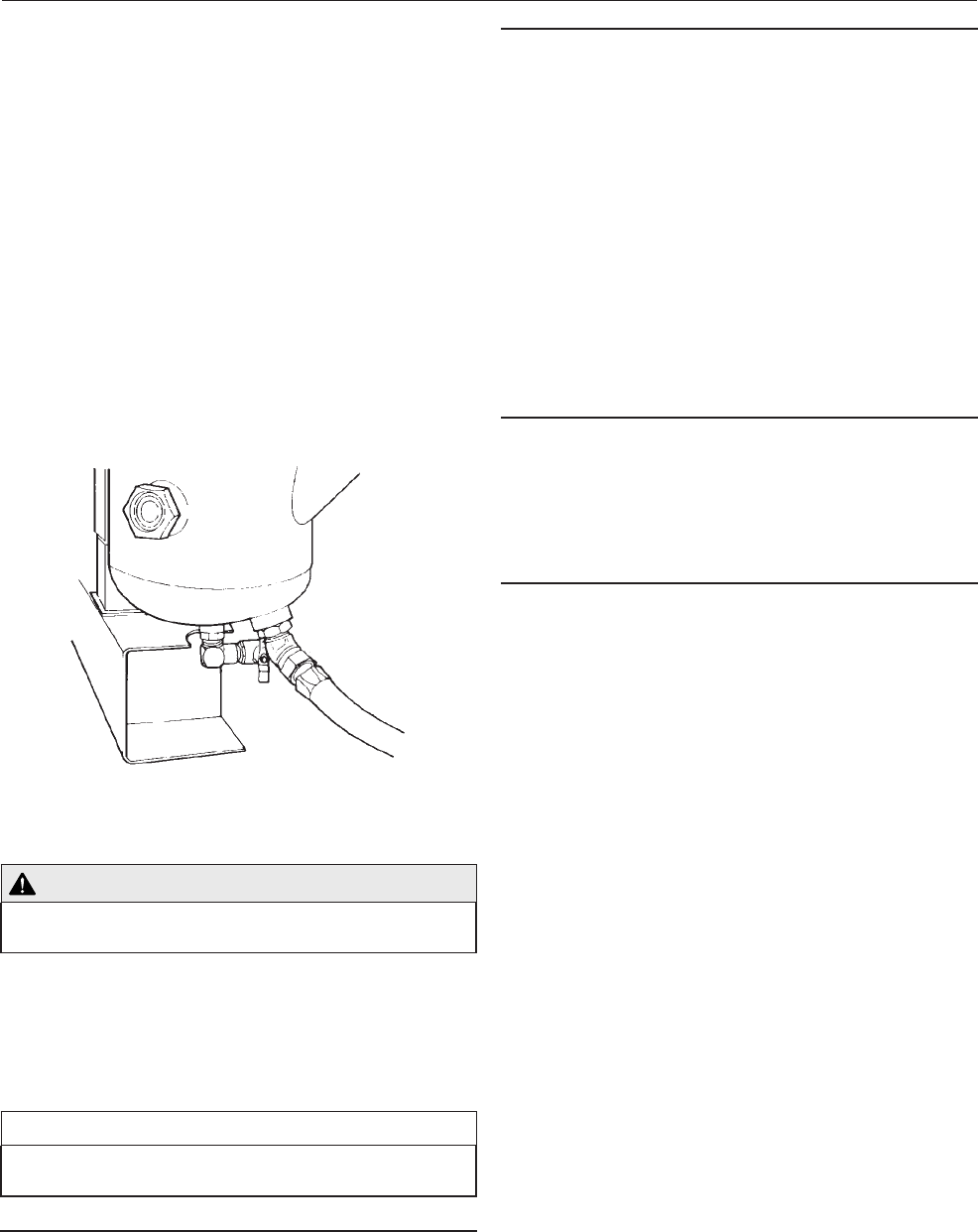

Drain sequence for N250/300H−2S

Remove plug from drain valve located on the bottom

of the separator tank.

Install supplied drain hose and fitting assembly in

end of drain valve and place end of hose in a suitable

pan.

Open drain valve to start drainage.

After draining is complete, close valve, remove hose

an fitting assembly from valve, and store in a suitable

location for future use.

Replace plug in end of drain valve.

Do not store drain hose in starter box after it has

been used to drain the separator tank.

Coolant fill quantity

250−300 hp − 2 stage

40.0 gallons (152 liters)

COOLANT DRAIN

CAUTION

Do not mix coolant types. Use only coolant specified

by IR

Start the compressor and check for leaks.

Check the coolant level, refilling if necessary.

Dispose of waste coolant in accordance with local

and governmental regulations.

NOTICE

Shorter coolant drain intervals may be necessary if

the compressor is operated in adverse conditions.

Food Grade Coolant option

SSR Food Grade Coolant is a polyalphaolefin base

coolant. Change after 1000 hours or every 6 months

whichever comes first. Do not operate unit past this

1000 hour change interval, as coolant degradation

will occur.

•

•

•

•

•

•

•

•

•

•

Coolant filter change procedure

Loosen filter element with the correct tool.

Remove the element from the housing.

Place the old element in a sealed bag and dispose of

in a safe way.

Clean the mating face of the housing.

Remove the new Ingersoll Rand replacement

element from its protective package.

Apply a small amount of coolant to the element seal.

Screw the new element down until the seal makes

contact with the housing, then hand tighten a

further half turn.

Start the compressor and check for leaks and check

the coolant level.

Separator element checking procedure

With the compressor running on load, check the

separator differential pressure via the Intellisys controller.

It will be necessary to change the element if the

differential pressure equals zero or exceeds 1 bar

(12 psig).

Separator element change procedure

Remove all the capscrews securing the cover to the

tank except the screw opposite the pivot bolt which

should be left engaged by 2−3 threads with at least

6.5mm (0.25”) clearance from the screw head to the

lid. Rotate the jacking bolt clockwise until the cover

lifts off the tank at least 2mm (0.08”) all the way

around the tank. The cover can now be rotated to

allow access to inside the tank.

Carefully lift out the element spacer and retain for

reassembly. Do not damage the flat surfaces of the

spacer as this may cause higher oil carryover or leaks.

A hoist is available for 175HP (90kW) machines and

above if required.

Carefully withdraw the used element, place it in a

sealed bag and dispose of it safely.

Remove the O−rings from the top of the tank, the

separator element sealing face and the scavenge

tube sealing face.

Clean the surfaces on both the tank and the cover.

Install new O−rings

Install replacement element remembering to fit the

small O−ring on the scavenge tube and positioning

the tube into the matching hole in the Separator

Tank

Re−fit the separator element spacer with the notch

over the scavenge tube.

Rotate the tank cover back into position taking care

not to damage the O−ring, and locate the cover

using 2 capscrews but do not tighten down.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•