IRN37 - 160K - CC & IRN50 - 200H -CC & IRN75 - 160K - 2S & IRN100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

90

10.0 MAINTENANCE

No Loss Drain Trap (where fitted) Check / Cleaning

Remove the four socket head screws then carefully

split the trap. Clean and inspect all internal parts

with particular attention to the water level sensor(s).

If the stainless steel strainer mesh is blocked, remove

it and clean in a weak detergent solution.

Replace any defective parts (see parts manual for

repair kit).

Re−assemble and later, with machine running, check

that condensate is expelled at regular period and no

alarms are signaled on trap or on INTELLISYS display.

Fluid and Vibration Monitoring

Ingersoll Rand recommends incorporating predictive

maintenance, specifically the use of coolant and vibration

analysis, into all Preventative Maintenance programs.

Predictive Maintenance is designed to increase system

reliability and prevent costly downtime. Through the

use of sophisticated diagnostic tools, including fluid,

vibration, and optional air analysis, IR Certified Service

Technicians can identify and correct potential problems

BEFORE they can cause expensive unscheduled

downtime.

How does predictive analysis work? By establishing an

initial baseline for normal operation, and then regularly

monitoring fluid and vibration conditions, any sudden

deviation or significant increase from this baseline can

be identified and investigated to pinpoint the cause.

More quickly diagnosing potential problems can directly

save money by preventing costly failures and reducing

or eliminating downtime. In addition, regular condition

monitoring also helps to maximize the time between

expensive preventative maintenance intervals, such as

component rebuilds and coolant changes.

•

•

•

•

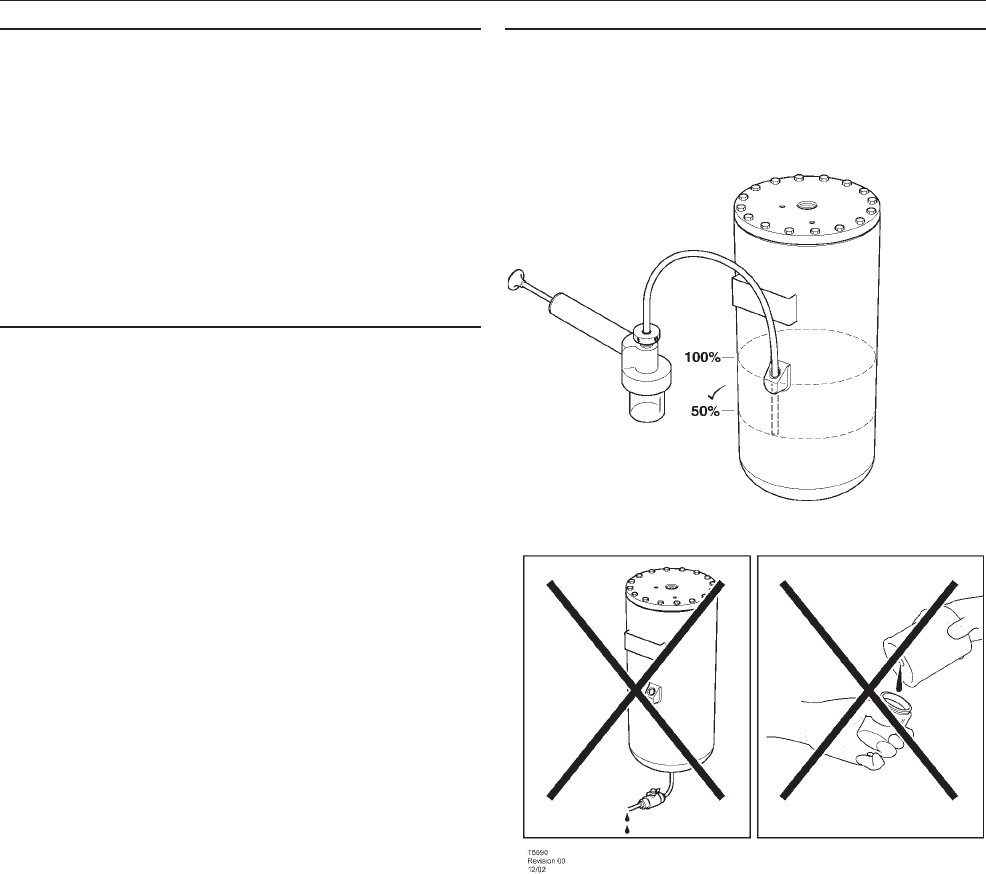

Coolant Sampling Procedure

Bring unit up to operating temperature. Draw sample,

using pump kit, from separator tank port. DO NOT draw

sample from drain port or oil filter. Use a new hose on

pump for each sample, failure to do this can give false

readings.