IRN37 - 160K - CC & IRN50 - 200H & IRN75 - 160K - 2S & IRN - 100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

93

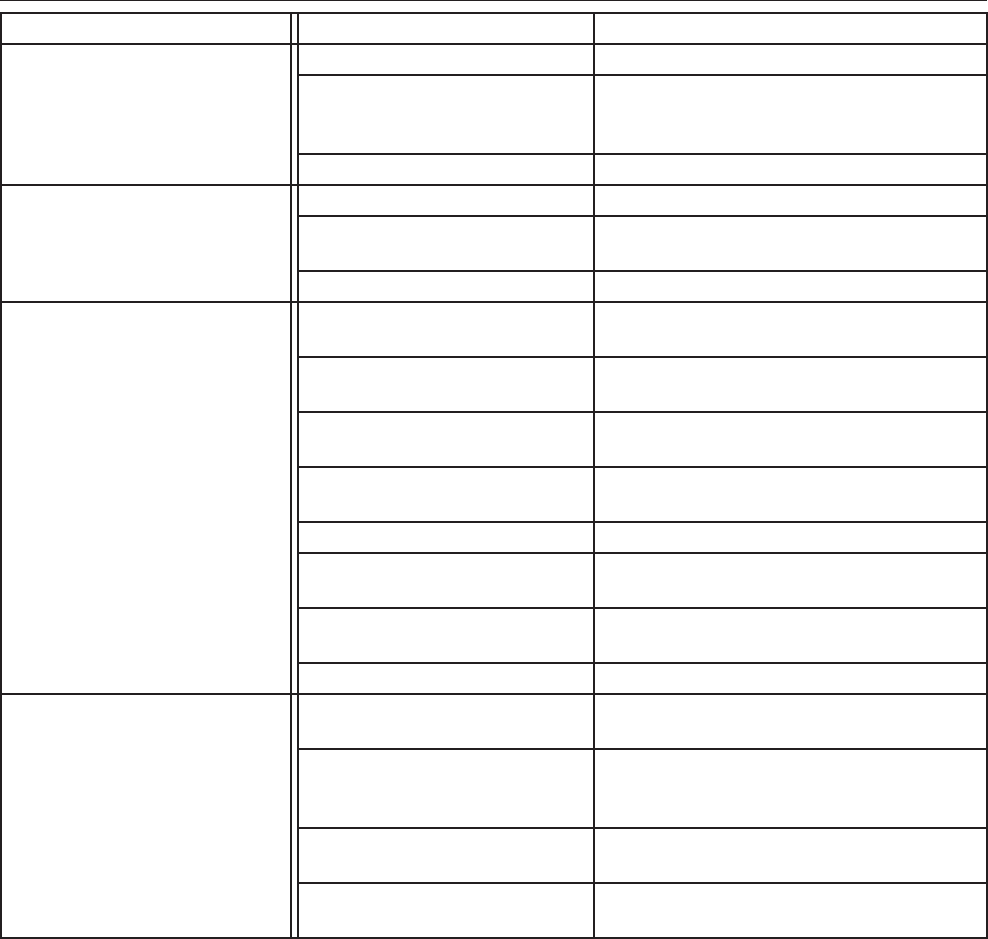

11.0 FAULT FINDING

SYMPTOM FAULT REMEDY

Pressure produced

by compressor is too

highcompressor is too high

due to speed not reducing as

demand reducesreduces

Intellisys set incorrectly Check and modify settings

Pressure transducer may be

faulty, incorrectly calibrated or

not receiving pressure signal

Recalibrate or replace

Drive settings fault Contact your local IR representative

Compressor discharge air too

hot

High ambient temperature Review installation and system parameters

Insufficient cooling air Check ducting and cooling air path, check

direction of blower rotation

Blocked aftercooler matrix Clean or replace

Compressor package produces

excessive noise

Panels or doors are not closed

properly

Rectify fault

Air leaks from internal pipework /

components

Overhaul or replace

Blower or blower motor bearings

worn

Overhaul or replace

Loose debris impacting on

blower during rotation

Remove and rectify any damage

Blowdown valve stuck open Overhaul or replace

Pressure relief valve not seating

correctly

Overhaul or replace

Vibration due to motor, airend or

blower imbalance

Overhaul or replace

Airend requires overhaul Contact your local IR representative

Discharge air is contaminated

with coolantcoolant

Scavenge pipe is blocked, broken

or o−ring is not sealing

Clean or replace

Separator element is punctured,

or incorrect, or requires changing,

or not sealing correctly

Replace

Incorrect coolant has been added Drain system, check for damage. Clean, refill

with correct coolant.

System has been overfilled with

coolant

Check for damage, drain excess.