8.

Align holes on bed with those in the stand top

and fasten with eight hex socket cap screws

(5/16"x1") , eight lock washers (5/16"), and

eight nuts (5/16") supplied. Note: Two larger

hex socket cap screws and washers will be

used later to attach the bed extension to the

bed.

9.

Tighten eight hex socket cap screws with a hex

wrench.

1O. Tighten all stand hardwaremakingsure it is

stable on the shop floor.

11. Attach bed extensionto bed usingtwo hex

socket cap screws (3/8"x1") and two lock

washers (3/8") supplied.

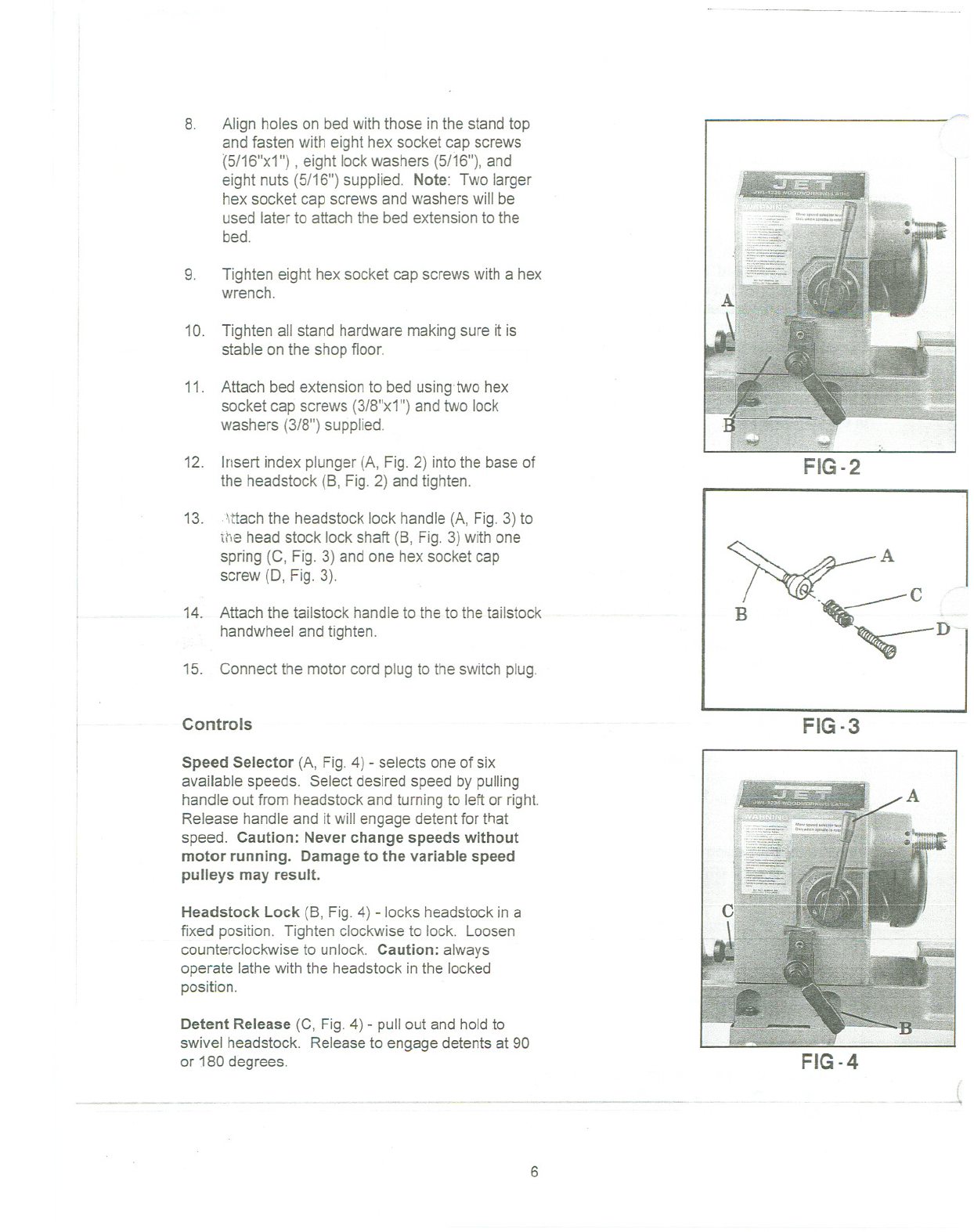

12. Insert index plunger(A, Fig. 2) into the base of

the headstock (B, Fig.2) and tighten.

13. \ttach the headstock lock handle (A, Fig.3) to

the head stock lock shaft (B, Fig. 3) with one

spring (C, Fig. 3) and one hex socket cap

screw (0, Fig. 3).

14. Attach the tailstock handleto the to the tailstock

handwheel and tighten.

15. Connect the motor cord plug to the switch plug.

Controls

Speed Selector (A, Fig. 4) - selects one of six

available speeds. Select desired speed by pulling

handle out from headstock and turning to left or right.

Release handle and it will engage detent for that

speed. Caution: Never change speeds without

motor running. Damage to the variable speed

pulleys may result.

Headstock Lock (B, Fig. 4) -locks headstockin a

fixed position. Tighten clockwiseto lock. Loosen

counterclockwise to unlock. Caution: always

operate lathewith the headstock inthe locked

position.

Detent Release (C, Fig. 4) - pull out and holdto

swivel headstock. Releaseto engage detents at 90

or 180 degrees.

,- ._~- .--.

..- _. ..~- - ~_. -- ,,-

6

...-.-----------------------

FIG-2

~A

B -~c --'

~D--

FIG-3

FIG-4