Operation

Lt,WARNING!

Use supplied face shield or similar protection

during all operations! Failure to comply may

cause serious injury!

Befere attempting work on regular stock, use scrap

material to get a feel for the machine.

Lathe Tools

Most turning is accomplished with special

woodworking chisels. They are available individually

or in sets. JET's wood turning chisel set ( optional

accessory - stock No. 709008) contains eight of the

most popular types of chisels:

5/16", 1/2", and 1" Gouge - a round nose, hollow

chisel for roughing and cove cutting

1/2" and 1" Skew - a double ground, flat, andend

ground to an angle used for smoothingcylinders and

cutting shoulders, beads, v-grooves, etc.

1/2" Diamond Point and 1/2" Round Nose - used

where their shape fits the contour of the work.

1/2" Parting Tool - double-groundchisel usedfor

cutting-off, straight incisions, and sizing cuts to any

diameter.

Spindle Turning

The majority of turning on a wood lathewill be

between centers, or spindle turning.

Centering the Work

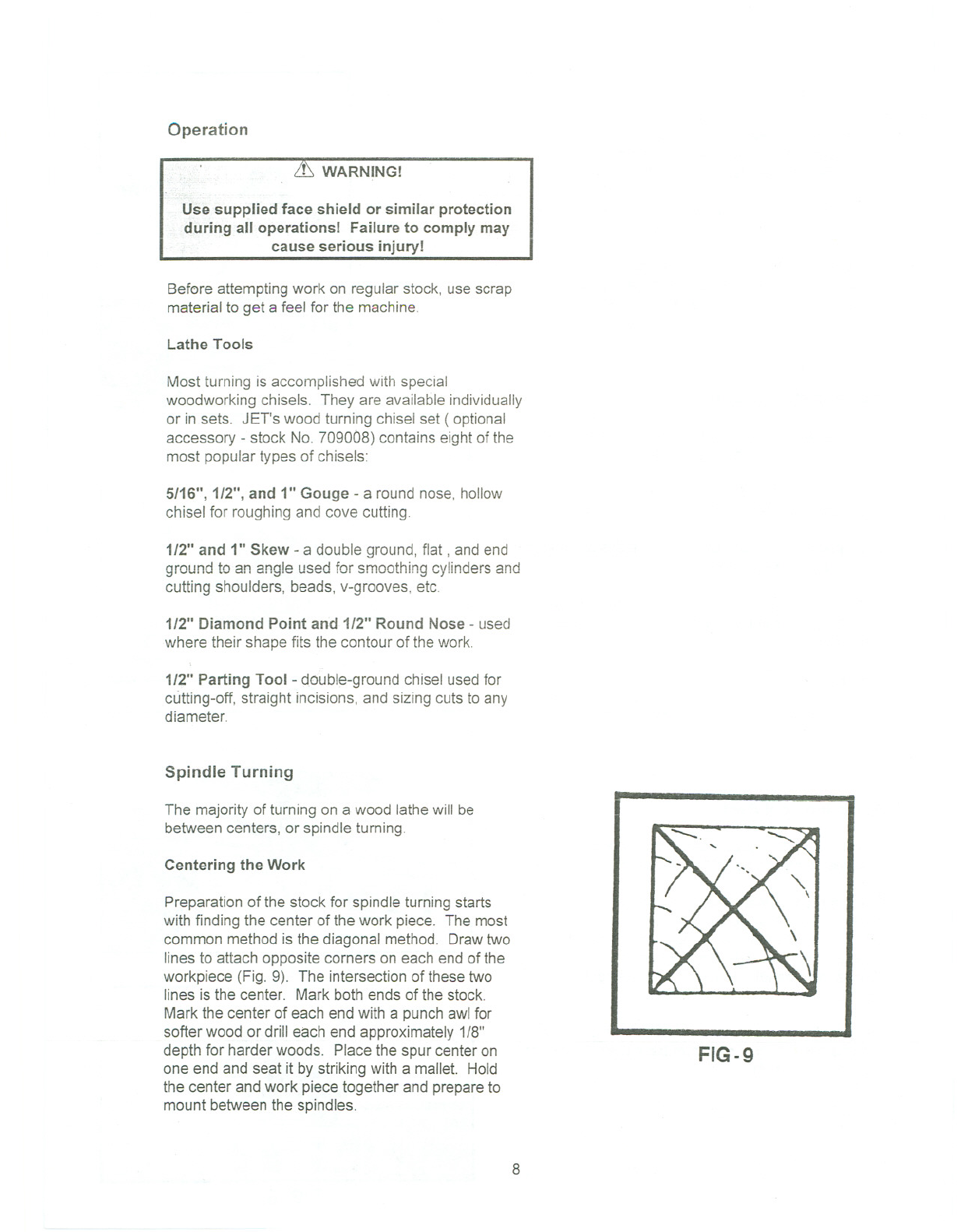

Preparation of the stock for spindle turning starts

with finding the center of the work piece. The most

common method is the diagonal method. Draw two

lines to attach opposite corners on each end of the

workpiece (Fig. 9). The intersection of these two

lines is the center. Mark both ends of the stock.

Mark the center of each end with a punch awl for

softer wood or drill each end approximately 1/8"

depth for harder woods. Place the spur center on

one end and seat it by striking with a mallet. Hold

the center and work piece together and prepare to

mount between the spindles.

FIG-9

8