The frame of the machine must be grounded. A

ground terminal marked with the symbol located at

the left side of the input box is provided for this pur-

pose. See the U.S. National Electrical Code for details

on proper grounding methods. Follow other grounding

instructions per the paragraph under “High Frequency

Interference Protection”.

On multiple voltage input machines, be

sure the

reconnect panel is connected per the following

instructions for the voltage being supplied to the

machine. See Figure 1 in the back of this manual.

• Failure to follow these instructions can cause imme-

diate failure of machine components.

------------------------------------------------------------------------

The PRO-CUT is shipped connected for the highest

nameplate input voltage. To change this connector

for a different input voltage, reconnect the power

straps to their respective terminals corresponding to

the input voltage used.

Fuse the input circuit with the recommended super lag

fuses. Choose an input and grounding wire size

according to local codes or use the Input Connection

table. “Delay type”

(1)

circuit breakers may be used in

place of fuses. Using fuses or circuit breakers smaller

than recommended may result in “nuisance” tripping

from machine inrush currents even if not cutting or

gouging at high currents.

(1)

Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit

breakers which have a delay in tripping action that decreases as the magni-

tude of the current increases.

AIR INPUT CONNECTIONS

A source of clean compressed air or nitrogen must be

supplied to the PRO-CUT. The supply pressure must

be between 70 and 120 psi (482 and 827 kPa). The

flow rate is approximately 4.7 cfm (133 l/min). Oil in

the air is a very severe problem and must be avoided.

Remove the plastic thread protector from the regulator

input port (located on the back of the machine). Use a

suitable gas connection fitting to make the connection

to the available air supply. The input port is a 1/4”

(6.3 mm) NPT thread. Tighten the air fitting to prevent

leakage but do not overtighten. The use of Teflon

tape to seal the connection is recommended.

Nitrogen from cylinders may be used with this

machine. The cylinder of nitrogen gas must be

equipped with a pressure regulator. No more than

120 psi (827 kPa) may be supplied to the regulator on

the machine. Install a hose between the regulator on

the gas cylinder and the gas inlet on the machine.

OUTPUT CONNECTIONS

Torch Connection

The PRO-CUT comes factory equipped with a cutting

torch.

Pictures of the torch along with the required replace-

ment parts are shown in the parts lists in the back of

this manual. The ends of the cable to be connected to

the power source are unique. Follow the applicable

instructions as given in Figure 2 in the back of this

manual.

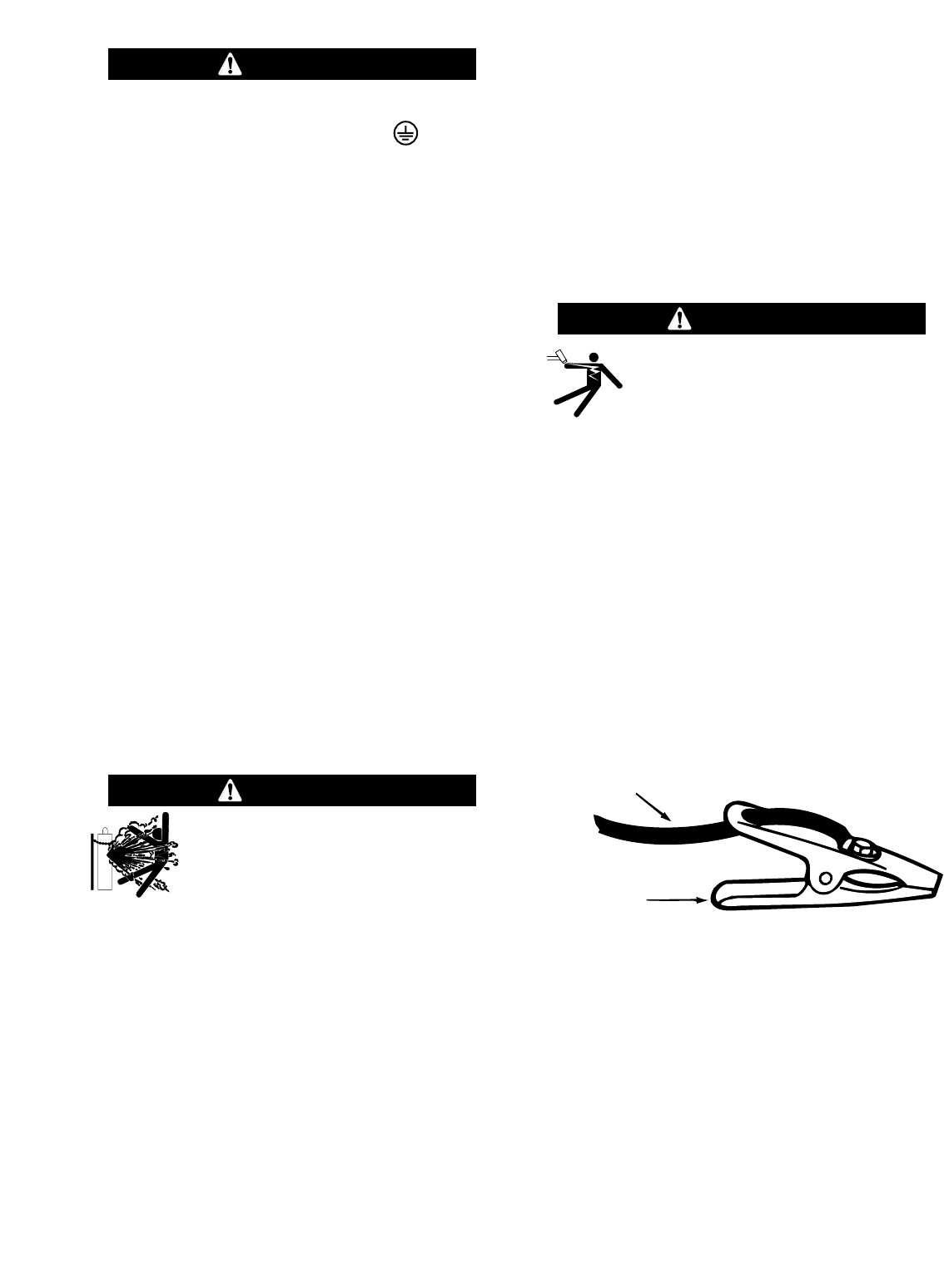

Work Cable and Clamp Installation

Attach the work clamp to the work cable (which

extends from the front of the machine) as shown.

Tighten nut and bolt securely.

OPERATING INSTRUCTIONS

Sequence of events:

A. Turn on the line power.

B. Connect the air supply to the machine.

C. Turn the power switch on.

-The green “Power On” LED should begin to

glow.

– 11 –

HIGH FREQUENCY SHOCK CAN

CAUSE INJURY OR FALL.

• Keep the cutting torch and cables in

good condition.

•

Secure yourself in position to avoid a fall.

----------------------------------------------------------------------------

WARNING

CAUTION

Work cable

Work clamp

CYLINDER may explode if damaged

• Keep cylinder upright and chained to a

fixed support.

• Keep cylinder away from areas where it

may be damaged.

• Never lift equipment with cylinder attached.

• Never allow the cutting torch to touch cylinder.

• Keep cylinder away from live electrical circuits.

• Maximum inlet pressure 120 psig (827 kPa).

------------------------------------------------------------------------

WARNING