#** R')" %*

+)&,#*&&+ %

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

#@42=#:?4@=?FE9@C:K65:6=5*6CG:4624:=:EJ for technical troubleshooting assistance before you proceed.

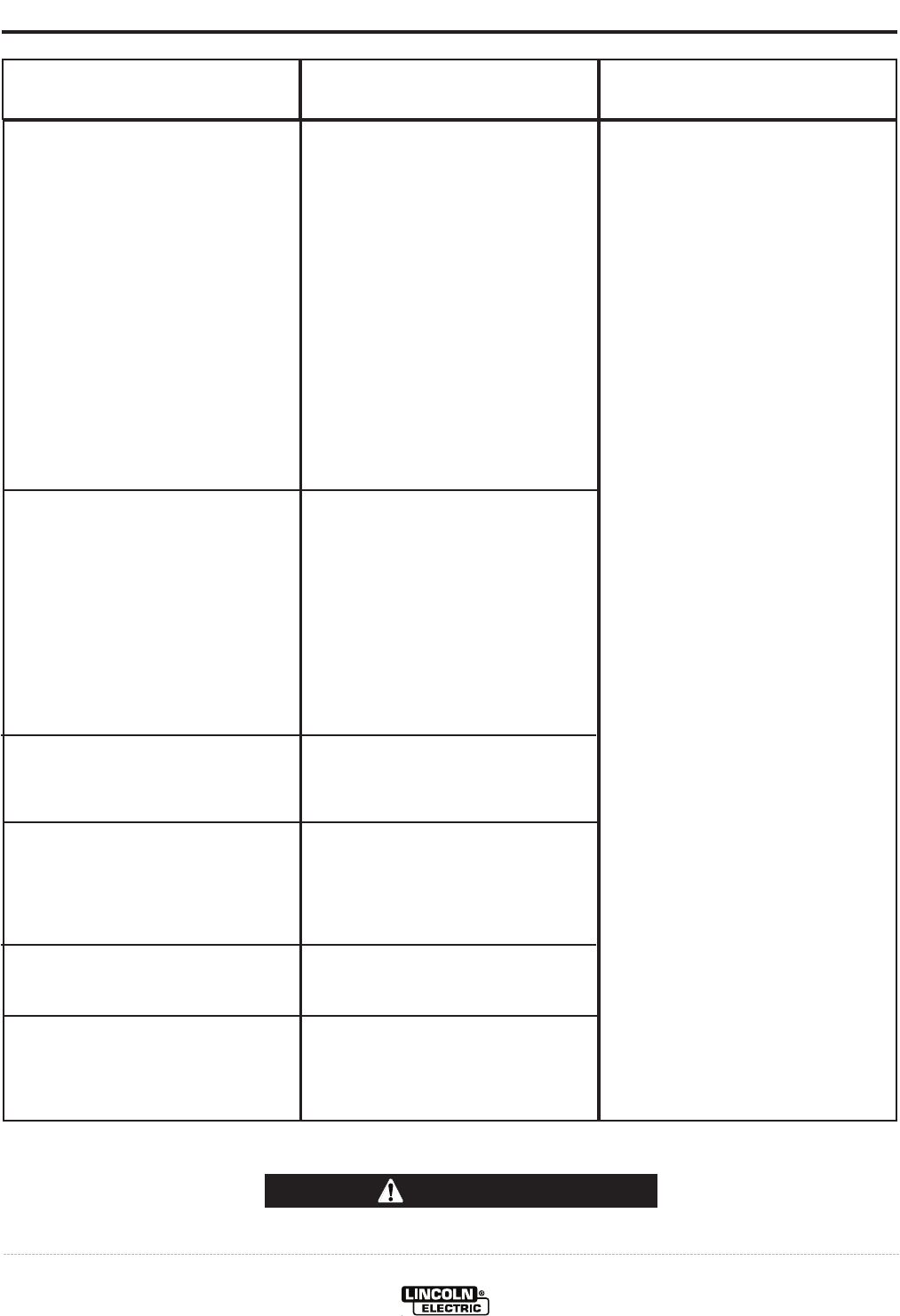

,+ &%

')&#$*

*0$'+&$*

'&** #

,*

)&$$%

&,)*&+ &%

Machine fails to hold the output

(heat) consistently.

Welder starts but fails to generate

current.

Welding arc is loud and spatters

excessively.

Welding current too great or too

small compared to indication on

the dial.

Arc continuously pops out.

1. Rough or dirty commutator.

2. Brushes may be worn down to

Limit.

3. Field circuit may have variable

resistance connection or inter-

mittent open circuit due to

loose connection or broken

wire.

4. Electrode lead or work lead

connection may be poor.

5. Wrong grade of brushes may

have been installed on gener-

ator.

6. Field rheostat may be making

poor contact and overheating.

1. Generator or exciter brushes

may be loose or missing.

2. Exciter may not be operating.

3. Field circuit of generator or

exciter may be open.

4. Exciter may have lost excita-

tion.

5. Series field and armature cir-

cuit may be open-circuited.

1. Current setting may be too

high.

2. Polarity may be wrong.

1. Exciter output low causing low

output compared to dial indica-

tion.

2. Operating speed too low or too

high.

1. “Current Range Selector”

switch may be set at an inter-

mediate position.

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

@?E24E J@FC =@42= #:?4@=?

FE9@C:K65:6=5*6CG:4624:=:EJ