– 11 –

3. Proper placement of the equipment on the

undercarriage to ensure stability side to side and

front to back when being moved and when

standing by itself while being operated or serviced.

4. Typical conditions of use, i.e. travel speed,

roughness of surface on which the trailer will be

operated, environmental conditions & likely

maintenance.

5. Conformance with federal, state and local laws.

(1)

(1)

Consult applicable federal, state and local laws regarding specific

requirements for use on public highways.

Polarity Control & Cable Sizes

With the engine off, connect the electrode and work

cables of the appropriate size (see the following table)

to the studs located on the fuel tank mounting rail.

For Positive polarity, connect the electrode cable to

the terminal marked “Positive”. For Negative

polarity, connect the electrode cable to the “Negative”

stud. These connections should be checked

periodically and tightened if necessary.

When welding at a considerable distance from the

welder, be sure you use ample size welding cables.

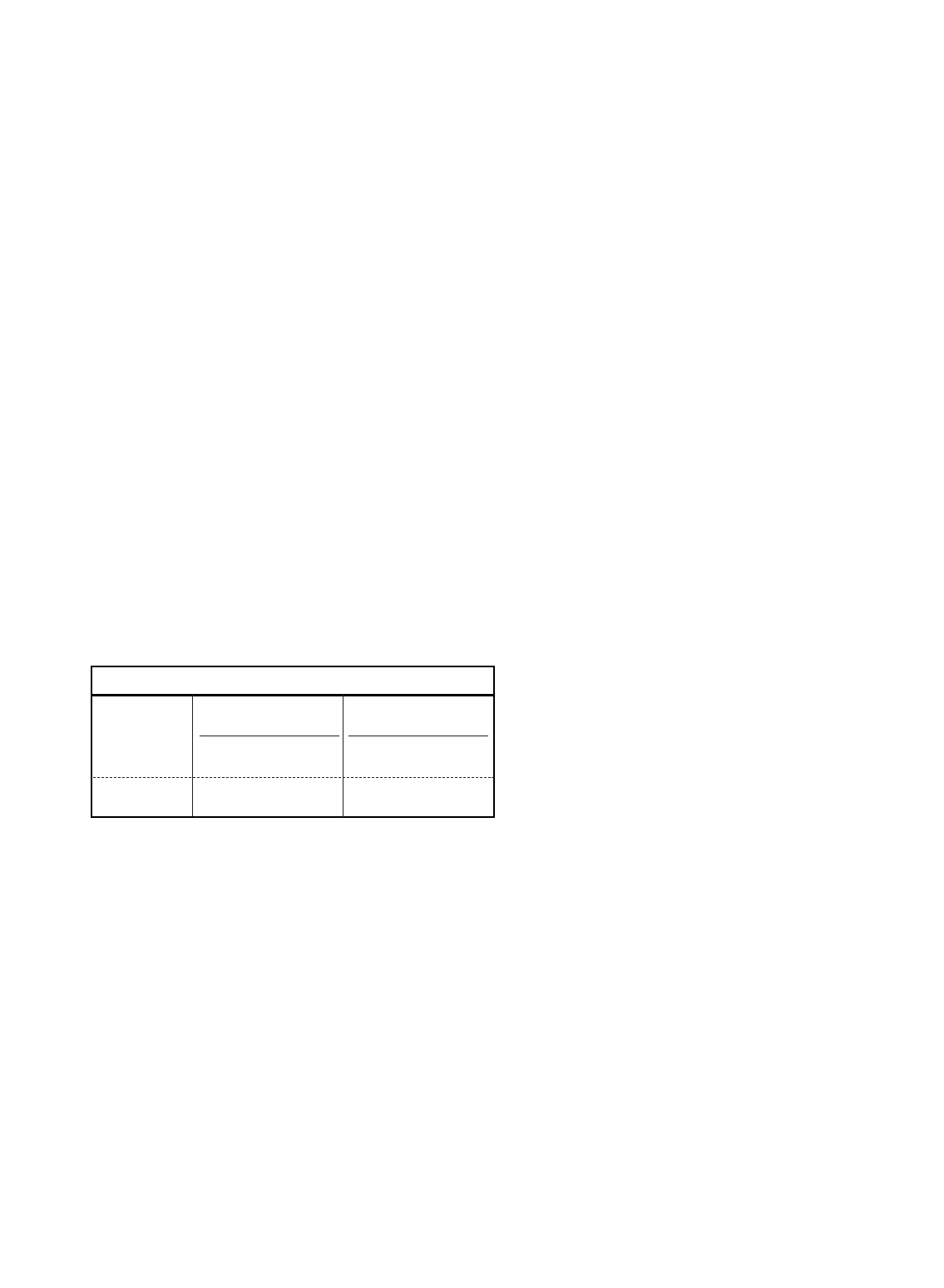

Recommended Copper Cable Sizes

Up to 200 ft

200-250 ft

250 Amps

@ 60% Duty Cycle

1

1/0

350 Amps

@ 25% Duty Cycle

2/0

3/0