– 14 –

When a forceful “digging” arc is required, usually for

vertical and overhead welding, use a higher “Current

Range Selector” setting and lower open circuit

voltage. For example: to obtain 175 amps and a

forceful arc, set the “Current Range Selector” to the

240-160 position and the “Fine Current Adjustment”

setting to get 175 amps.

DO NOT attempt to set the “Current Range Selector”

between the five points designated on the nameplate.

------------------------------------------------------------------------

These switches have a spring loaded cam which

almost eliminates the possibility of setting this switch

between the designated points.

Idler Operation

Start the engine with the “Idler Control” switch in

“High Idle” position. Allow it to run at high idle speed

for several minutes to warm the engine. The

operating speeds are as follows:

The idler is controlled by an “Idler Control” toggle

switch on the welder control panel. The switch has

two positions as follows:

1. In the “High” position, the idler is off, and the

engine runs at the high speed controlled by the

governor.

2. In the “Automatic” / position, the

idler operates as follows:

a. When welding or drawing power for lights or

tools (approximately 100-150 watts minimum)

from the receptacles, the engine operates at full

speed.

b. When welding ceases or the power load is

turned off, a preset time delay of about 15

seconds starts. This time delay cannot be

adjusted.

c. If the welding or power load is not re-started

before the end of the time delay, the idler

reduces the engine to low idle speed.

ORDERING

INFO.

ENGINE FULL

LOAD

HIGH

IDLE

LOW

IDLE

K1314-

ALL

Perkins

Diesel

1725 1800 1350

WELDER OPERATION

Duty Cycle

The NEMA output rating of the 350-SA is 250

amperes at 30

(1)

arc volts on a 60% duty cycle. Duty

cycle is based on a ten minute period; thus, the

welder can be loaded at rated output for six minutes

out of every ten minute period.

(1)

The Lincoln ‘plus output” rating at 60% duty cycle

is 250 amperes at 40 volts.

Control of Welding Current

DO NOT TURN THE “CURRENT RANGE

SELECTOR” WHILE WELDING because the

current may arc between the contacts and damage

the switch.

------------------------------------------------------------------------

The “Current Range Selector” provides five

overlapping current ranges. The “Fine Current

Adjustment” adjusts the current from minimum to

maximum within each range. Open circuit voltage is

also controlled by the “Fine Current Adjustment”

permitting control of the arc characteristics.

A high open circuit voltage setting provides the soft

“buttering” arc with best resistance to pop-outs

preferred for most welding. To get this characteristic,

set the “Current Range Selector” to the lowest setting

that still provides the current you need and set the

“

Fine Current Adjustment” near maximum. For example:

to obtain 175 amps and a soft arc, set the “Current

Range Selector” to the 190-120 position and then adjust

the “Fine Current Adjustment” for 175

amps.

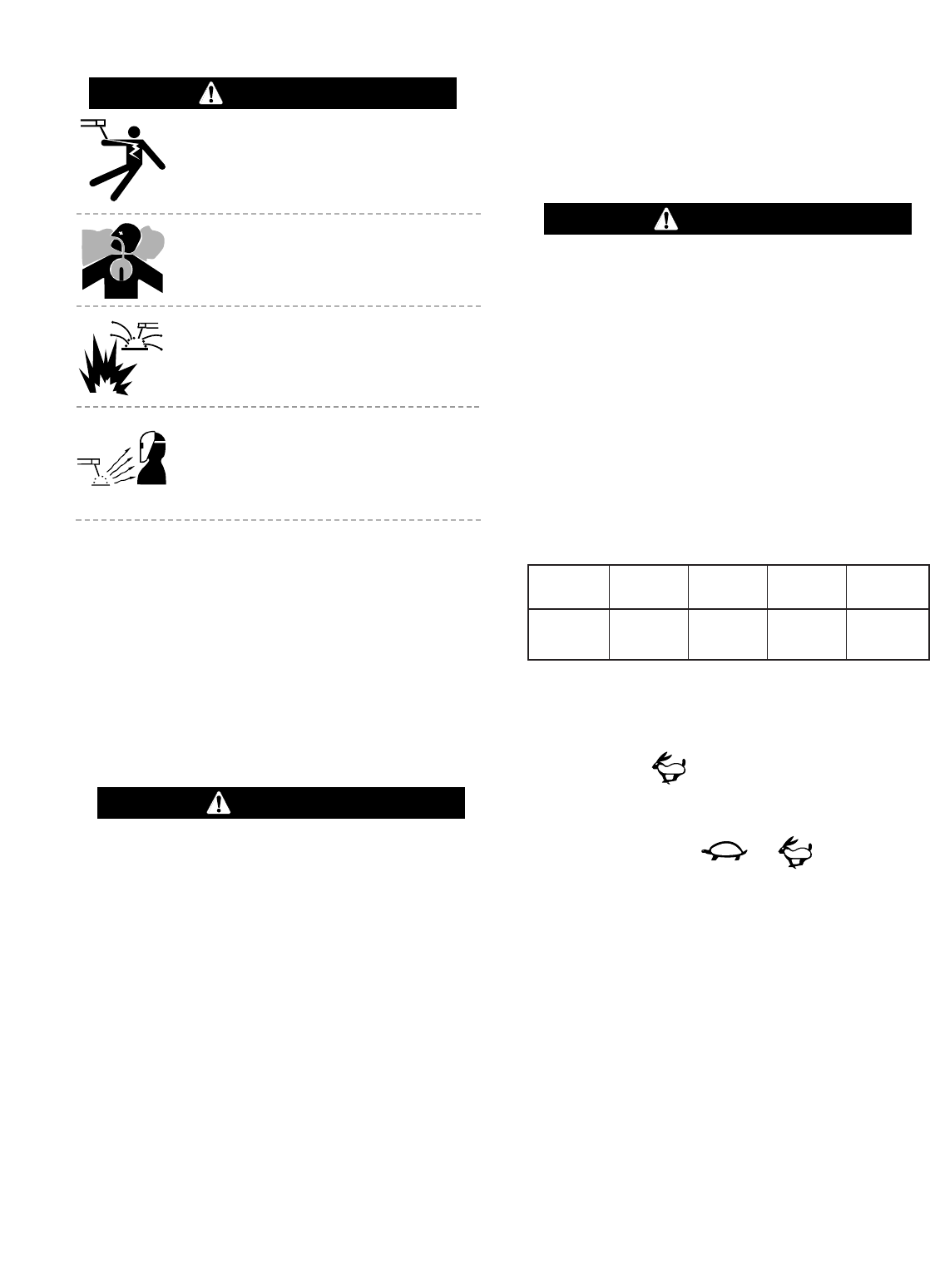

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and ground.

FUMES & GASES can be dangerous.

• Keep your head out of the fumes.

• Use ventilation or exhaust to remove

fumes from breathing zone.

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

ARC RAYS can burn.

• Wear eye, ear, and body protection.

WARNING

CAUTION

CAUTION